Abstract

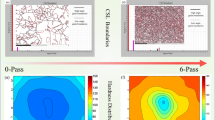

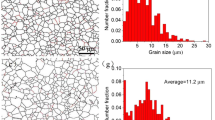

Equal channel angular pressing (ECAP) was performed on extruded pure Mg, which was clad with a drilled pure Fe coat through an ECAP die to produce a pure Mg sample without obvious cracks at room temperature. After one-pass ECAP, the grain size decreased because of basal slip activation during the dynamic plastic deformation but the microstructure became inhomogeneous. The deformed texture was less scattered and inclined by ~20° from the normal direction toward the extruded direction, and low angle boundaries increased continuously. The mechanical properties decreased slightly as a result of the combined effect from a more refined microstructure and a weaker texture.

Similar content being viewed by others

References

S. Kamado and Y. Kojima, Mater. Sci. Forum 546–549, 55 (2007).

D. Brungs, Mater. Des. 18, 285 (1997).

R.W.K. Honeycombe, The Plastic Deformation of Metals (London: Edward Arnold, 1968), p. 20.

R.Z. Valiev and T.G. Langdon, Prog. Mater. Sci. 51, 881 (2006).

A. Muralidhar, S. Narendranath, and H. Shivananda Nayaka, J. Mag. Alloys 1, 336 (2013).

M.Z. Bian, Y.L. Li, M. Mathesh, D. Abreu, and N.D. Nam, J. Alloys Compd. 578, 369 (2013).

R. Kaibyshev, A. Galiev, Y. Huang, R.B. Figueiredoand, and O. Sitdikov, Nanostructured Mater. 6, 621 (1995).

Y. Huang, R.B. Figueiredo, and T. Baudin, Adv. Eng. Mater. 14, 1018 (2012).

R. Wadsack, R. Pippan, and B. Schedler, Fusion Eng. Des. 66–68, 265 (2003).

G. Sakai, Z. Horita, and T.G. Langdon, Mater. Sci. Eng. A 393, 344 (2005).

S.V. Dobatkin, E.N. Bastarache, and G. Sakai, Mater. Sci. Eng. A 408, 141 (2005).

R.Z. Valiev, Y. Estrin, and Z. Horita, JOM 58, 33 (2006).

Q. Guo, H.G. Yan, and Z.H. Chen, Mater. Charact. 2, 162 (2007).

A. Bhowmik, S. Biswas, and S.S. Dhinwal, Mater. Sci. Forum 702–703, 774 (2012).

R.Z. Valiev, Nature 419, 887 (2002).

F.S.J. Poggiali, R.B. Figueiredo, M.T.P. Aguilar, and P.R. Cetlin J. Mater. Res. Technol. 2, 30 (2013).

C.Y. Lin, H.Y. Bor, C.G. Chao, and T.F. Liu, J. Alloys Compd. 578, 26 (2013).

K.E. Jeong, B.C. Hee, S.M. Hong, K. Taek-Soo, and K.H. Seop, Mater. Trans. 49, 1006 (2008).

B. Beausir, S. Suwas, L. Tóth, K.W. Neale, and J.J. Fundenberger, Acta Mater. 56, 200 (2008).

S.X. Ding, W.T. Lee, and C.P. Chang, Scr. Mater. 59, 1006 (2008).

K. Xia, J.T. Wang, X. Wu, G. Chen, and M. Gurvan, Mater. Sci. Eng. A 410, 324 (2005).

S. Biswas, S.S. Dhinwal, and S. Suwas, Acta Mater. 58, 3247 (2010).

H. Kitahara, F. Maruno, M. Tsushida, and S. Ando, Mater. Sci. Eng. A 590, 274 (2014).

X. Yang, H. Miura, and T. Sakai, Mater. Trans. 46, 2981 (2005).

W.J. Kim, S.I. Hong, Y.S. Kim, S.H. Min, H.T. Jeong, and J.D. Lee, Acta Mater. 51, 3293 (2003).

M. Mabuchi, Y. Chino, and H. Iwasaki, Metall. Mater. Trans. 42, 1182 (2001).

J.Z. Li, W. Xu, X.L. Wu, H. Ding, and K. Xia, Mater. Sci. Eng. A 528, 5993 (2011).

W.J. Kim and H.G. Jeong, Mater. Sci. Forum 419–422, 201 (2003).

T. Liu, W. Zhang, S.D. Wu, C.B. Jiang, S.X. Li, and Y.B. Xu, Mater. Sci. Eng. A 360, 345 (2003).

V.M. Segal, Mater. Sci. Eng. A 197, 157 (1995).

Acknowledgements

This research was completely supported by the National Natural Science Foundation of China (No. 51474152).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lei, W., Liang, W., Wang, H. et al. Evolution of Texture and Mechanical Properties of Pure Mg Processed by ECAP at Room Temperature. JOM 69, 2297–2301 (2017). https://doi.org/10.1007/s11837-017-2497-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2497-1