Abstract

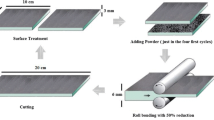

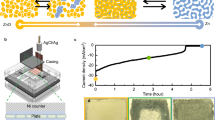

A new type of lead-based porous anode in zinc electrowinning was prepared by negative pressure infiltration. The anodic polarization potential and corrosion rate were studied and compared with those of traditional flat anodes (Pb-0.8%Ag) used in industry. The anode corrosion rate was determined by anode actual current density and microstructure. The results show that the anodic oxygen evolution potential decreases first and then increases with the decrease of pore diameter. The anodic potential decreases to the lowest value of 1.729 V at the pore diameter of 1.25–1.60 mm. The porous anode can decrease its actual current density and thus decrease the anodic corrosion rate. When the pore diameter is 1.60–2.00 mm, the anodic relative corrosion rate reaches the lowest value of 52.1%.

Similar content being viewed by others

References

PETROVA M, STEFANOV Y, NONCHEVA Z, DOBREV T, RASHKOV S. Electrochemical behaviour of lead alloys as anodes in zinc electrowinning [J]. British Corrosion Journal, 1999, 34(3): 198–200.

STEFANOV Y, DOBREV T. Potentiodynamic and electron-microscopy investigations of lead-cobalt alloy coated lead composite anodes for zinc electrowinning [J]. Transactions of the Institute of Metal Finishing, 2005, 83(6): 296–299.

IVANOV I, STEFANOV Y, NONCHEVA Z, PETROVA M, DOBREV T, MIRKOVA L, VERMEERSCH R, DEMAEREL J P. Insoluble anodes used in hydrometallurgy (Part I): Corrosion resistance of lead and lead alloy anodes [J]. Hydrometallurgy, 2000, 57(2): 109–124.

RASHKOV S, DOBREV T, NONCHEVA Z, STEFANOV Y, RASHKOVA B, PETROVA M. Lead-cobalt anodes for electrowinning of zinc from sulphate electrolytes [J]. Hydrometallurgy, 1999, 52(3): 223–230.

LI Bao-song, LIN An, GAN Fu-xing. Preparation and electro-catalytic properties of Ti/IrO2-Ta2O5 anodes for oxygen evolution [J]. Trans Nonferrous Met Soc China, 2006, 16(5): 1193–1199.

HU Ji-ming, ZHANG Jian-qing, CAO Chu-nan. Oxygen evolution reaction on IrO2-based DSA type electrodes: Kinetics analysis of Tafel lines and EIS [J]. International Journal of Hydrogen Energy, 2004, 29(8): 791–797.

STEFANOV Y, DOBREV T. Developing and studying the properties of Pb-TiO2 alloy coated lead composite anodes for zinc electrowinning [J]. Transactions of the Institute of Metal Finishing, 2005, 83(6): 291–295.

FELDER A, PRENGAMAN R D. Lead alloys for permanent anode in the nonferrous metals industry [J]. JOM, 2006, 58(10): 28–31.

PENG Rong-qiu, REN Hong-jiu, ZHANG Xun-peng. Metallurgy of lead and zinc [M]. Beijing: Science Press, 2003: 413. (in Chinese)

IRRETIER A, BANHART J. Lead and lead alloy foams [J]. Acta Materialia, 2005, 53(18): 4903–4917.

ZHOU Xiang-yang, LI Shan-ni, LI Jie, LIU Ye-xiang. Preparation of precursor for stainless steel foam [J]. Journal of Central South University of Technology, 2008, 15(2): 209–213.

DAI Chang-song, ZHANG Bin, WANG Dian-long, YI Ting-feng, HU Xin-guo. Preparation and performance of lead foam grid for negative electrode of VRLA battery [J]. Materials Chemistry and Physics, 2006, 99(2/3): 431–436.

ZHANG Yong. Low-pressure infiltrating technology of foam aluminum and its familiar defects [J]. Foundry Technology, 2004, 8(8): 596–599. (in Chinese)

RUSSELL G, JEAN-FRANCOIS D, ARIANE M, LUC S, ANDREAS M. The effect of preform processing on replicated aluminium foam structure and mechanical properties [J]. Scripta Materialia, 2006, 54(12): 2069–2073.

BANHART J. Manufacture, characterization and application of cellular metals and metal foams [J]. Progress in Materials Science, 2001, 46(6): 559–632.

BERCHEM K, MOHR U, BLECK W. Controlling the degree of pore opening of metal sponges, prepared by the infiltration preparation method [J]. Mater Sci Eng A, 2002, A323(1/2): 52–57.

MA Li-qun, SONG Zhen-lun, HE De-ping. Cellular structure controllable aluminium foams produced by high pressure infiltration process [J]. Scripta Materialia, 1999, 41(7): 785–789.

PALMER R A, GAO K, DOAN T M, GREEN L, CAVALLARO G. Pressure infiltrated syntactic foams — Process development and mechanical properties [J]. Mater Sci Eng A, 2007, A464(1/2): 85–92.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2007SK2009) supported by the Science and Technology Research Project of Hunan Province, China

Rights and permissions

About this article

Cite this article

Zhong, Sp., Lai, Yq., Jiang, Lx. et al. Fabrication and anodic polarization behavior of lead-based porous anodes in zinc electrowinning. J. Cent. South Univ. Technol. 15, 757–762 (2008). https://doi.org/10.1007/s11771-008-0140-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-008-0140-6