Abstract

Electrochemical energy storage is one of the few options to store the energy from intermittent renewable energy sources like wind and solar. Redox flow batteries (RFBs) are such an energy storage system, which has favorable features over other battery technologies, e.g. solid state batteries, due to their inherent safety and the independent scaling of energy and power content. However, because of their low energy-density, low power-density, and the cost of components such as redox species and membranes, commercialised RFB systems like the all-vanadium chemistry cannot make full use of the inherent advantages over other systems. In principle, there are three pathways to improve RFBs and to make them viable for large scale application: First, to employ electrolytes with higher energy density. This goal can be achieved by increasing the concentration of redox species, employing redox species that store more than one electron or by increasing the cell voltage. Second, to enhance the power output of the battery cells by using high kinetic redox species, increasing the cell voltage, implementing novel cell designs or membranes with lower resistance. The first two means reduce the electrode surface area needed to supply a certain power output, thereby bringing down costs for expensive components such as membranes. Third, to reduce the costs of single or multiple components such as redox species or membranes. To achieve these objectives it is necessary to develop new battery chemistries and cell configurations. In this review, a comparison of promising cell chemistries is focused on, be they all-liquid, slurries or hybrids combining liquid, gas and solid phases. The aim is to elucidate which redox-system is most favorable in terms of energy-density, power-density and capital cost. Besides, the choice of solvent and the selection of an inorganic or organic redox couples with the entailing consequences are discussed.

Similar content being viewed by others

References

Yang Z, Zhang J, Kintner-Meyer MC W, Lu X, Choi D, Lemmon J P, Liu J. Electrochemical energy storage for green grid. Chemical Reviews, 2011, 111(5): 3577–3613

Offer G J, Howey D, Contestabile M, Clague R, Brandon N P. Comparative analysis of battery electric, hydrogen fuel cell and hybrid vehicles in a future sustainable road transport system. Energy Policy, 2010, 38(1): 24–29

Ramachandran S, Stimming U. Well to wheel analysis of low carbon alternatives for road traffic. Energy & Environmental Science, 2015, 8(11): 3313–3324

Scrosati B, Garche J. Lithium batteries: status, prospects and future. Journal of Power Sources, 2010, 195(9): 2419–2430

Armand M, Tarascon J M. Building better batteries. Nature, 2008, 451(7179): 652–657

Vetter K J. Electrochemical Kinetics—Theoretical and Experimental Aspects. English ed. New York/London: Academic Press Inc., 1967

Friedl J, Stimming U. The importance of electrochemistry for the development of sustainable mobility. In: Bruhns H, ed. Energ. Forsch. Und Konzepte, Arbeitskreis Energie (AKE) in der Deutschen Physikalischen Gesellschaft, 2014

McCreery R L. Advanced carbon electrode materials for molecular electrochemistry. Chemical Reviews, 2008, 108(7): 2646–2687

Fischer U, Saliger R, Bock V, Petricevic R, Fricke J. Carbon aerogels as electrode material in supercapacitors. Journal of Porous Materials, 1997, 4(4): 281–285

Barbieri O, Hahn M, Herzog A, Kötz R. Capacitance limits of high surface area activated carbons for double layer capacitors. Carbon, 2005, 43(6): 1303–1310

Tessonnier J P, Rosenthal D, Hansen T W, Hess C, Schuster M E, Blume R, Girgsdies F, Pfänder N, Timpe O, Su D S. Analysis of the structure and chemical properties of some commercial carbon nanostructures. Carbon, 2009, 47(7): 1779–1798

Béguin F, Presser V, Balducci A, Frackowiak E. Carbons and electrolytes for advanced supercapacitors. Advanced Materials, 2014, 26(14): 2219–2251

Ruiz V, Blanco C, Raymundo-Piñero E, Khomenko V, Béguin F, Santamaría R. Effects of thermal treatment of activated carbon on the electrochemical behaviour in supercapacitors. Electrochimica Acta, 2007, 52(15): 4969–4973

Marder M P. Condensed Matter Physics. 2nd ed. Hoboken: John Wiley & Sons, Inc., 2010

Zeier W G, Janek J. A solid future for battery development. Nature Energy, 2016, 1: 1–4

Lin D, Liu Y, Cui Y. Reviving the lithium metal anode for highenergy batteries. Nature Nanotechnology, 2017, 12(3): 194–206

Xu W, Wang J, Ding F, Chen X, Nasybulin E, Zhang Y, Zhang J G. Lithium metal anodes for rechargeable batteries. Energy & Environmental Science, 2014, 7(2): 513–537

Friedl J, Stimming U. Model catalyst studies on hydrogen and ethanol oxidation for fuel cells. Electrochimica Acta, 2013, 101: 41–58

Schmickler W, Santos E. Interfacial Electrochemistry. 2nd ed. Berlin: Springer, 2010

Zhang J, Vukmirovic M B, Xu Y, Mavrikakis M, Adzic R R. Controlling the catalytic activity of platinum-monolayer electrocatalysts for oxygen reduction with different substrates. Angewandte Chemie International Edition, 2005, 44(14): 2132–2135

Greeley J, Stephens I E L, Bondarenko A S, Johansson T P, Hansen H A, Jaramillo T F, Rossmeisl J, Chorkendorff I, Nørskov J K. Alloys of platinum and early transition metals as oxygen reduction electrocatalysts. Nature Chemistry, 2009, 1(7): 552–556

Nørskov J K, Rossmeisl J, Logadottir A, Lindqvist L, Kitchin J R, Bligaard T, Jónsson H. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. Journal of Physical Chemistry B, 2004, 108(46): 17886–17892

Marshall R J, Walsh F C. A review of some recent electrolytic cell designs. Surface Technology, 1985, 24(1): 45–77

Walsh F C, Pletcher D. Electrochemical engineering and cell design. In: Pletcher D, Tian Z-Q, Williams D (eds.), Developments in Electrochemistry: Science Inspired by Martin Felischmann. Hoboken: John Wiley & Sons, 2014: 95–112

Bond M, Henderson T L E, Mann D R, Mann T F, Thormann W, Zoski C G. A fast electron transfer rate for the oxidation of ferrocene in acetonitrile or dichloromethane at platinum disk ultramicroelectrodes. Analytical Chemistry, 1988, 60(18): 1878–1882

Friedl J, Stimming U. Determining electron transfer kinetics at porous electrodes. Electrochimica Acta, 2017, 227: 235–245

Friedl J, Bauer C M, Rinaldi A, Stimming U. Electron transfer kinetics of the VO2+/VO2 +–reaction on multi-walled carbon nanotubes. Carbon, 2013, 63: 228–239

Chalamala B R, Soundappan T, Fisher G R, Anstey M R, Viswanathan V V, Perry ML. Redox flow batteries: an engineering perspective. Proceedings of the IEEE, 2014, 102(6): 976–999

Arenas L F, de León C P, Walsh F C. Engineering aspects of the design, construction and performance of modular redox flow batteries for energy storage. Journal of Energy Storage, 2017, 11: 119–153

Remick R J, Ang P G, Hearn B E, Kalafut S J, Speckman T W. Electrically rechargeable anionically active reduction-oxidation electrical storage-supply system. US Patent 4485154, 1984

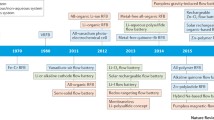

Skyllas-Kazacos M, Rychcik M, Robins R G, Fan G. New all-vanadium redox flow cell. Journal of the Electrochemical Society, 1986, 133(5): 1057–1058

Lim H S, Lackner A M, Knechtli R C. Zinc-bromine secondary battery. Journal of the Electrochemical Society, 1977, 124(8): 1154–1157

Perry M L, Darling R M, Zaffou R. High power density redox flow battery cells. ECS Transactions, 2013, 53(7): 7–16

Akhil A A, Huff G, Currier A B, Kaun B C, Rastler D M, Chen S B, Cotter A L, Bradshaw D T, Gauntlett W D. DOE / EPRI 2013 Electricity Storage Handbook in Collaboration with NRECA. Sandia National Laboratories, 2013

Eckroad S. Vanadium Redox Flow Batteries: an In-Depth Analysis. Palo Alto, CA: Electric Power Research Institute, 2007

Livermore L, Labs N, Livermore L, Labs N, Independence E, Curtright A, Apt J, Generation W, Guttromson R. arpa-e GRIDS program overview. 2010, https://arpa-e.energy.gov/sites/default/ files/documents/files/GRIDS_ProgramOverview.pdf

Zhang M, Moore M, Watson J S, Zawodzinski T A, Counce R M. Capital cost sensitivity analysis of an all-vanadium redox-flow battery. Journal of the Electrochemical Society, 2012, 159(8): A1183–A1188

Viswanathan V, Crawford A, Thaller L, Stephenson D, Kim S, Wang W, Coffey G, Balducci P, Gary Z, Li L, Sprenkle V. Estimation of capital and levelized cost for redox flow batteries. The Electrochemical Society, 2012

Noack J, Roznyatovskaya N, Herr T, Fischer P. The chemistry of redox-flow batteries. Angewandte Chemie International Edition, 2015, 54(34): 9776–9809

Pan F, Wang Q. Redox species of redox flow batteries: a review. Molecules, 2015, 20(11): 20499–20517

Weber A Z, Mench M M, Meyers J P, Ross P N, Gostick J T, Liu Q. Redox flow batteries: a review. Journal of Applied Electrochemistry, 2011, 41(10): 1137–1164

Ponce de León C, Friasferrer A, Gonzalezgarcia J, Szanto D,Walsh F. Redox flow cells for energy conversion. Journal of Power Sources, 2006, 160(1): 716–732

Leung P, Shah A A, Sanz L, Flox C, Morante J R, Xu Q, Mohamed M R, Ponce de León C, Walsh F C. Recent developments in organic redox flow batteries: a critical review. Journal of Power Sources, 2017, 360: 243–283

Zhao Y, Ding Y, Li Y, Peng L, Byon H R, Goodenough J B, Yu G. A chemistry and material perspective on lithium redox flow batteries towards high-density electrical energy storage. Chemical Society Reviews, 2015, 44(22): 7968–7996

Soloveichik G L. Flow batteries: current status and trends. Chemical Reviews, 2015, 115(20): 11533–11558

Thaller L H. Electrically rechargable redox flow cell. US Patent 3996064, 1976

Sum E, Skyllas-Kazacos M. A study of the V (II)/V (III) redox couple for redox flow cell applications. Journal of Power Sources, 1985, 15(2–3): 179–190

Rychcik M, Skyllas-Kazacos S. Evaluation of electrode materials for vanadium redox cell. Journal of Power Sources, 1987, 19(1): 45–54

Hosseiny S S, Saakes M, Wessling M. A polyelectrolyte membrane-based vanadium/air redox flow battery. Electrochemistry Communications, 2011, 13(8): 751–754

Derr I, Bruns M, Langner J, Fetyan A, Melke J, Roth C. Degradation of all-vanadium redox flow batteries (VRFB) investigated by electrochemical impedance and X-ray photoelectron spectroscopy: Part 2 electrochemical degradation. Journal of Power Sources, 2016, 325: 351–359

Miller MA, Bourke A, Quill N, Wainright J S, Lynch R P, Buckley D N, Savinell R F. Kinetic study of electrochemical treatment of carbon fiber microelectrodes leading to in situ enhancement of vanadium flow battery efficiency. Journal of the Electrochemical Society, 2016, 163(9): A2095–A2102

Yufit V, Hale B, Matian M, Mazur P, Brandon N P. Development of a regenerative hydrogen-vanadium fuel cell for energy storage applications. Journal of the Electrochemical Society, 2013, 160(6): A856–A861

Tucker MC, Srinivasan V, Ross P N, Weber A Z. Performance and cycling of the iron-ion/hydrogen redox flow cell with various catholyte salts. Journal of Applied Electrochemistry, 2013, 43(7): 637–644

Hewa Dewage H, Wu B, Tsoi A, Yufit V, Offer G, Brandon N. A novel regenerative hydrogen cerium fuel cell for energy storage applications. Journal of Materials Chemistry A, 2015, 3(18): 9446–9450

Schweiss R, Pritzl A, Meiser C. Parasitic hydrogen evolution at different carbon fiber electrodes in vanadium redox flow batteries. Journal of the Electrochemical Society, 2016, 163(9): A2089–A2094

Shah A A, Al-Fetlawi H, Walsh F C. Dynamic modelling of hydrogen evolution effects in the all-vanadium redox flow battery. Electrochimica Acta, 2010, 55(3): 1125–1139

Weber J, Samec Z, Marecek V. The effect of anion adsorption on the kinetics of the Fe3+/Fe2+ reacion on Pt and Au electrodes in HClO4. Journal of Electroanalytical Chemistry, 1978, 89(2): 271–288

Jonshagen B, Lex P. The zinc/bromine battery system for utility and remote area applications. Power Engineering Journal, 1999, 13 (3): 142–148

Duduta M, Ho B, Wood V C, Limthongkul P, Brunini V E, Carter W C, Chiang Y M. Semi-solid lithium rechargeable flow battery. Advanced Energy Materials, 2011, 1(4): 511–516

Huang Q, Wang Q. Next-generation, high-energy-density redox flow batteries. ChemPlusChem, 2015, 80(2): 312–322

Huang Q, Li H, Grätzel M, Wang Q. Reversible chemical delithiation/lithiation of LiFePO4: towards a redox flow lithiumion battery. Physical Chemistry Chemical Physics, 2013, 15(6): 1793–1797

Pan F, Yang J, Huang Q, Wang X, Huang H, Wang Q. Redox targeting of anatase TiO2 for redox flow lithium-Ion batteries. Advanced Energy Materials, 2014, 4(15): 1400567

Zanzola E, Dennison C R, Battistel A, Peljo P, Vrubel H, Amstutz V, Girault H H. Redox solid energy boosters for flow batteries: polyaniline as a case study. Electrochimica Acta, 2017, 235: 664–671

Wang W, Kim S, Chen B, Nie Z, Zhang J, Xia G G, Li L, Yang Z. A new redox flow battery using Fe/V redox couples in chloride supporting electrolyte. Energy & Environmental Science, 2011, 4(10): 4068

Izutsu K. Electrochemistry in Nonaqueous Solutions. Weinheim: Wiley-VCH GmbH & Co., 2002

Liu Q, Sleightholme A E S, Shinkle A A, Li Y, Thompson L T. Non-aqueous vanadium acetylacetonate electrolyte for redox flow batteries. Electrochemistry Communications, 2009, 11(12): 2312–2315

Sleightholme A E S, Shinkle A A, Liu Q, Li Y, Monroe C W, Thompson L T. Non-aqueous manganese acetylacetonate electrolyte for redox flow batteries. Journal of Power Sources, 2011, 196 (13): 5742–5745

Matsuda Y, Tanaka K, Okada M, Takasu Y, Morita M, Matsumura-Inoue T. A rechargeable redox battery utilizing ruthenium complexes with non-aqueous organic electrolyte. Journal of Applied Electrochemistry, 1988, 18(6): 909–914

Li Z, Li S, Liu S, Huang K, Fang D, Wang F, Peng S. Electrochemical properties of an all-organic redox flow battery using 2,2,6,6-Tetramethyl-1-Piperidinyloxy and N-Methylphthalimide. Electrochemical and Solid-State Letters, 2011, 14(12): A171–A173

Gong K, Fang Q, Gu S, Li S F Y, Yan Y. Nonaqueous redox-flow batteries: organic solvents, supporting electrolytes, and redox pairs. Energy & Environmental Science, 2015, 8(12): 3515–3530

Zoski C G. Handbook of Electrochemistry. Amsterdam: Elsevier B.V., 2007

Wei X, Xu W, Vijayakumar M, Cosimbescu L, Liu T, Sprenkle V, Wang W. TEMPO-based catholyte for high-energy density nonaqueous redox flow batteries. Advanced Materials, 2014, 26 (45): 7649–7653

Metzger J O. Lösungsmittelfreie organische synthesen. Angewandte Chemie, 1998, 110(21): 3145–3148

Helmut GREIM. Occupational Toxicants: Critical Data Evaluation for MAK Values and Classfication of Carcinogens, Band 19, The MAK-Collection for Occupational Health and Safety. Part 1: MAK Value Documentations (DFG). Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA, 2003

Toxicology Data Network. U.S. National Library of Medicine. 2017–7, https://toxnet.nlm.nih.gov

Ejigu A, Greatorex-Davies P A, Walsh D A. Room temperature ionic liquid electrolytes for redox flow batteries. Electrochemistry Communications, 2015, 54: 55–59

Roth E P, Orendorff C J. How electrolytes influence battery safety. Interface, 2012, 21: 45–50

Friedl J, Markovits E II, Herpich M, Feng G, Kornyshev A A, Stimming U. Interface between an Au(111) surface and an ionic liquid: the influence of water on the double-layer capacitance. ChemElectroChem, 2016, 71: 311–315

O’Mahony A M, Silvester D S, Aldous L, Hardacre C, Compton R G. Effect of water on the electrochemical window and potential limits of room-temperature ionic liquids. Journal of Chemical & Engineering Data, 2008, 53(12): 2884–2891

Anderson T M, Iii H D P. Ionic liquid flow batteries. 2015–6, https://www.osti.gov/scitech/biblio/1256242

Pratt H D III, Leonard J C, Steele L A M, Staiger C L, Anderson T M. Copper ionic liquids: examining the role of the anion in determining physical and electrochemical properties. Inorganica Chimica Acta, 2013, 396: 78–83

Prifti H, Parasuraman A, Winardi S, Lim T M, Skyllas-Kazacos M. Membranes for redox flow battery applications. Membranes (Basel), 2012, 2(2): 275–306

Maurya S, Shin S H, Kim Y, Moon S H. A review on recent developments of anion exchange membranes for fuel cells and redox flow batteries. RSC Advances, 2015, 5(47): 37206–37230

Tang Z. Characterization techniques and electrolyte separator performance investigation for all vanadium redox flow battery. Dissertation for the Doctoral Degree. Knoxville: University of Tennessee, 2013

Mohammadi T, Kazacos M S. Modification of anion-exchange membranes for vanadium redox flow battery applications. Journal of Power Sources, 1996, 63(2): 179–186

Mohammadi T, Skyllas-Kazacos M. Characterisation of novel composite membrane for redox flow battery applications. Journal of Membrane Science, 1995, 98(1–2): 77–87

Mohammadi T, Chieng S C, Skyllas Kazacos M. Water transport study across commercial ion exchange membranes in the vanadium redox flow battery. Journal of Membrane Science, 1997, 133(2): 151–159

Yuan Z, Duan Y, Zhang H, Li X, Zhang H, Vankelecom I. Advanced porous membranes with ultra-high selectivity and stability for vanadium flow battery. Energy & Environmental Science, 2015, 9: 22–24

Janoschka T, Martin N, Martin U, Friebe C, Morgenstern S, Hiller H, Hager M D, Schubert U S. An aqueous, polymer-based redoxflow battery using non-corrosive, safe, and low-cost materials. Nature, 2015, 527(7576): 78–81

Cathro K, Cedzynska K, Constable D C, Hoobin P M. Selection of quaternary ammonium bromides for use in zinc/bromine cells. Journal of Power Sources, 1986, 18(4): 349–370

Yang H S, Park J H, Ra H W, Jin C S, Yang J H. Critical rate of electrolyte circulation for preventing zinc dendrite formation in a zinc-bromine redox flow battery. Journal of Power Sources, 2016, 325: 446–452

Higashi S, Lee S W, Lee J S, Takechi K, Cui Y. Avoiding short circuits from zinc metal dendrites in anode by backside-plating configuration. Nature Communications, 2016, 7: 11801

Rychcik M, Skyllas-Kazacos M. Characteristics of a new allvanadium redox flow battery. Journal of Power Sources, 1988, 22 (1): 59–67

Ulaganathan M, Aravindan V, Yan Q, Madhavi S, Skyllas-kazacos M, Lim T M. Recent advancements in all-vanadium redox flow batteries. Advanced Materials, 2016, 3: 1500309

Skyllas-Kazacos M. Thermal stability of concentrated V(V) electrolytes in the vanadium redox cell. Journal of the Electrochemical Society, 1996, 143(4): L86

Li L, Kim S, Wang W, Vijayakumar M, Nie Z, Chen B, Zhang J, Xia G, Hu J, Graff G, Liu J, Yang Z. A stable vanadium redox-flow battery with high energy density for large-scale energy storage. Advanced Energy Materials, 2011, 1(3): 394–400

Holland-Cunz M V, Friedl J, Stimming U. Anion effects on the redox kinetics of positive electrolyte of the all-vanadium redox flow battery. Journal of Electroanalytical Chemistry, 2017, in press, https://doi.org//10.1016/j.elechem.2017.10.061

Roe S, Menictas C, Skyllas-Kazacos M. A high energy density vanadium redox flow battery with 3M vanadium electrolyte. Journal of the Electrochemical Society, 2016, 163(1): A5023–A5028

Skyllas-Kazacos M, Kazacos M. Stabilised electrolyte solutions, methods of preparation thereof and redox cells and batteries containing stabilised electrolyte solutions. European Patent EP0729648, 1995

Lei Y, Liu S Q, Gao C, Liang X X, He Z X, Deng Y H, He Z. Effect of amino acid additives on the positive electrolyte of vanadium redox flow batteries. Journal of the Electrochemical Society, 2013, 160(4): A722–A727

Chang F, Hu C, Liu X, Liu L, Zhang J. Coulter dispersant as positive electrolyte additive for the vanadium redox flow battery. Electrochimica Acta, 2012, 60: 334–338

Zhang J, Li L, Nie Z, Chen B, Vijayakumar M, Kim S, Wang W, Schwenzer B, Liu J, Yang Z. Effects of additives on the stability of electrolytes for all-vanadium redox flow batteries. Journal of Applied Electrochemistry, 2011, 41(10): 1215–1221

Li S, Huang K, Liu S, Fang D, Wu X, Lu D, Wu T. Effect of organic additives on positive electrolyte for vanadium redox battery. Electrochimica Acta, 2011, 56(16): 5483–5487

Nguyen T D, Whitehead A, Scherer G G, Wai N, Oo M O, Bhattarai A, Chandra G P, Xu Z J. The oxidation of organic additives in the positive vanadium electrolyte and its effect on the performance of vanadium redox flow battery. Journal of Power Sources, 2016, 334: 94–103

Shinkle A A, Sleightholme A E S, Thompson L T, Monroe C W. Electrode kinetics in non-aqueous vanadium acetylacetonate redox flow batteries. Journal of Applied Electrochemistry, 2011, 41(10): 1191–1199

Shinkle A A, Sleightholme A E S, Griffith L D, Thompson L T, Monroe C W. Degradation mechanisms in the non-aqueous vanadium acetylacetonate redox flow battery. Journal of Power Sources, 2012, 206: 490–496

Shinkle A A, Pomaville T J, Sleightholme A E S, Thompson L T, Monroe C W. Solvents and supporting electrolytes for vanadium acetylacetonate flow batteries. Journal of Power Sources, 2014, 248: 1299–1305

Saraidaridis J D, Bartlett B M, Monroe C W. Spectroelectrochemistry of vanadium acetylacetonate and chromium acetylacetonate for symmetric nonaqueous flow batteries. Journal of the Electrochemical Society, 2016, 163(7): A1239–A1246

Liu Q, Shinkle A A, Li Y, Monroe C W, Thompson L T, Sleightholme A E S. Non-aqueous chromium acetylacetonate electrolyte for redox flow batteries. Electrochemistry Communications, 2010, 12(11): 1634–1637

Goulet M, Kjeang E. Co-laminar flow cells for electrochemical energy conversion. Journal of Power Sources, 2014, 260: 186–196

Goulet MA, Ibrahim O A, Kim WH J J, Kjeang E. Maximizing the power density of aqueous electrochemical flow cells with in operando deposition. Journal of Power Sources, 2017, 339: 80–85

Ressel S, Laube A, Fischer S, Chica A, Flower T, Struckmann T. Performance of a vanadium redox flow battery with tubular cell design. Journal of Power Sources, 2017, 355: 199–205

Skyllas-Kazacos M. Novel vanadium chloride/polyhalide redox flow battery. Journal of Power Sources, 2003, 124(1): 299–302

Walsh F C C. Electrochemical technology for environmental treatment and clean energy conversion. Pure and Applied Chemistry, 2001, 73(12): 1819–1837

Review of Electrical Energy Storage Technologies and Systems and of their Potential for the UK, 2004. http://webarchive. nationalarchives.gov.uk/20100919182219/http://www.ensg.gov. uk/assets/dgdti00055.pdf

Li B, Nie Z, Vijayakumar M, Li G, Liu J, Sprenkle V, Wang W. Ambipolar zinc-polyiodide electrolyte for a high-energy density aqueous redox flow battery. Nature Communications, 2015, 6(1): 6303

Janoschka T, Martin N, Hager M D, Schubert U S. An aqueous redox-flow battery with high capacity and power: the TEMPTMA/MV system. Angewandte Chemie International Edition, 2016, 55 (46): 14427–14430

Winsberg J, Hagemann T, Muench S, Friebe C, Häupler B, Janoschka T, Morgenstern S, Hager M D, Schubert U S. Poly (boron-dipyrromethene)-A redox-active polymer class for polymer redox-flow batteries. Chemistry of Materials, 2016, 28(10): 3401–3405

Pratt H D III, Hudak N S, Fang X, Anderson T M. A polyoxometalate flow battery. Journal of Power Sources, 2013, 236: 259–264

Pratt H D III, Pratt W R, Fang X, Hudak N S, Anderson T M. Mixed-metal, structural, and substitution effects of polyoxometalates on electrochemical behavior in a redox flow battery. Electrochimica Acta, 2014, 138: 210–214

Friedl J, Al-Oweini R, Herpich M, Keita B, Kortz U, Stimming U. Electrochemical studies of tri-manganese substituted keggin polyoxoanions. Electrochimica Acta, 2014, 141: 357–366

Kremleva A, Aparicio P A, Genest A, Rösch N. Quantum chemical modeling of tri-Mn-substituted W-based Keggin polyoxoanions. Electrochimica Acta, 2017, 231: 659–669

Keita B, Nadjo L. New oxometalate-based materials for catalysis and electrocatalysis. Materials Chemistry and Physics, 1989, 22(1–2): 77–103

Christian J B, Smith S P E, Whittingham M S, Abruña H D. Tungsten based electrocatalyst for fuel cell applications. Electrochemistry Communications, 2007, 9(8): 2128–2132

Friedl J, Bauer C, Al-Oweini R, Yu D, Kortz U, Hoster H E, Stimming U. Investigation on polyoxometalates for the application in redox flow batteries. In: 222th ECS Meet., Honolulu, HI, 2012, http://ma.ecsdl.org/content/MA2012-02/51/3551.short

Liu Y, Lu S, Wang H, Yang C, Su X, Xiang Y. An aqueous redox flow battery with a Tungsten–Cobalt heteropolyacid as the electrolyte for both the anode and cathode. Advanced Energy Materials, 2017, 7: 2–7

Pope M, Varga G M Jr. Heteropoly blues. I. Reduction stoichiometries and reduction potentials of some 12-tungstates. Inorganic Chemistry, 1966, 5(7): 1249–1254

Huskinson B, Marshak M P, Suh C, Er S, Gerhardt M R, Galvin C J, Chen X, Aspuru-Guzik A, Gordon R G, Aziz M J. A metal-free organic-inorganic aqueous flow battery. Nature, 2014, 505(7482): 195–198

Chen Q, Gerhardt M R, Hartle L, Aziz M J. A quinone-bromide flow battery with 1 W/cm2 power density. Journal of the Electrochemical Society, 2015, 163(1): A5010–A5013

Chen Q, Gerhardt M R, Aziz M J. Dissection of the voltage losses of an acidic quinone redox flow battery. Journal of the Electrochemical Society, 2017, 164(6): A1126–A1132

Chen Q, Eisenach L, Aziz M J. Cycling analysis of a quinonebromide redox flow battery. Journal of the Electrochemical Society, 2016, 163(1): A5057–A5063

Carney T J, Collins S J, Moore J S, Brushett F R. Concentrationdependent dimerization of anthraquinone disulfonic acid and its impact on charge storage. Chemistry of Materials, 2017, 29(11): 4801–4810

Lin K, Chen Q, Gerhardt MR, Tong L, Kim S B, Eisenach L, Valle A W, Hardee D, Gordon R G, Aziz M J, Marshak M P. Alkaline quinone flow battery. Science, 2015, 349(6225): 1529–1532

Lin K, Gómez-Bombarelli R, Beh E S, Tong L, Chen Q, Valle A, Aspuru-Guzik A, Aziz M J, Gordon R G. A redox-flow battery with an alloxazine-based organic electrolyte. Nature Energy, 2016, 1(9): 16102

Rabiul Islam F M, Al Mamun K, Amanullah M T O. Smart Energy Grid Design for Island Countries. Cham: Springer, 2017

Johnson D A, Reid M A. Chemical and electrochemical behavior of the Cr(lll)/Cr(ll) half-cell in the iron-chromium redox energy system. Journal of the Electrochemical Society, 1985, 132(5): 1058–1062

Nice A W. NASA redox system development project status. In: 4th Battery and Electrochemical Contractors Conference, Washington, 1981

Zhang H. Development and application of high performance VRB technology. In: IFBF 2017 International Flow Battery Forum, Manchester, UK, 2017

Scamman D P, Reade G W, Roberts E P L. Numerical modelling of a bromide-polysulphide redox flow battery. Part 1: Modelling approach and validation for a pilot-scale system. Journal of Power Sources, 2009, 189(2): 1220–1230

Morrissey P. Regenesys: a new energy storage technology. International Journal of Ambient Energy, 2000, 21(4): 213–220

Leung P K, Ponce de León C, Walsh F C. An undivided zinc–cerium redox flow battery operating at room temperature (295K). Electrochemistry Communications, 2011, 13(8): 770–773

Dong Y R, Kaku H, Hanafusa K, Moriuchi K, Shigematsu T. A novel titanium/manganese redox flow battery. ECS Transactions, 2015, 69(18): 59–67

Zeng Y K, Zhao T S, Zhou X L, Wei L, Jiang H R. A low-cost ironcadmium redox flow battery for large-scale energy storage. Journal of Power Sources, 2016, 330: 55–60

Cheng J, Zhang L, Yang Y S, Wen Y H, Cao G P, Wang X D. Preliminary study of single flow zinc-nickel battery. Electrochemistry Communications, 2007, 9(11): 2639–2642

Morita M, Tanaka Y, Tanaka K, Matsuda Y T, Matsumura-Inoue T. Matsumura-inoue, electrochemical oxidation of ruthenium and iron complexes at rotating disk electrode in acetonitrile solution. Bulletin of the Chemical Society of Japan, 1988, 61(8): 2711–2714

Chakrabarti M H, Roberts E P L, Bae C, Saleem M. Ruthenium based redox flow battery for solar energy storage. Energy Conversion and Management, 2011, 52(7): 2501–2508

Cappillino P J, Pratt H D, Hudak N S, Tomson N C, Anderson T M, Anstey M R. Application of redox non-innocent ligands to nonaqueous flow battery electrolytes. Advanced Energy Materials, 2014, 4: 2–6

Hwang B, Park M S, Kim K. Ferrocene and cobaltocene derivatives for non-aqueous redox flow batteries. ChemSusChem, 2015, 8(2): 310–314

Zhang D, Lan H, Li Y. The application of a non-aqueous bis (acetylacetone)ethylenediamine cobalt electrolyte in redox flow battery. Journal of Power Sources, 2012, 217: 199–203

Xu Y,Wen Y, Cheng J, Cao G, Yang Y. Study on a single flow acid Cd-chloranil battery. Electrochemistry Communications, 2009, 11 (7): 1422–1424

Yang B, Hoober-Burkhardt L, Wang F, Surya Prakash G K, Narayanan S R. An inexpensive aqueous flow battery for largescale electrical energy storage based on water-soluble organic redox couples. Journal of the Electrochemical Society, 2014, 161 (9): A1371–A1380

Oh S H, Lee C W, Chun D H, Jeon J D, Shim J, Shin K H, Yang J H. A metal-free and all-organic redox flow battery with polythiophene as the electroactive species. Journal of Materials Chemistry A, 2014, 2(47): 19994–19998

Weinberg D R, Gagliardi C J, Hull J F, Murphy C F, Kent C A, Westlake B C, Paul A, Ess D H, McCafferty D G, Meyer T J. Proton-coupled electron transfer. Chemical Reviews, 2012, 112(7): 4016–4093

Dmello R, Milshtein J D, Brushett F R, Smith K C. Cost-driven materials selection criteria for redox flow battery electrolytes. Journal of Power Sources, 2016, 330: 261–272

Schwenzer B, Zhang J, Kim S, Li L, Liu J, Yang Z. Membrane development for vanadium redox flow batteries. ChemSusChem, 2011, 4(10): 1388–1406

Wiedemann E, Heintz A, Lichtenthaler R N. Transport properties of vanadium ions in cation exchange membranes: determination of diffusion coefficients using a dialysis cell. Journal of Membrane Science, 1998, 141(2): 215–221

Ding C, Zhang H, Li X, Liu T, Xing F. Vanadium flow battery for energy storage: prospects and challenges. Journal of Physical Chemistry Letters, 2013, 4(8): 1281–1294

Beh E S, De Porcellinis D, Gracia R L, Xia K T, Gordon R G, Aziz M J. A neutral pH aqueous organic–organometallic redox flow battery with extremely high capacity retention. ACS Energy Letter, 2017, 2(3): 639–644

Vijayakumar M, Bhuvaneswari MS, Nachimuthu P, Schwenzer B, Kim S, Yang Z, Liu J, Graff G L, Thevuthasan S, Hu J. Spectroscopic investigations of the fouling process on Nafion membranes in vanadium redox flow batteries. Journal of Membrane Science, 2011, 366(1–2): 325–334

Derr I, Fetyan A, Schutjajew K, Roth C. Electrochemical analysis of the performance loss in all vanadium redox flow batteries using different cut-off voltages. Electrochimica Acta, 2017, 224: 9–16

Darling R, Gallagher K G, Kowalski J A, Ha S, Brushett F R. Pathways to low-cost electrochemical energy storage: a comparison of aqueous and nonaqueous flow batteries. Energy & Environmental Science, 2014, 7(11): 3459–3477

U. S. Department of Energy Headquarters Advanced Research Projects Agency–Energy (ARPA-E). Grid-Scale Rampable Intermittent Dispatchable Storage (GRIDS). 2010, https://www. osti.gov/scitech/biblio/1046668

Winsberg J, Hagemann T, Janoschka T, Hager M D, Schubert U S. Redox-flow batteries: from metals to organic redox-active materials. Angewandte Chemie International Edition, 2017, 56 (3): 686–711

Zeng Y K, Zhao T S, An L, Zhou X L, Wei L. A comparative study of all-vanadium and iron-chromium redox flow batteries for large-scale energy storage. Journal of Power Sources, 300(2015): 438–443

Acknowledgements

This work was supported by Newcastle University and Siemens AG.

Author information

Authors and Affiliations

Additional information

Matthäa Verena Holland-Cunz, née Schwob, studied Bachelor and Master of Chemistry at University of Cologne, Germany, and completed her master thesis with focus on the investigation of new electrode materials for redox flow batteries at FraunhoferInstitut in Freiburg im Breisgau, Germany. Since 2016 she is enrolled as Ph.D. student in Physical Chemistry at Newcastle University. Her research is about the electron transfer kinetics of the vanadium redox reaction and the investigation of new advanced materials for redox flow batteries.

Faye Cording is a postgraduate student in Chemistry of the School of Natural and Environmental Sciences at Newcastle University. She completed undergraduate studies in Chemistry at Northumbria University before joining Newcastle University to study new materials for redox flow batteries.

Dr. Jochen Friedl is a research associate in Chemistry of the School of Natural and Environmental Sciences at Newcastle University. For the past 7 years he has been researching redox flow batteries, with a focus on the electron transfer kinetics of the vanadium redox reactions and novel cell chemistries. His investigations of the electron transfer of vanadium revealed the influence of oxygen functional groups on the redox reactions that are at the heart of the anolyte and the catholyte of the all-vanadium redox flow battery. He helped to develop and scale up a novel redox-chemistry based on nano-sized electron shuttles from batteries that produced some mA to a single cell that can deliver 100 A. Author of 20 publications, he has received his doctorate from the Technical University of Munich, Germany, with highest distinction in 2015.

Ulrich Stimming was educated at the Free University of Berlin, Germany, where he received his Diploma degree in Chemistry and a Ph.D. in Physical Chemistry.

Prof. Stimming is currently a Professor of Physical Chemistry at Newcastle University, UK. Previously, he was Head of the School of Chemistry at Newcastle University. He was CEO and Scientific Advisor and Principal Investigator of TUM Create in Singapore. He had a Chair of Technical Physics and was Professor of Chemistry at Technical University Munich (TUM). Prior to that he was a Director at the Research Center Jülich and before a member of the faculty of Columbia University in New York, USA. He has visiting appointments at various universities including Shanghai Jiao Tong University and University of Science and Technology of China.

Currently, he is the Director of the North-East Centre of Energy Materials (NECEM) funded by EPSRC. He also directs a large battery project at Newcastle University on degradation of Li-Ion batteries in cooperation with Cambridge, UCL and Glasgow universities. Prof. Stimming is the founder and Editor-in-chief of the scientific journal Fuel Cells-From Fundamentals to Systems, VCH-Wiley. He coordinated for the Association of Leading Technical Universities in Germany (TU9) a research network of a total of 8 universities in electro-mobility between Germany and China, and was the co-director of the Joint “Institute for Advanced Power Sources” of TU Munich and Tsinghua University, Beijing, from 2010 to 2014. He has 300 + publications and numerous patents.

Rights and permissions

About this article

Cite this article

Holland-Cunz, M.V., Cording, F., Friedl, J. et al. Redox flow batteries—Concepts and chemistries for cost-effective energy storage. Front. Energy 12, 198–224 (2018). https://doi.org/10.1007/s11708-018-0552-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-018-0552-4