Abstract

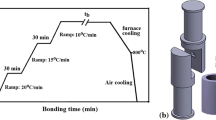

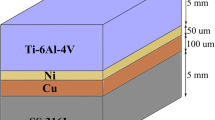

Partial transient liquid phase (PTLP) bonding of TiC cermet to 06Cr19Ni10 stainless steel was carried out. Impulse pressuring was used to reduce the bonding time, and a Ti/Cu/Nb interlayer was employed to alleviate the detrimental effect of interfacial reaction products on the bonding strength. Successful bonding was achieved at 885 °C under a pulsed pressure of 2–10 MPa within durations in the range of 2–8 min, which was notably shortened in comparison with conventional PTLP bonding. Microstructure characterization revealed the σ phase with a limit solubility of Nb, a sequence of Ti—Cu intermetallic phases and solid solutions of Ni and Cu in α+β Ti in the reaction zone. The maximum shear strength of 106.7 MPa was obtained when the joint was bonded for 5 min, indicating that a robust metallurgical bonding was achieved. Upon shear loading, the joints fractured along the Ti—Cu intermetallics interface and spread to the interior of TiC cermet in a brittle cleavage manner.

摘要

部分瞬间液相焊接(PTLP)综合了钎焊和固相扩散连接的优点,且对连接母材表面粗糙度比 传统固相连接相对较低,因此在陶瓷和金属异种材料连接方向上具有较大的优势。采用Ti—Cu—Nb 金 属中间层,对TiC 金属陶瓷与06Cr19Ni10 不锈钢进行PTLP 连接试验。通过SEM、EDS、XRD 和拉 伸试验等方法,研究了活性元素中间层、工艺参数对TiC/TiCuNb/06Cr19Ni10 瞬间液相焊接头性能与 界面微观结构的影响规律。结果表明,在连接温度885 °C、脉冲压力2~10 MPa 的工艺条件下保温5 min 时接头剪切强度达到最大值(~106.7 MPa)。微观组织表征发现,在TiC 金属陶瓷一侧,Ti—Cu 层在高 于共晶点的连接温度时发生熔化,与TiC 金属陶瓷、核心金属层Nb 产生界面反应;而在304SS 侧, Nb 与304SS 进行固相扩散, 形成具有固相扩散特征的连接结构, 连接后界面形成 06Cr19Ni10/σ/Nb/CuTi/CuTi2/α+βTi/TiC 过渡结构。连接接头的裂纹沿着Ti—Cu 金属化合物层向TiC 陶 瓷母材扩展,呈脆性解理断裂特征。

Similar content being viewed by others

References

LIU N, XU Y D, LI H. Effect of nano-micro TiN addition on the microstructure and mechanical properties of TiC based cermets [J]. J Eur Ceram Soc, 2002, 22(13): 2409–2414.

SUN K N, YIN Y S, LI A M. Intermetallics/ceramic matrix composite [M]. Beijing: China Machine Press, 2002. (in Chinese)

TRAVESSA D, FERRANTE M, DEN O G. Diffusion bonding of aluminium oxide to stainless steel using stress relief interlayers [J]. Mater Sci Eng A, 2002, 337(1): 287–296.

SHEN X Q, LI Y J, PUTCHKOV U A. Finite-element analysis of residual stresses in Al2O3–TiC/W18Cr4V diffusion bonded joints [J]. Comp Mater Sci, 2009, 45(2): 407–410.

YE D M, XIONG W H. Vacuum brazing of Ti(C, N) based cermets to 45 Steel [J]. Rare Metal Mat Eng, 2008, 37(7): 1281–1284.

PIERSON H O. Handbook of refractory carbides & nitrides: Properties, characteristics, processing and apps [M]. William Andrew, 1996.

GOMEZ-DE-SALAZAR J M, BARRENA M I. Dissimilar fusion welding of AA7020/MMC reinforced with Al2O3 particles, microstructure and mechanical properties [J]. Mater Sci Eng A, 2003, 352(1): 162–168.

BARRENA M I, GOMEZ-DE-SALAZAR J M, MATESANZ L. Ni–Cu alloy for diffusion bonding cermet/steel in air [J]. Mater Lett, 2009, 63(24): 2142–2145.

LI Z R, FENG J C, CAO J. Vacuum diffusion bonding of TiB2 cermet to TiAl based alloys [J]. Mater Sci Tech-Lond, 2004, 20(12): 1666–1668.

HUANG W Q, LI Y, WANG J. Microstructure and fracture of TiC-Al2O3/W18Cr4V diffusion bonded joint [J]. Kovove Mater, 2010, 48: 227–231.

CHEN Z, CAO M S, ZHAO Q Z. Interfacial microstructure and strength of partial transient liquid-phase bonding of silicon nitride with Ti/Ni multi-interlayer [J]. Mater Sci Eng A, 2004, 380(1): 394–401.

ZHENG C, LOU H, FEI Z. Partial transient liquid-phase bonding of Si3N4 with Ti/Cu/Ni multi-interlayers [J]. J Mater Sci Lett, 1997, 16(24): 2026–2028.

WANG G, LANNUTTI J J. Chemical thermodynamics as a predictive tool in the reactive metal brazing of ceramics [J]. Metall Mater Trans A, 1995, 26(6): 1499–1505.

MASSALSKI T B, OKAMOTO H, SUBRAMANIAN P R. Binary alloy phase diagrams [M]. Materials Park, OH: ASM International, 1990.

YANG M, ZOU Z D, SONG S L. Effect of interlayer thickness on strength and fracture of Si3N4 and Inconel600 joint [J]. Key Eng Mater, 2005, 297: 2435–2440.

MARKS R A, SUGAR J D, GLAESER A M. Ceramic joining IV. Effects of processing conditions on the properties of alumina joined via Cu/Nb/Cu interlayers [J]. J Mater Sci, 2001, 36(23): 5609–5624.

SHACKELFORD J F, ALEXANDER W. CRC materials science and engineering handbook [M]. CRC Press, 2010.

HAN J, SHENG G M, ZHOU X L. Pulse pressuring diffusion bonding of Ti alloy/austenite stainless steel processed by surface self-nanocrystallization [J]. ISIJ Int, 2009, 49(1): 86–91.

SUN X J, GU J L, BAI B Z, CHEN N P. Fabrication of submicron grained titanium alloy by compressive deformation [J]. Acta Metall Sin-Engl, 2009, 13(2): 638–644.

LIU G M, ZOU G S, WU A P. Improvements of the Si3N4 brazed joints with intermetallics [J]. Mater Sci Eng A, 2006, 415(1): 213–218.

XU H, DU Y, HUANG B. Phase equilibria of the Cu–Nb–Ti system at 850 °C [J]. J Alloy Compd, 2005, 399(1): 92–95.

KUNDU S, CHATTERJEE S. Characterization of diffusion bonded joint between titanium and 304 stainless steel using a Ni interlayer [J]. Mater Charact, 2008, 59(5): 631–637.

ZDANIEWSKI W A, CONWAY J C, KIRCHNER H P. Effect of joint thickness and residual stresses on the properties of ceramic adhesive joints: II, Experimental results [J]. J Am Ceram Soc, 1987, 70(2): 110–118.

BLUGAN G, KUEBLER J, BISSIG V. Brazing of silicon nitride ceramic composite to steel using SiC-particlereinforced active brazing alloy [J]. Ceram Int, 2007, 33(6): 1033–1039.

SINGH M, MARTINEZ F J, ASTHANA R. Interfacial characterization of silicon nitride/silicon nitride joints brazed using Cu-base active metal interlayers [J]. Ceram Int, 2012, 38(4): 2793–2802.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51421001) supported by the National Natural Science Foundation of China; Projects(106112015CDJXZ138803, 106112015CDJXY130003) supported by the Fundamental Research Funds for the Central Universities, China

Rights and permissions

About this article

Cite this article

Huang, L., Sheng, Gm., Li, J. et al. Partial transient-liquid-phase bonding of TiC cermet to stainless steel using impulse pressuring with Ti/Cu/Nb interlayer. J. Cent. South Univ. 25, 1025–1032 (2018). https://doi.org/10.1007/s11771-018-3802-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3802-z