Abstract

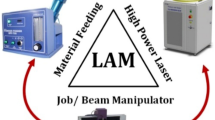

While metal additive manufacturing (AM) technology has clear benefits, there are still factors preventing its adoption by industry. These factors include the high cost of metal AM systems, the difficulty for machinists to learn and operate metal AM machines, the long approval process for part qualification/certification, and the need for better process controls; however, the high AM system cost is the main barrier deterring adoption. In this paper, we will discuss an America Makes-funded program to reduce AM system cost by combining metal AM technology with conventional computerized numerical controlled (CNC) machine tools. Information will be provided on how an Optomec-led team retrofitted a legacy CNC vertical mill with laser engineered net shaping (LENS®—LENS is a registered trademark of Sandia National Labs) AM technology, dramatically lowering deployment cost. The upgraded system, dubbed LENS Hybrid Vertical Mill, enables metal additive and subtractive operations to be performed on the same machine tool and even on the same part. Information on the LENS Hybrid system architecture, learnings from initial system deployment and continuing development work will also be provided to help guide further development activities within the materials community.

Similar content being viewed by others

References

All-in-1:Laser deposition welding and milling (DMG Mori, 2015). http://us.dmgmori.com/products/lasertec/lasertec-additivemanufacturing/lasertec-65-3d#Downloads. Accessed 10 Nov 2015.

T. Wohlers and T. Caffrey, Wohlers Report 2015, 20th Anniversary ed., 130 (2015).

R. Berger, Roland Berger Strategy Consultants, Munich, November 2013.

A.R. Nassar, J.S. Keist, E.W. Reutzel, and T.J. Spurgeon, Addit. Manuf. 6, 39 (2015).

A. Sun, E. Kannatey-Asibu Jr., and M. Gartner, J. Laser Appl. 11, 153 (1999).

Acknowledgements

Funding for this project was received from the Office of the Secretary of Defense, Manufacturing and Industrial Base Policy through a cooperative agreement with the Air Force Research Laboratory (FA8650-12-2-7230).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vartanian, K., McDonald, T. Accelerating Industrial Adoption of Metal Additive Manufacturing Technology. JOM 68, 806–810 (2016). https://doi.org/10.1007/s11837-015-1794-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1794-9