Abstract

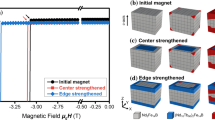

The grain boundary diffusion (GBD) process with rare-earth hydride was performed to increase the coercivity of hydrogenation–disproportionation–desorption–recombination (HDDR) powder. Before the GBD process, we investigated the effect of post-annealing of the initial HDDR powder on its magnetic properties. Low-temperature annealing reduced the coercivity of the HDDR powder. However, the coercivity decline decreased with increasing annealing temperature, becoming similar to that of the initial powder at 900°C. After the GBD process at 850°C for 1 h, the coercivity increased by about 4 kOe with 4 wt.% NdH x -Cu, forming a thick and continuous grain boundary phase. In addition, the coercivity and remanence of the HDDR powder produced by the GBD process with NdH x -Cu were higher when using NdH x in spite of the same amount of diffusion as at 2 wt.%.

Similar content being viewed by others

References

O. Gutfleisch, M.A. Willard, E. Brück, C.H. Chen, S. Sankar, and J.P. Liu, Adv. Mater. 23, 821 (2011).

K. Hono and H. Sepehri-Amin, Scr. Mater. 67, 530 (2012).

W. Li, T. Ohkubo, K. Hono, T. Nishiuchi, and S. Hirosawa, Appl. Phys. Lett. 93, 052505 (2008).

G. Hrkac, T. Woodcock, K. Butler, L. Saharan, M. Bryan, T. Schrefl, and O. Gutfleisch, Scr. Mater. 70, 35 (2014).

H. Sepehri-Amin, T. Ohkubo, T. Nishiuchi, S. Hirosawa, and K. Hono, Scr. Mater. 63, 1124 (2010).

L. Liu, H. Sepehri-Amin, T. Ohkubo, M. Yano, A. Kato, T. Shoji, and K. Hono, J. Alloys Compd. 666, 432 (2016).

T. Kim, S. Lee, H. Kim, M. Lee, and T. Jang, Acta Mater. 93, 95 (2015).

K. Bae, T. Kim, S. Lee, H. Kim, M. Lee, and T. Jang, J. Alloys Compd. 612, 183 (2014).

A. Gabay, M. Marinescu, W. Li, J. Liu, and G. Hadjipanayis, J. Appl. Phys. 109, 083916 (2011).

T. Akiya, J. Liu, H. Sepehri-Amin, T. Ohkubo, K. Hioki, A. Hattori, and K. Hono, Scr. Mater. 81, 48 (2014).

H. Sepehri-Amin, T. Ohkubo, S. Nagashima, M. Yano, T. Shoji, A. Kato, T. Schrefl, and K. Hono, Acta Mater. 61, 6622 (2013).

H. Sepehri-Amin, L. Liu, T. Ohkubo, M. Yano, T. Shoji, A. Kato, T. Schrefl, and K. Hono, Acta Mater. 99, 297 (2015).

T. Akiya, J. Liu, H. Sepehri-Amin, T. Ohkubo, K. Hioki, A. Hattori, and K. Hono, J. Appl. Phys. 115, 17A766 (2014).

Z. Lin, J. Han, M. Xing, S. Liu, R. Wu, C. Wang, Y. Zhang, Y. Yang, and J. Yang, Appl. Phys. Lett. 100, 052409 (2012).

H. Sepehri-Amin, J. Liu, T. Ohkubo, K. Hioki, A. Hattori, and K. Hono, Scr. Mater. 69, 647 (2013).

R. Mottram, B. Davis, V. Yartys, and I. Harris, Int. J. Hydrogen Energy 26, 441 (2001).

P. Liu, T. Ma, X. Wang, Y. Zhang, and M. Yan, J. Alloys Compd. 628, 282 (2015).

H.R. Cha, K.W. Jeon, J.G. Yu, H.W. Kwon, Y.D. Kim, and J.G. Lee, J. Alloys Compd. 693, 744 (2017).

H.R. Cha, J.H. Yu, Y.K. Baek, H.W. Kwon, Y.D. Kim, and J.G. Lee, J. Magn. 19, 49 (2014).

W. Li, T. Ohkubo, and K. Hono, Acta Mater. 57, 1337 (2009).

T. Kim, S. Lee, S. Namkumg, and T. Jang, J. Alloys Compd. 537, 261 (2012).

K. Takagi, M. Akada, R. Soda, and K. Ozaki, J. Magn. Magn. Mater. 393, 461 (2015).

H. Sepehri-Amin, T. Ohkubo, T. Shima, and K. Hono, Acta Mater. 60, 819 (2012).

H. Okamoto, J. Phase Equilb. Diffus. 36, 183 (2015).

T. Kim, S. Lee, M. Lee, T. Jang, J.W. Kim, Y. Do Kim, and H. Kim, Acta Mater. 66, 12 (2014).

J. Liu, H. Sepehri-Amin, T. Ohkubo, K. Hioki, A. Hattori, T. Schrefl, and K. Hono, Acta Mater. 82, 336 (2015).

Acknowledgements

This study was supported by the Korea Institute of Materials Science (KIMS) internal R&D program (Grant No. PNK5590) and Industrial Strategic Technology Development Program (10080382) funded by the Ministry of Trade, Industry & Energy (MI, Korea).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cha, HR., Yoo, JG., Baek, YK. et al. Coercivity Enhancement of Nd-Fe-B HDDR Powder by Grain Boundary Diffusion Process with Rare-Earth Hydride. JOM 70, 661–665 (2018). https://doi.org/10.1007/s11837-018-2792-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-2792-5