Abstract

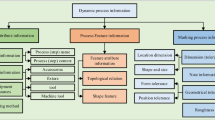

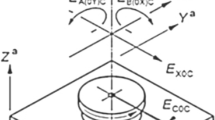

The manufacturing process of turn-milling offers high productivity, high geometrical flexibility, safe chip breaking and machining of twist-free surfaces. However, the achievable accuracies and surface qualities do not allow the substitution of finish grinding processes. Thereby the dynamic profile of process forces is one of the main disturbance values. This paper presents a new process model of orthogonal eccentric turn-milling without axial feed. Thus the focus lies on the analysis of the process forces and their dynamic behavior caused by the changing chip cross section area on the face cutting edge. The developed model considers single and multiple cutting edge tools and has a geometrical-empirical character. This model describes the process kinematics and the error inducing process forces in orthogonal turn-milling. Their dynamic profile can be analyzed and minimized using multiple cutting edge tools and customized pre-machining of the workpiece surface topography with the goal of creating a robust process to substitute the finish grinding process in high precision applications. Such applications include, for example, the main and pin bearing seats of crank shafts used in the automotive and truck industry or even for large ship engines. The key feature is to minimize the form deviation of the cylindricity, which results from straightness and roundness of the workpiece surface to below 10 µm for crank shafts used in the truck industry. The model is adjusted and verified by experimental tests.

Similar content being viewed by others

References

König W, Wand Th (1984) Exzentrisches Drehfräsen. Industrie Anzeiger, Band 106, Heft 30, S34–36 (Aachen)

Wedeniwski H (1984) Rundheitsfehler beim Stirndrehfräsen. Werkstatt und Betrieb Band 117/1:41–42 (Köln)

Sorge K-P (1984) Die Technologie des Drehfräsens. Carl Hanser Verlag, München/Wien, TH Darmstadt

Sorge K-P (1984) Komplettbearbeiten durch Drehfräsen. Werkstatt und Betrieb 117/1:37–39 (Köln)

Schulz H, Lehmann Th (1991) Spanungsgeometrie beim orthogonalen Drehfräsen. Technica 40/19: 16–24 (Zürich)

Sahm D (1996) Oberflächenbeschaffenheit und Produktivität beim orthogonalen Drehfräsen. Dissertation, Shaker Verlag Aachen, TH Darmstadt

Kopac J, Pogacnik M (1997) Theory and practice of achieving quality surface in turn-milling. Int J Mach Tools Manuf 37(5):709–715 (Ljubljana, Slovenia)

Seco Tools (1998) Drehfräsen spart Zeit. Seco Berichte und Informationen aus aller Welt Nr. 2; Sweden

Kara ME, Budak E (2015) Optimization of turn-milling processes. Procedia CIRP 33:476–483 (Istanbul, Turkey)

Karaguzel U, Uysal E, Budak E, Bakkal M (2016) Effects of tool axis offset in turn-milling process. J Mater Process Technol 231:239–247 (Istanbul, Turkey)

Karaguzel U, Budak E, Bakkal M, Wertheim R (2016) Improving performance of turn-milling by controlling forces and thermally induced tool-center point (TCP) displacement. Procedia CIRP 40:481–485 (Istanbul, Turkey)

Riemer O (2001) Trennmechanismen und Oberflächenfeingestaltung bei der Mikrozerspanung kristalliner und amorpher Werkstoffe. Dissertation, Universität Bremen

Tabellenbuch für Zerspantechnik (2015) 1. Aufl. Verlag Europa Lehrmittel

Degner W, Lutze H, Smejkal E (2009) Spanende Formung—Theorie—Berechnung—Richtwerte. 16. Aufl. Carl Hanser Verlag

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hertel, M., Dix, M. & Putz, M. Analytic model of process forces for orthogonal turn-milling. Prod. Eng. Res. Devel. 12, 491–500 (2018). https://doi.org/10.1007/s11740-018-0828-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-018-0828-x