Abstract

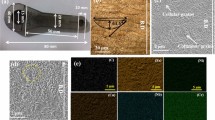

17-4 precipitation hardenable (PH) stainless steel is a useful material when a combination of high strength and good corrosion resistance up to about 315°C is required. In the wrought form, this steel has a fully martensitic structure that can be strengthened by precipitation of fine Cu-rich face-centered cubic phase upon aging. When fabricated via additive manufacturing (AM), specifically laser powder-bed fusion, 17-4 PH steel exhibits a dendritic structure containing a substantial fraction of nearly 50% of retained austenite along with body centered cubic/martensite and fine niobium carbides preferentially aligned along interdendritic boundaries. The effect of post-build thermal processing on the material microstructure is studied in comparison to that of conventionally produced wrought 17-4 PH with the intention of creating a more uniform, fully martensitic microstructure. The recommended stress relief heat treatment currently employed in industry for post-processing of AM 17-4 PH steel is found to have little effect on the as-built dendritic microstructure. It is found that, by implementing the recommended homogenization heat treatment regimen of Aerospace Materials Specification 5355 for CB7Cu-1, a casting alloy analog to 17-4 PH, the dendritic solidification structure is eliminated, resulting in a microstructure containing about 90% martensite with 10% retained austenite.

Similar content being viewed by others

References

ATI technical data sheet, Stainless steel AL 17-4™ precipitation hardening alloy. http://www.specialtysteelsupply.com/brochure/17-4-technical-data.pdf. Accessed 1 Apr 2015.

J.-H. Wu and C.K. Lin, J. Mater. Sci. 38, 965 (2003).

H. Mirzadeh and A. Nazafizadeh, Mater. Chem. Phys. 116, 119 (2009).

M. Murayama, Y. Katayama, and K. Hono, Metall. Mater. Trans. 30A, 345 (1999).

U.K. Viswanathan, S. Banerjee, and R. Krishnan, Mater. Sci. Eng. A 104, 181 (1988).

C.N. Hsiaoa, C.S. Chioub, and J.R. Yanga, Mater. Chem. Phys. 74, 134 (2002).

R.M. Mahamood, E.T. Akinlabi, M. Shukla, and S. Pityana, Lasers Eng. 27, 161 (2014).

L.E. Murr, Additive Manuf. 5, 40 (2015).

W.E. Luecke and J.A. Slotwinski, J. Res. Natl. Inst. Stan. Technol. 119, 398 (2014).

I. Tolosa, F. Garciandía, F. Zubiri, F. Zapirain, and A. Esnaola, Int. J. Adv. Manuf. Technol. 51, 639 (2010).

M. Averyanova, P. Bertrand, and B. Verquin, Annals of DAAAM for 2010 and Proceedings of the 21st International DAAAM Symposium, ed. B. Katalinic (Austria: DAAAM International, 2010), 21(1), ISSN 1726-9679, ISBN 978-3-901509-73-5.

L.E. Murr, E. Martinez, J. Hernandez, S. Collins, K.N. Amato, S.M. Gaytan, and P.W. Shindo, J. Mater. Res. Technol. 1, 167 (2012).

L.E. Murr, E. Martinez, K.N. Amato, S.M. Gaytan, J. Hernandez, D.A. Ramirez, P.W. Shindo, F. Medina, and R.B. Wicker, J. Mater. Res. Technol. 1, 42 (2012).

H. Khalid Rafi, D. Pal, N. Patil, T.L. Starr, and B.E. Stucker, J. Mater. Eng. Perf. 23, 4421 (2014).

T.L. Starr, H. Khalid Rafi, B.E. Stucker, and C.M. Scherzer, Proceedings of the 23rd Annual International Solid Freeform Fabrication Symposium (University of Texas, Austin, 2012), pp. 439–446.

Mention of commercial products is provided for completeness and does not imply endorsement by NIST, nor does it imply that such products are necessarily the best available for the purpose.

D.D. Gu, W. Meiners, K. Wissenbach, and R. Poprawe, Int. Mater. Rev. 57, 133 (2012).

EOS Material data sheet, EOS stainless steel GP1 for EOSINT M 270. http://www.eos.info/material-m. Accessed 23 Oct 2014.

AK Steel product data bulletin, 17-4 PH stainless steel. http://www.aksteel.com/pdf/markets_products/stainless/precipitation/17-4_PH_Data_Bulletin.pdf. Accessed 1 Apr 2015.

Aerospace material specification, Steel, corrosion resistant, investment castings 16Cr-4.1Ni-0.28Cb-3.2Cu-homogenization and solution heat treated or homogenization, solution, and precipitation heat treated. http://standards.sae.org/ams5355/. Accessed 18 May 2015.

Thermo-Calc 3.0, Themo-Calc Software AB, Stockholm, Sweden, 2013.

TCFE6 Fe-based alloy database, Themo-Calc Software AB, Stockholm, 2009.

T. Vilaro, C. Colin, and J.D. Bartout, Metall. Mater. Trans. A 42, 3190 (2011).

Q. Chen and B. Sundman, Mater. Trans. 43, 551 (2002).

W. Wu, L.Y. Hwu, D.Y. Lin, and J.L. Lee, Scripta Mater. 42, 1071 (2000).

R. Colaco and R. Vilar, Mater. Sci. Eng. A 385, 123 (2004).

K. Kempen, E. Yasa, L. Thijs, J.-P. Kruth, and J. Van Humbeeck, Phys. Procedia 12, 255 (2011).

R. Colaco and R. Vilar, J. Mater. Sci. Lett. 17, 563 (1998).

D. Das, A.K. Dutta, and K.K. Ray, Mater. Sci. Eng. A 527, 2182 (2010).

Acknowledgement

The authors would like to thank the NIST Engineering Laboratory for building the additively manufactured 17-4 steel used in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheruvathur, S., Lass, E.A. & Campbell, C.E. Additive Manufacturing of 17-4 PH Stainless Steel: Post-processing Heat Treatment to Achieve Uniform Reproducible Microstructure. JOM 68, 930–942 (2016). https://doi.org/10.1007/s11837-015-1754-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1754-4