Abstract

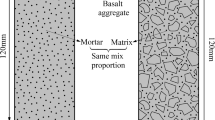

A push-out test program was designed and conducted to study the meso-scale behavior of mortar-aggregate interface for concrete after elevated temperatures ranging from 20°C to 600°C with the concept of modeled concrete (MC) and modeled recycled aggregate concrete (MRAC). The MCs and MRACs were designed with different strength grade of mortar and were exposed to different elevated temperatures. Following that the specimens were cooled to room temperature and push-out tests were conducted. Failure process and mechanical behaviors were analyzed based on failure modes, residual load-displacement curves, residual peak loads and peak displacements. It is found that failure modes significantly depended on specimen type, the elevated temperature and the strength grade of mortar. For MC, major cracks started to propagate along the initial cracks caused by elevated temperatures at about 80% of residual peak load. For MRAC, the cracks appeared at a lower level of load with the increasing elevated temperatures. The cracks connected with each other, formed a failure face and the specimens were split into several parts suddenly when reaching the residual peak load. Residual load-displacement curves of different specimens had similarities in shape. Besides, effect of temperatures and strength grade of mortar on residual peak load and peak displacement were analyzed. For MC and MRAC with higher strength of new hardened mortar, the residual peak load kept constant when the temperature is lower than 400°C and dropped by 43.5% on average at 600°C. For MRAC with lower strength of new hardened mortar, the residual peak load began to reduce when the temperatures exceeded 200°C and reduced by 27.4% and 60.8% respectively at 400°C and 600°C. The properties of recycled aggregate concrete (RAC) may be more sensitive to elevated temperatures than those of natural aggregate concrete (NAC) due to the fact that the interfacial properties of RAC are lower than those of NAC, and are deteriorated at lower temperatures.

Similar content being viewed by others

References

Chang Y F, Chen Y H, Sheu M S, Yao G C. Residual stress-strain relationship for concrete after exposure to high temperatures. Cement and Concrete Research, 2006, 36(10): 1999–2005

Rostasy F S, Hinrichsmeyer K. Structural alterations in concrete due to thermal and mechanical stresses. In: Proceedings of the International Conference on Materials Science to Construction Materials Engineering. Cersailles, 1987

Sideny M, Young J F, Darwin D. Concrete. Translated by Wu K, Zhang X, Yao W, et al. Beijing: Chemical Industry Press, 2005

Xiao J Z, Ding T. Research on recycled concrete and its utilization in building structure in China. Frontiers of Structural and Civil Engineering, 2013, 7(3): 215–226

Mehta P K, Monteiro P J M. Concrete structure properties and materials. 2nd ed. Englewood Cliffs: prentice Hall, 1993

Rao G A, Prasad R. Influence of the roughness of aggregate surface on the interface bond strength. Cement and Concrete Research, 2002, 32(2): 253–257

Akcaoglu T, Tokyay M, Celik T. Effect of coarse aggregate size and matrix quality on ITZ and failure behavior of concrete under uniaxial compression. Cement and Concrete Composites, 2004, 26(6): 633–638

Guinea G V, El-sayed K, Rocco C G, Elices M, Planas J. The effect of the bond between the matrix and the aggregates on the cracking mechanism and fracture parameters of concrete. Cement and Concrete Research, 2002, 32(12): 1961–1970

Poon C S, Shui Z H, Lam L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Construction & Building Materials, 2004, 18(6): 461–468

Xiao J Z, Li W G, Sun Z H, Lange D A, Shah S P. Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation. Cement and Concrete Composites, 2013, 37: 276–292

Diamond S, Huang J D. The ITZ in concrete–a different view based on image analysis and SEM observations. Cement and Concrete Composites, 2001, 23(2-3): 179–188

Xotta G, Mazzucco G, Salomoni V A, Majorana C E, Willam K J. Composite behavior of concrete materials under high temperatures. International Journal of Solids and Structures, 2015, 64: 86–99

Shah S P, Winter G. Inelastic behavior and fracture of concrete. ACI Special Publications, 1968, 20: 5–28

Buyukozturk O, Nilson A H, Slate F O. Stress-strain response and fracture of concrete in biaxial loading. ACI Journal Proceedings, 1971, 68: 590–599

Xiao J Z, LiWG, Sun Z H, Shah S P. Crack propagation in recycled aggregate concrete under uniaxial compressive loading. ACI Materials Journal, 2012, 109(4): 451–461

Xiao J Z, LiWG, Corr D J, Shah S P. Effects of interfacial transition zones on the stress-strain behavior of modeled recycled aggregate concrete. Cement and Concrete Research, 2013, 52(10): 82–99

Caliskan S. Aggregate/mortar interface: Influence of silica fume at the micro-and macro-level. Cement and Concrete Composites, 2003, 25(4): 557–564

Zhang Y F, Liu H, Qi L. Simulation of fiver pushing-out test. J Wuhan Univ Technol, 2009, 6(6): 965–969

Park R, Paulay T. Reinforced concrete structures. New York: John Wiley &Son Inc, 1975

Chan Y N, Peng G F, Anson M. Residual strength and pore structure of high-strength concrete and normal strength concrete after exposure to high temperatures. Cement and Concrete Composites, 1999, 21(1): 23–27

Ma Q M, Guo R X, Zhao Z M, Lin Z, He K. Mechanical properties of concrete at high temperature–A review. Construction & Building Materials, 2015, 93: 371–383

Piasta J, Sawicz Z, Rudzinski L. Changes in the structure of hardened cement paste due to high temperature. Materiales de Construcciin, 1984, 17(4): 291–296

Peng G F, Huang Z S. Change in microstructure of hardened cement paste subjected to elevated temperatures. Construction & Building Materials, 2008, 22(4): 593–599

Ibrahim R K, Hamid R, Taha M R. Fire resistance of high-volume fly ash mortars with nanosilica addition. Construction & Building Materials, 2012, 36: 779–786

Taylor H F W. Cement chemistry. 2nd ed. Thomas Telford, 1997

Lin W M, Lin T D, Powers-Couche L J. Microstructures of firedamaged concrete. ACI Materials Journal, 1996, 93(3): 199–205

Acknowledgements

The authors would like to gratefully acknowledge the research grants from the Chinese National 973 Plan (Grant No. 2012CB719703).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W., Xiao, J., Xu, S. et al. Experimental study on behavior of mortar-aggregate interface after elevated temperatures. Front. Struct. Civ. Eng. 11, 158–168 (2017). https://doi.org/10.1007/s11709-016-0374-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-016-0374-6