Abstract

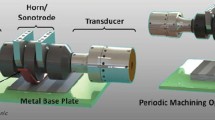

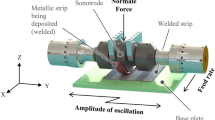

Ultrasonic additive manufacturing (UAM) is a three-dimensional metal printing technology which uses high-frequency vibrations to scrub and weld together both similar and dissimilar metal foils. There is no melting in the process and no special atmosphere requirements are needed. Consequently, dissimilar metals can be joined with little to no intermetallic compound formation, and large components can be manufactured. These attributes have the potential to transform manufacturing of nuclear reactor core components such as control elements for the High Flux Isotope Reactor at Oak Ridge National Laboratory. These components are hybrid structures consisting of an outer cladding layer in contact with the coolant with neutron-absorbing materials inside, such as neutron poisons for reactor control purposes. UAM systems are built into a computer numerical control (CNC) framework to utilize intermittent subtractive processes. These subtractive processes are used to introduce internal features as the component is being built and for net shaping. The CNC framework is also used for controlling the motion of the welding operation. It is demonstrated here that curved components with embedded features can be produced using a five-axis code for the welder for the first time.

Similar content being viewed by others

Notes

Al-6061 H18 tapes were made by cold rolling annealed Al 6061 to a H18 temper.

References

R. Cheverton and T. Sims, Report No. 4621: HFIR Core Nuclear Design, Oak Ridge National Laboratory, 1971.

D. Selby and G. Smith: Nucl. News (La Grange Park, Ill.), 53, 35 (2010).

G. Adamson Jr, Report No. 4342: Fabrication Procedures for the Initial High Flux Isotope Reactor Fuel Elements, Oak Ridge National Laboratory, 1969.

D. White, Adv. Mater. Processes 161, 64 (2003).

K. Graff, M. Short and M. Norfolk, Solid Freeform Fabrication Symposium of Proceedings (2010), pp. 82–89.

M. Norfolk and Hilary Johnson, JOM 67, 655 (2015).

E. Herderick, Mater. Sci. Technol. Conf. Exhib. 2, 1413 (2011).

W.J. Sames, F.A. List, S. Pannala, R.R. Dehoff, and S.S. Babu, Int. Mater. Rev. 61, 315 (2016).

M. Sriraman, M. Gonser, H. Fujii, S. Babu, and M. Bloss, J. Mater. Process. Technol. 211, 1650 (2011).

J. Sietins, Exploring Diffusion of Ultrasonically Consolidated Aluminum and Copper Films Through Scanning and Transmission Electron Microscopy (PhD thesis, University of Delaware, 2014).

A. Truog, Bond Improvement of Al/Cu Joints Created by Very High Power Ultrasonic Additive Manufacturing (MS thesis, The Ohio State University, 2012).

T. Abe and H. Sasahara, Precis. Eng. 45, 387 (2016).

Report No. 6FC5095-0AB10-0BP1: Milling with Sinumerick: 5-axis machining, Siemens, 2009.

K. Terrani, S.S. Babu, C. Bryan, J. Kiggans, D. Pinkston, N. Sridharan, M. Gussev and M. Norfolk, Trans. Am. Nucl. Soc. 113 (2015).

P. Wolcott, A. Hehr, and M. Dapino, J. Mater. Res. 29, 2055 (2014).

A. Hehr, P.J. Wolcott, and M.J. Dapino, Rapid Prototyp. J. 22, 377 (2016).

N. Sridharan, M. Gussev, R. Seibert, C. Parish, M. Norfolk, K. Terrani, and S.S. Babu, Acta Mater. 117, 228 (2016).

P. Wolcott, A. Hehr, C. Pawlowski, and M. Dapino, J. Mater. Process. Technol. 233, 44 (2016).

M. Gussev, N. Sridharan, M. Norfolk, K. Terrani and S. Babu (Oak Ridge National Lab, The University of Tennessee, Fabrisonic LLC, unpublished research, 2016).

K. Terrani, J. Kiggans, N. Sridharan, M. Gussev, M. Norfolk, J. Burns, D. Chandler, S. Babu, C. Bryan, D. Pinkston, Trans. Am Nucl. Soc. 114 (2016).

Acknowledgements

Research sponsored by the Laboratory Directed Research and Development Program of Oak Ridge National Laboratory, managed by UT-Battelle, LLC, for the U. S. Department of Energy. The aid and technical insight of James Kiggans, Ronald Swain, Troy Jensen, Dan Pinkston and Chris Bryan at ORNL is gratefully acknowledged. HFIR is funded by the Department of Energy Office of Science, Basic Energy Sciences.

Author information

Authors and Affiliations

Corresponding author

Additional information

This manuscript has been authored by UT-Battelle, LLC under Contract No. DE-AC05-00OR22725 with the U.S. Department of Energy. The United States Government retains and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, world-wide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States Government purposes. The Department of Energy will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan).

Rights and permissions

About this article

Cite this article

Hehr, A., Wenning, J., Terrani, K. et al. Five-Axis Ultrasonic Additive Manufacturing for Nuclear Component Manufacture. JOM 69, 485–490 (2017). https://doi.org/10.1007/s11837-016-2205-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-2205-6