Abstract

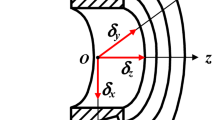

A dynamic model of a helical gear rotor system is proposed. Firstly, a generally distributed dynamic model of a helical gear pair with tooth profile errors is developed. The gear mesh is represented by a pair of cylinders connected by a series of springs and the stiffness of each spring is equal to the effective mesh stiffness. Combining the gear dynamic model with the rotor-bearing system model, the gear-rotor-bearing dynamic model is developed. Then three cases are presented to analyze the dynamic responses of gear systems. The results reveal that the gear dynamic model is effective and advanced for general gear systems, narrow-faced gear, wide-faced gear and gear with tooth profile errors. Finally, the responses of an example helical gear system are also studied to demonstrate the influence of the lead crown reliefs and misalignments. The results show that both of the lead crown relief and misalignment soften the gear mesh stiffness and the responses of the gear system increase with the increasing lead crown reliefs and misalignments.

摘要

本文研究了斜齿轮转子系统动力学模型。 首先, 将斜齿轮啮合等效为沿齿宽方向上分布的一系列并联弹簧相连的圆柱, 其中弹簧的刚度为齿轮等效啮合刚度, 建立误差齿廓斜齿轮分布式动力学模型。 进一步结合转子–轴承动力学模型, 建立齿轮–转子–轴承系统动力学模型。 然后, 通过 3 个算例分析了齿轮系统的动力学响应, 结果显示, 对于窄齿面齿轮、 宽齿面齿轮、 修形齿廓齿轮, 本文的动力学模型均是有效的。 最后, 分析了齿向修形和齿轮不对中对齿轮系统动力学响应的影响, 结果表明, 齿向修形和齿轮不对中使得齿轮的刚度变小、 齿轮系统的振动响应变大。

Similar content being viewed by others

Change history

18 April 2018

The first author’s affiliation was no longer in use in the original version of the article and it should be replaced as follows: School of Mechano-Electronic Engineering, Xidian University, Xi’an 710071, China.

References

PALERMO A, MUNDO D, HADJIT R, DESMET W. Multibody element for spur and helical gear meshing based on detailed three-dimensional contact calculations [J]. Mechanism and Machine Theory, 2013, 62: 13–30. DOI: 10.1016/j.mechmachtheory.2012.11.006.

VELEX P, AJMI M. On the modelling of excitations in geared systems by transmission errors [J]. Journal of Sound and Vibration, 2006, 290(3): 882–909. DOI: 10.1016/j.jsv.2005. 04.033.

MOHAMAD E N, KOMORI M, MURAKAMI H, KUBO A, FANG S. Analysis of general characteristics of transmission error of gears with convex modification of tooth flank form considering elastic deformation under load [J]. Journal of Mechanical Design, 2009, 131(6): 1–9. DOI: 10.1115/ 1.3116261.

VELEX P, AJMI M. Dynamic tooth loads and quasi-static transmission errors in helical gears—Approximate dynamic factor formulae [J]. Mechanism and Machine Theory, 2007, 42(11): 1512–1526. DOI: 10.1016/j.mechmachtheory.2006. 12.009.

VELEX P, BRUYERE J, HOUSER D R. Some analytical results on transmission errors in narrow-faced spur and helical gears: influence of profile modifications [J]. Journal of Mechanical Design, 2011, 133, 3: 031010. DOI: 10.1115/ 1.4003578.

MUNRO R. A review of the theory and measurement of gear transmission error [J]. Proceedings of the First IMechE Conference on Gearbox Noise and Vibration (Paper c404/032). 1990: 3–10.

MUNRO R, PALMER D, MORRISH L. An experimental method to measure gear tooth stiffness throughout and beyond the path of contact [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2001, 215(7): 793–803.

WANG Qi-bin, ZHAO Bo, FU Yang, KONG Xian-guang, MA Hui. An improved time-varying mesh stiffness model for helical gear pairs considering axial mesh force component [J]. Mechanical Systems and Signal Processing, 2018. https://doi.org/ 10.1016/j.ymssp.2018.01.012.

MATSUHISA H, MIYAJI Y, SATO S. Parametrically excited vibration with external constant load and damping [J]. Memoirs of the Faculty of Engineering, Kyoto Univ, 1982, 44: 158–167.

WEBER C. The deformation of loaded gears and the effect on their load-carrying capacity. Part 3 [M]. Dept. of Scientific and Industrial Research, Sponsored Research, Germany, 1949.

YANG D C H, LIN J. Hertzian damping, tooth friction and bending elasticity in gear impact dynamics [J]. Journal of Mechanisms, Transmissions, and Automation in Design, 1987, 109(2): 189–196.

CHEN Zai-gang, SHAO Yi-min. Dynamic simulation of spur gear with tooth root crack propagating along tooth width and crack depth [J]. Engineering Failure Analysis, 2011, 18(8): 2149–2164. http://dx.doi.org/10.1016/j.engfailanal.2011.07.006.

CHEN Zai-gang, SHAO Yi-min. Mesh stiffness calculation of a spur gear pair with tooth profile modification and tooth root crack [J]. Mechanism and Machine Theory, 2013, 62: 63–74. DOI: http://dx.doi.org/10.1016/j.mechmachtheory. 2012.10.012.

MA Hui, SONG Rong-ze, PANG Xu, ZENG Jin, WEN Bang-chun. Time-varying mesh stiffness calculation of cracked spur gears [J]. Engineering Failure Analysis, 2014, 44: 179–194. DOI: 10.1016/j.engfailanal.2014.05.018.

MA Hui, PANG Xu, FENG Ran-jiao, HE Wang-peng, HE Zhen-jia. Improved time-varying mesh stiffness model of cracked spur gears [J]. Engineering Failure Analysis, 2015, 55: 271–287. DOI: 10.1016/j.engfailanal.2015.06.007.

WAN Zhi-guo, CAO Hong-rui, ZI Yan-yang, HE Wang-peng, HE Zheng-jia. An improved time-varying mesh stiffness algorithm and dynamic modeling of gear-rotor system with tooth root crack [J]. Engineering Failure Analysis, 2014, 42: 157–177. DOI: 10.1016/j.engfailanal.2014.04.005.

LI S. Effects of machining errors, assembly errors and tooth modifications on loading capacity, load-sharing ratio and transmission error of a pair of spur gears [J]. Mechanism and Machine Theory, 2007, 42(6): 698–726. DOI: http://dx.doi. org/10.1016/j.mechmachtheory.2006.06.002.

LI S. Effect of addendum on contact strength, bending strength and basic performance parameters of a pair of spur gears [J]. Mechanism and Machine Theory, 2008, 43(12): 1557–1584.

LI S. Effects of misalignment error, tooth modifications and transmitted torque on tooth engagements of a pair of spur gears [J]. Mechanism and Machine Theory, 2015, 83: 125–136. DOI: http://dx.doi.org/10.1016/j.mechmachtheory. 2014.09.011.

WEI Jing, SUN Wei, WANG Li-cun. Effects of flank deviation on load distributions for helical gear [J]. Journal of Mechanical Science and Technology, 2011, 25(7): 1781–1789. DOI: 10.1007/s12206-011-0416-x.

WANG Qi-bin, ZHANG Yi-min. A model for analyzing stiffness and stress in a helical gear pair with tooth profile errors [J]. Journal of Vibration and Control, 2017, 23(2): 272–289. DOI: 10.1177/1077546315576828.

VELEX P. On the modelling of spur and helical gear dynamic behaviour [M]. ArXiv preprint, 2012, arXiv:1204.2636.

ANDERSSON A, VEDMAR L. A dynamic model to determine vibrations in involute helical gears [J]. Journal of Sound and Vibration, 2003, 260(2): 195–212. DOI: 10.1016/s0022-460x(02)00920-3.

IIDA H, TAMURA A, KIKUCH K, AGATA H. Coupled torsional-flexural vibration of a shaft in a geared system of rotros-1 [J]. Bulletin of the JSME, 1980, 23(186): 2111–2117.

HUANG Guan-hui, XU Si-si, ZHANG Wei-hua, YANG Cai-jin. Super-harmonic resonance of gear transmission system under stick-slip vibration in high-speed train [J]. Journal of Central South University, 2017, 24(3): 726–735. DOI: 10.1007/s11771-017-3474-0.

CHOI S T, MAU S Y. Dynamic analysis of geared rotor-bearing systems by the transfer matrix method [J]. Journal of Mechanical Design, 2001, 123(4): 562–568.

LEE A S, HA J W, CHOI D H. Coupled lateral and torsional vibration characteristics of a speed increasing geared rotor-bearing system [J]. Journal of Sound and Vibration, 2003, 263(4): 725–42. DOI: 10.1016/s0022-460x(02)01103-3.

CUI Ya-hui, LIU Zhan-sheng, WANG Yong-liang, YE Jian-huai. Nonlinear dynamic of a geared rotor system with nonlinear oil film force and nonlinear mesh force [J]. Journal of Vibration and Acoustics, 2012, 134, 4: 041001.

MA Hui, FENG Ran-jiao, PANG Xu, SONG Rong-zen, WEN Bang-chun. Effects of tooth crack on vibration responses of a profile shifted gear rotor system [J]. Journal of Mechanical Science and Technology, 2015, 29(10): 4093–4104. DOI: 10.1007/s12206-015-0903–6.

KAHRAMAN A. Effect of axial vibrations on the dynamics of a helical gear pair [J]. Journal of Vibration and Acoustics, 1993, 115(1): 33–39.

BLANKENSHIP G W, SINGH R. Dynamic force transmissibility in helical gear pairs [J]. Mechanism and Machine Theory, 1995, 30(3): 323–339. DOI: 10.1016/0094-114x(94)00048-p.

BLANKENSHIP G W, SINGH R. A new gear mesh interface dynamic model to predict multi-dimensional force coupling and excitation [J]. Mechanism and Machine Theory, 1995, 30(1): 43–57. DOI: 10.1016/0094-114x(94)00018-g.

KUBUR M, KAHRAMAN A, ZINI D M, KIENILE K. Dynamic analysis of a multi-shaft helical gear transmission by finite elements: Model and experiment [J]. Journal of Vibration and Acoustics, Transactions of the ASME, 2004, 126(3): 398–406. DOI: 10.1115/1.1760561.

ZHANG Yi-min, WANG Qi-bin, MA Hui, HUANG Jin, ZHAO Chun-yu. Dynamic analysis of three-dimensional helical geared rotor system with geometric eccentricity [J]. Journal of Mechanical Science and Technology, 2013, 27(11): 3231–3242. DOI: 10.1007/s12206-013-0846-8.

NISHINO T. Vibration analysis of the helical gear system using the integrated excitation model [J]. Journal of Advanced Mechanical Design Systems and Manufacturing, 2007, 1(4): 541–552. DOI: 10.1299/jamdsm.1.541.

NISHINO T. Integrated excitation models of the helical gear system [J]. ASME 2007 International Design Engineering Technical Conference and Computers and Information in Engineering Conference. American Society of Mechanical Engineers, 2007: 477–486.

ERITENEL T, PARKER R G. An investigation of tooth mesh nonlinearity and partial contact loss in gear pairs using a lumped-parameter model [J]. Mechanism and Machine Theory, 2012, 56: 28–51. DOI: 10.1016/j.mechmachtheory. 2012.05.002.

ERITENEL T, PARKER R G. Three-dimensional nonlinear vibration of gear pairs [J]. Journal of Sound and Vibration, 2012, 331(15): 3628–3648. DOI: 10.1016/j.jsv.2012.03.019.

VELEX P, MAATAR M. A mathematical model for analyzing the influence of shape deviations and mounting errors on gear dynamic behaviour [J]. Journal of Sound and Vibration, 1996, 191(5): 629–660. DOI: 10.1006/jsvi.1996. 0148.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(51605361, 51505357) supported by the National Natural Science Foundation of China; Projects(XJS16041, JB160411) supported by the Fundamental Research Funds for the Central Universities, China

Rights and permissions

About this article

Cite this article

Wang, Qb., Ma, Hb., Kong, Xg. et al. A distributed dynamic mesh model of a helical gear pair with tooth profile errors. J. Cent. South Univ. 25, 287–303 (2018). https://doi.org/10.1007/s11771-018-3737-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3737-4