Abstract

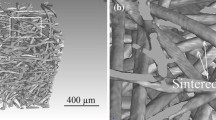

Stainless steel fiber felts are important porous stainless steel products for a variety of industry applications. A systematic study of the sintering of 28-µm stainless steel fibers has been conducted for the first time, assisted with synchrotron radiation experiments to understand the evolution of the sintered joints. The critical sintering conditions for the formation of bamboo-like grain structures in the fiber ligaments were identified. The evolution of the number density of the sintered joints and the average sintered neck radius during sintering was assessed based on synchrotron radiation experiments. The optimum sintering condition for the fabrication of high strength and ductile 28-µm-diameter stainless steel fiber felts was determined to be sintering at 1000°C for 900 s. Sintering under this optimum condition increased the tensile strength of the as-sintered stainless steel fiber felts by 50% compared to conventional sintering (1200°C for 7200 s), in addition to much reduced sintering cycle and energy consumption.

Similar content being viewed by others

References

Q.B. Ao, H.P. Tang, J.Y. Wang, J.L. Zhu, H. Zhi, and J. Ma, An Acoustic Enclosure, Chinese patent CN: ZL 201320453282.1.

H. Zhi, H.P. Tang, J.L. Zhu, J.Z. Wang, Q.B. Ao, and J. Ma, Preparation Method of Composite Porous Surface with Metal Fiber for Heat Transfer, Chinese patent CN: ZL 201110396522.4.

B. Zhou, W. Yuan, J.Y. Hu, Y. Tang, L.S. Lu, and B.H. Yu, Trans. Nonferrous Met. Soc. China 25, 2003 (2015).

T.W. Shyr, J.W. Shie, S.J. Huang, S.T. Yang, and W.S. Hwang, Mater. Chem. Phys. 122, 273 (2010).

W.Q. Li and Z.G. Qu, Appl. Therm. Eng. 86, 119 (2015).

J.Z. Wang, Q.B. Ao, H.P. Tang, and T.F. Bao, Int. J. Mod. Phys. B, 29, 1540002-1-7 (2015).

H.P. Tang, J.Z. Wang, Q.B. Ao, and H. Zhi, Rare Metal Mat. Eng. 44, 1821 (2015).

J.Z. Wang, H.P. Tang, J.L. Zhu, Q.B. Ao, H. Zhi, and J. Ma, Rare Metal Mat. Eng. 42, 2433 (2013).

Z.P. Xi and H.P. Tang, Sintered Metal Porous Materials, 1st ed. (Metallurgical Industry Press, Beijing, 2009), pp. 217-231;242-255 (in Chinese).

Z.P. Xi, J.L. Zhu, H.P Tang, Q.B. Ao, H. Zhi, JY. Wang, and C. Li, Mater. 4, 816 (2011).

C.J. Zhang, W. Zhou, Q.H. Wang, H.B. Wang, Y. Tang, and K.S. Hui, Appl. Surf. Sci. 276, 377 (2013).

M.Q. Pan, H.F. Peng, Q.Y. Wu, and X.L. Wei, Trans. Nonferrous Met. Soc. China 25, 1215 (2015).

J.Z. Wang, Z.P. Xi, H.P. Tang, W.D. Huang, Ji-lei Zhu, and Qing-bo Ao, Trans. Nonferrous Met. Soc, China, 23, 1046 (2013).

Q.B. Ao, H.P. Tang, J.Z. Wang, H. Zhi, J. Ma, and B. Li, Rare Metal Mat. Eng. 43, 2344 (2014).

J.L. Zhu, H.P. Tang, J. Sun, J.Z. Wang, Q.B. Ao, and H. Zhi, Procedia Eng. 27, 775 (2012).

W.G. Nan, Y.S. Wang, Y. Ge, and J.Z. Wang, Powder Technol. 261, 210 (2014).

B. Herzhaft, E. Guazzelli, M.B. Mackaplow, and E.S. Shaqfeh, Phys. Rev. Lett. 77, 290 (1996).

H.L. Liu, J.Z. Wang, and H.P. Tang, Rare Metal Mat. Eng. 14, 2023 (2014).

P. Feng, Y. Liu, Y. Wang, K. Li, X.Y. Zhao, H.P. Tang, and J. Cent, South Univ. 22, 793 (2015).

Y.N. Yu, Metallography Principle, 2nd ed. (Metallurgical Industry Press, Beijing, 2013), pp. 733 (in Chinese).

Acknowledgements

The authors gratefully acknowledge the financial support received from the National Natural Science Foundation of China (51134003), the Youth Scientific Star Project of Shaanxi Province (2014KJXX-24), the Opening Project of the State Key Laboratory of Explosion Science and Technology (Beijing Institute of Technology) (KFJJ15-02M) and the Key Scientific and Technological Innovation Team Project of Shaanxi Province (2015KCT-11). Furthermore, the authors wish to sincerely thank the support of the Shanghai Synchrotron Radiation Facility (SSRF).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, J.Z., Tang, H.P., Qian, M. et al. Fabrication of High Strength and Ductile Stainless Steel Fiber Felts by Sintering. JOM 68, 890–898 (2016). https://doi.org/10.1007/s11837-015-1803-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1803-z