Abstract

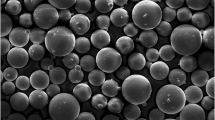

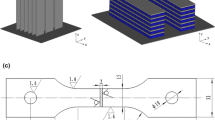

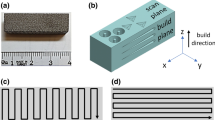

Achieving a high surface finish is a major challenge for most current metal additive manufacturing processes. We report the first quantitative study of the influence of as-built surface conditions on the tensile properties of Ti-6Al-4V produced by selective electron beam melting (SEBM) in order to better understand the SEBM process. Tensile ductility was doubled along with noticeable improvements in tensile strengths after surface modification of the SEBM-fabricated Ti-6Al-4V by chemical etching. The fracture surfaces of tensile specimens with different surface conditions were characterised and correlated with the tensile properties obtained. The removal of a 650-μm-thick surface layer by chemical etching was shown to be necessary to eliminate the detrimental influence of surface defects on mechanical properties. The experimental results and analyses underline the necessity to modify the surfaces of SEBM-fabricated components for structural applications, particularly for those components which contain complex internal concave and convex surfaces and channels.

Similar content being viewed by others

References

G. Chahine, M. Koike, T. Okabe, P. Smith, and R. Kovacevic, JOM 60, 50 (2008).

O.L. Harrysson, O. Cansizoglu, D.J. Marcellin-Little, D.R. Cormier, and H.A. West, Mater. Sci. Eng., C 28, 366 (2008).

L.E. Murr, S.M. Gaytan, E. Martinez, F. Medina, and R.B. Wicker, Int. J. Biomater. 2012, 245727 (2012).

S. Gaytan, L.E. Murr, F. Medina, E. Martinez, L. Martinez, and R.B. Wicker, TMS 139th Annual Meeting & Exhibition, vol. 1, 2010, pp. 283–290.

M. Jamshidinia and R. Kovacevic, Surf. Topog. Met. Prop. 3, 014003 (2015).

C.M. Haslauer, J.C. Springer, O.L. Harrysson, E.G. Loboa, N.A. Monteiro-Riviere, and D.J. Marcellin-Little, Med. Eng. Phys. 32, 645 (2010).

H. Tang, S. Lu, W. Jia, G. Yang, and M. Qian, Int. J. Powder Metall. 50, 57 (2014).

W. Xu, M. Brandt, S. Sun, J. Elambasseril, Q. Liu, K. Latham, K. Xia, and M. Qian, Acta Mater. 85, 74 (2015).

D. Greitemeier, C. Dalledonne, F. Syassen, J. Eufinger, and T. Melz, Mater. Sci. Technol. (2015). doi:10.1179/1743284715Y.0000000053.

G.M. Mala and D. Li, Int. J. Heat Fluid Flow 20, 142 (1999).

S.G. Kandlikar, S. Joshi, and S. Tian, Heat Trans. Eng. 24, 4 (2003).

I. Mingareev, T. Bonhoff, A.F. El-Sherif, W. Meiners, I. Kelbassa, T. Biermann, and M. Richardson, J. Laser Appl. 25, 052009 (2013).

K.S. Chan, M. Koike, R.L. Mason, and T. Okabe, Metall. Mater. Trans. A 44, 1010 (2013).

P. Edwards, A. O’Conner, and M. Ramulu, J. Manuf. Sci. Eng. 135, 061016 (2013).

A.T. Beaucamp, Y. Namba, P. Charlton, and A.A. Graziano, ASPE Spring Meeting—Additive Manufacturing, California, 2014.

Y. Bao, J. Newkirk, J. Ruan, T.E. Sparks, and F. Liou, J. Manuf. Proc. 10, 56 (2008).

E. Yasa, J. Deckers, T. Craeghs, M. Badrossamay, and J.P. Kruth, International Solid Freeform Fabrication Symposium, Austin, 2009.

J.W. Dini, Am. Mach. Spec. Rep. 768, 113 (1984).

ASME B46.1-2009: Surface Texture (Roughness, Waviness and Lay).

M.J. Donachie, Titanium: A Technical Guide, 2nd ed. (Materials Park: ASM International, 2000).

S.F. Lamolle, M. Monjo, M. Rubert, H.J. Haugen, S.P. Lyngstadaas, and J.E. Ellingsen, Biomaterials 30, 736 (2009).

M.J. Frank, M.S. Walter, S.P. Lyngstadaas, E. Wintermantel, and H.J. Haugen, Mater. Sci. Eng., C 33, 1282 (2013).

Acknowledgements

Y.Y. Sun acknowledges the support of the China Scholarship Council (CSC) for a CSC scholarship. M. Qian acknowledges the support of the Australian Research Council (ARC) through the Discovery Project Grant of DP150104719. Useful discussions with Prof. H.P. Tang, Director of the State Key Laboratory of Porous Metal Materials, Northwest Institute for Nonferrous Metal Research, Xi’an, China, are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Y.Y., Gulizia, S., Oh, C.H. et al. The Influence of As-Built Surface Conditions on Mechanical Properties of Ti-6Al-4V Additively Manufactured by Selective Electron Beam Melting. JOM 68, 791–798 (2016). https://doi.org/10.1007/s11837-015-1768-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1768-y