Abstract

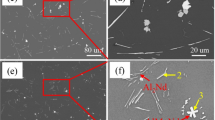

The magnesium aluminum and zinc aluminum layered double hydroxides intercalated with NO -3 (MgAl-NO3-LDH and ZnAl-NO3-LDH) were prepared by the coprecipitation method, and the magnesium aluminum and the zinc aluminum layered double hydroxides intercalated with VO - x (MgAl-VO x -LDH and ZnAl-VO x -LDH) were prepared by the anion-exchange method. Morphologies, microstructures and chemical compositions of LDHs were investigated by SEM, EDS, XRD, FTIR, Raman and TG analyses. The immersion tests were carried to determine the corrosion inhibition properties of MgAl-VO x -LDH and ZnAl-VO x -LDH on AZ31 Mg alloys. The results showed that ZnAl-VO x -LDH possesses the best anion-exchange and inhibition abilities. The influence of treatment parameters on microstructures of LDHs were discussed. Additionally, an inhibition mechanism for ZnAl-VO x -LDH on the AZ31 magnesium alloy was proposed and discussed.

Similar content being viewed by others

References

Zhou M, Yan L, Ling H, et al. Design and fabrication of enhanced corrosion resistance Zn–Al layered double hydroxides films based anion-exchange mechanism on magnesium alloys. Applied Surface Science, 2017, 404: 246–253

Zhou T, Zhu Y Z, Li X, et al. Surface functionalization of biomaterials by radical polymerization. Progress in Materials Science, 2016, 83: 191–235

Zhang F, Zhang C L, Song L, et al. Fabrication of the superhydrophobic surface on magnesium alloy and its corrosion resistance. Journal of Materials Science and Technology, 2015, 31 (11): 1139–1143

Zhao Y B, Liu H P, Li C Y, et al. Corrosion resistance and adhesion strength of a spin-assisted layer-by-layer assembled coating on AZ31 magnesium alloy. Applied Surface Science, 2018, 434: 787–795

Wu C S, Zhang Z, Cao F H, et al. Study on the anodizing of AZ31 magnesium alloys in alkaline borate solutions. Applied Surface Science, 2007, 253(8): 3893–3898

Yang Q, Yuan W, Liu X, et al. Atomic layer deposited ZrO2 nanofilm on Mg–Sr alloy for enhanced corrosion resistance and biocompatibility. Acta Biomaterialia, 2017, 58: 515–526

Yan H, Wang J, Zhang Y, et al. Preparation and inhibition properties of molybdate intercalated ZnAlCe layered double hydroxide. Journal of Alloys and Compounds, 2016, 678: 171–178

Forero López A D, Lehr I L, Saidman S B. Anodisation of AZ91D magnesium alloy in molybdate solution for corrosion protection. Journal of Alloys and Compounds, 2017, 702: 338–345

Fraqueza G, Ohlin C A, Casey WH, et al. Sarcoplasmic reticulum calcium ATPase interactions with decaniobate, decavanadate, vanadate, tungstate and molybdate. Journal of Inorganic Biochemistry, 2012, 107(1): 82–89

Kiaei Z, Haghtalab A. Experimental study of using Ca-DTPMP nanoparticles in inhibition of CaCO3 scaling in a bulk water process. Desalination, 2014, 338(1): 84–92

Tang Y, Cao Z, Xu J, et al. Titanate matrices as potential corrosion inhibitor nanocontainers. Corrosion Science, 2014, 88: 487–490

Tedim J, Poznyak S K, Kuznetsova A, et al. Enhancement of active corrosion protection via combination of inhibitor-loaded nanocontainers. ACS Applied Materials & Interfaces, 2010, 2(5): 1528–1535

Hu J, Gan M, Ma L, et al. Synthesis and anticorrosive properties of polymer–clay nanocomposites via chemical grafting of polyaniline onto Zn–Al layered double hydroxides. Surface and Coatings Technology, 2014, 240(7): 55–62

Zhang F, Liu Z G, Zeng R C, et al. Corrosion resistance of Mg–Al- LDH coating on magnesium alloy AZ31. Surface and Coatings Technology, 2014, 258: 1152–1158

Zhang F, Zhang C L, Zeng R C, et al. Corrosion resistance of the superhydrophobic Mg(OH)2/Mg–Al layered double hydroxide coatings on magnesium alloys. Metals, 2016, 6(12): 85–98

Shkirskiy V, Keil P, Hintze-Bruening H, et al. Factors affecting MoO4 2–inhibitor release from Zn2Al based layered double hydroxide and their implication in protecting hot dip galvanized steel by means of organic coatings. ACS Applied Materials & Interfaces, 2015, 7(45): 25180–25192

Hang T T X, Truc T A, Duong N T, et al. Layered double hydroxides as containers of inhibitors in organic coatings for corrosion protection of carbon steel. Progress in Organic Coatings, 2012, 74(2): 343–348

Meng Z, Zhang Y, Zhang Q, et al. Novel synthesis of layered double hydroxides (LDHs) from zinc hydroxide. Applied Surface Science, 2017, 396: 799–803

Zeng R C, Liu Z G, Zhang F, et al. Corrosion of molybdate intercalated hydrotalcite coating on AZ31 Mg alloy. Journal of Materials Chemistry A: Materials for Energy and Sustainability, 2014, 2(32): 13049–13057

Zeng R C, Li X T, Liu Z G, et al. Corrosion resistance of Zn–Al layered double hydroxide/poly(lactic acid) composite coating on magnesium alloy AZ31. Frontiers of Materials Science, 2015, 9 (4): 355–365

Tedim J, Kuznetsova A, Salak A N, et al. Zn–Al layered double hydroxides as chloride nanotraps in active protective coatings. Corrosion Science, 2012, 55: 1–4

Salak A N, Tedim J, Kuznetsova A I, et al. Anion exchange in Zn–Al layered double hydroxides: In situ X-ray diffraction study. Chemical Physics Letters, 2010, 495(1–3): 73–76

Wang Y, Wu P, Li Y, et al. Structural and spectroscopic study of tripeptide/layered double hydroxide hybrids. Journal of Colloid and Interface Science, 2013, 394: 564–572

Huang Z, Wang S, Wang J, et al. Exfoliation-restacking synthesis of coal-layered double hydroxide nanosheets/reduced graphene oxide composite for high performance supercapacitors. Electrochimica Acta, 2015, 152: 117–125

Abbasian M. Exfoliated poly (styrene-co-methylstyrene) graftedpolyaniline/layered double hydroxide nanocomposite synthesized by solvent blending method. Journal of Applied Polymer Science, 2011, 122(4): 2573–2582

Wang Y, Zhang D. Synthesis, characterization, and controlled release anticorrosion behavior of benzoate intercalated Zn–Al layered double hydroxides. Materials Research Bulletin, 2011, 46 (11): 1963–1968

Zhang F, Zhao L, Chen H, et al. Corrosion resistance of superhydrophobic layered double hydroxide films on aluminum. Angewandte Chemie International Edition, 2008, 47(13): 2466–2469

Zhu Y Z, Liu X M, Yeung K W K, et al. Biofunctionalization of carbon nanotubes/chitosan hybrids on Ti implants by atom layer deposited ZnO nanostructures. Applied Surface Science, 2017, 400: 14–23

Kagunya W, Baddour-Hadjean R, Kooli F, et al. Vibrational modes in layered double hydroxides and their calcined derivatives. Chemical Physics, 1998, 236(1–3): 225–234

Acharya H, Srivastava S K, Bhowmick A K. Synthesis of partially exfoliated EPDM/LDH nanocomposites by solution intercalation: Structural characterization and properties. Composites Science and Technology, 2007, 67(13): 2807–2816

Basu D, Das A, Stöckelhuber K W, et al. Advances in layered double hydroxide (LDH)-based elastomer composites. Progress in Polymer Science, 2014, 39(3): 594–626

Costa F R, Leuteritz A, Wagenknecht U, et al. Intercalation of Mg–Al layered double hydroxide by anionic surfactants: Preparation and characterization. Applied Clay Science, 2008, 38(3–4): 153–164

Zhang X, Qi F, Li S, et al. A mechanochemical approach to get stunningly uniform particles of magnesium–aluminum-layered double hydroxides. Applied Surface Science, 2012, 259: 245–251

Choudary B. Molybdate-exchanged Mg–Al-LDH catalyst: an ecocompatible route for the synthesis of β-bromostyrenes in aqueous medium. Catalysis Communications, 2004, 5(5): 215–219

Zhang C L, Zhang F, Song L, et al. Corrosion resistance of a superhydrophobic surface on micro-arc oxidation coated Mg–Li–Ca alloy. Journal of Alloys and Compounds, 2017, 728: 815–826

Liu F, Song Y W, Shan D Y, et al. Corrosion behavior of AZ31 magnesium alloy in simulated acid rain solution. Transactions of Nonferrous Metals Society of China, 2010, 20(s2): 638–642

Guo L, Zhang F, Song L, et al. Corrosion resistance of ceria/polymethyltrimethoxysilane modified magnesium hydroxide coating on AZ31 magnesium alloy. Surface and Coatings Technology, 2017, 328: 121–133

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51601108, 51571134, 21676285), the Natural Science Foundation of Shandong Province (Grant No. 2016ZRB01A62), the SDUST Research Fund (No. 2014TDJH104), and the Ministry-Province jointly-constructed cultivation base for the State Key Laboratory of Processing for Non-Ferrous Metal and Featured Materials, Guangxi Zhuang Autonomous Region.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Guo, L., Zhang, F., Lu, JC. et al. A comparison of corrosion inhibition of magnesium aluminum and zinc aluminum vanadate intercalated layered double hydroxides on magnesium alloys. Front. Mater. Sci. 12, 198–206 (2018). https://doi.org/10.1007/s11706-018-0415-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11706-018-0415-2