Abstract

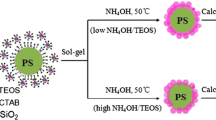

Hollow silica spheres possessing excellent mechanical properties were successfully prepared through a layer-by-layer process using uniform polystyrene (PS) latex fabricated by dispersion polymerization as template. The formation of hollow SiO2 micro-spheres, structures and properties were observed in detail by zeta potential, SEM, TEM, FTIR, TGA and nitrogen sorption porosimetry. The results indicated that the hollow spheres were uniform with particle diameter of 1.6 μm and shell thickness of 150 nm. The surface area was 511 m2/g and the pore diameter was 8.36 nm. A new stationary phase for HPLC was obtained by using C18-derivatized hollow SiO2 micro-spheres as packing materials and the chromatographic properties were evaluated for the separation of some regular small molecules. The packed column showed low column pressure, high values of efficiency (up to about 43 000 plates/m) and appropriate asymmetry factors.

Similar content being viewed by others

References

Wang L, Wei W, Xia Z, et al. Recent advances in materials for stationary phases of mixed-mode high-performance liquid chromatography. Trends in Analytical Chemistry, 2016, 80: 495–506

Unger K K, Skudas R, Schulte M M. Particle packed columns and monolithic columns in high-performance liquid chromatography — comparison and critical appraisal. Journal of Chromatography A, 2008, 1184(1–2): 393–415

Zhao B B, Zhang Y, Tang T, et al. Silica based stationary phases for high performance liquid chromatography. Progress in Chemistry, 2012, 24(1): 122–130 (in Chinese)

Zhao L, Yang L, Wang Q. Silica-based polypeptide-monolithic stationary phase for hydrophilic chromatography and chiral separation. Journal of Chromatography A, 2016, 1446: 125–133

Qiu H, Liang X, Sun M, et al. Development of silica-based stationary phases for high-performance liquid chromatography. Analytical and Bioanalytical Chemistry, 2011, 399(10): 3307–3322

Miyabe K. New moment equations for chromatography using various stationary phases of different structural characteristics. Analytical Chemistry, 2007, 79(19): 7457–7472

Ali I, Al-Othman Z A, Al-Za’abi M. Superficially porous particles columns for super fast HPLC separations. Biomedical Chromatography, 2012, 26(8): 1001–1008

Abrahim A, Al-Sayah M, Skrdla P, et al. Practical comparison of 2.7 µm fused-core silica particles and porous sub-2 µm particles for fast separations in pharmaceutical process development. Journal of Pharmaceutical and Biomedical Analysis, 2010, 51 (1): 131–137

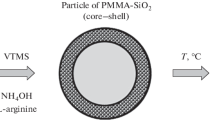

Dong H, Brennan J D. Rapid fabrication of core–shell silica particles using a multilayer-by-multilayer approach. Chemical Communications, 2011, 47(4): 1207–1209

Wang Y, Su X, Ding P, et al. Shape-controlled synthesis of hollow silica colloids. Langmuir, 2013, 29(37): 11575–11581

Caruso F, Caruso R A, Möhwald H. Nanoengineering of inorganic and hybrid hollow spheres by colloidal templating. Science, 1998, 282(5391): 1111–1114

Liu J, Liu F, Gao K, et al. Recent developments in the chemical synthesis of inorganic porous capsules. Journal of Materials Chemistry, 2009, 19(34): 6073–6084

Dash B C, Réthoré G, Monaghan M, et al. The influence of size and charge of chitosan/polyglutamic acid hollow spheres on cellular internalization, viability and blood compatibility. Biomaterials, 2010, 31(32): 8188–8197

Zeng H, Xu X, Bando Y, et al. Template deformation-tailored ZnO nanorod/nanowire arrays: full growth control and optimization of field-emission. Advanced Functional Materials, 2009, 19(19): 3165–3172

Zhao B, Collinson M M. Hollow silica capsules with well-defined asymmetric windows in the shell. Langmuir, 2012, 28(19): 7492–7497

Dong Z, Lai X, Halpert J E, et al. Accurate control of multishelled ZnO hollow microspheres for dye-sensitized solar cells with high efficiency. Advanced Materials, 2012, 24(8): 1046–1049

Strandwitz N C, Shaner S, Stucky G D. Compositional tunability and high temperature stability of ceria–zirconia hollow spheres. Journal of Materials Chemistry, 2011, 21(29): 10672–10675

Zou H, Wu S, Shen J. Polymer/silica nanocomposites: preparation, characterization, properties, and applications. Chemical Reviews, 2008, 108(9): 3893–3957

Hu H, Zhou H, Liang J, et al. Facile synthesis of aminofunctionalized hollow silica microspheres and their potential application for ultrasound imaging. Journal of Colloid and Interface Science, 2011, 358(2): 392–398

Hebalkar N Y, Acharya S, Rao T N. Preparation of bi-functional silica particles for antibacterial and self cleaning surfaces. Journal of Colloid and Interface Science, 2011, 364(1): 24–30

Karabacak R B, Erdem M, Yurdakal S, et al. Facile two-step preparation of polystyrene/anatase TiO2 core/shell colloidal particles and their potential use as an oxidation photocatalyst. Materials Chemistry and Physics, 2014, 144(3): 498–504

Demirörs A F, van Blaaderen A, Imhof A, et al. Synthesis of eccentric titania–silica core–shell and composite particles. Chemistry of Materials, 2009, 21(6): 979–984

Wen H Y, Gao G, Han Z R, et al. Magnetite-coated polystyrene hybrid microspheres prepared by miniemulsion polymerization. Polymer International, 2008, 57(4): 584–591

Nithyadevi D, Kumar P S, Mangalaraj D, et al. Improved microbial growth inhibition activity of bio-surfactant induced Ag–TiO2 core shell nanoparticles. Applied Surface Science, 2015, 327: 504–516

Stephenson R C, Partch R E. Metal oxide and metal carbide thin film coatings on large spherical particles. MRS Online Proceedings Library, 1996, 458: 435

Yuan J, Wan D, Yang Z. A facile method for the fabrication of thiol-functionalized hollow silica spheres. The Journal of Physical Chemistry C, 2008, 112(44): 17156–17160

Pu H, Zhang X, Yuan J, et al. A facile method for the fabrication of vinyl functionalized hollow silica spheres. Journal of Colloid and Interface Science, 2009, 331(2): 389–393

Deng T S, Marlow F. Synthesis of monodisperse polystyrene@- vinyl-SiO2 core–shell particles and hollow SiO2 spheres. Chemistry of Materials, 2012, 24(3): 536–542

Dong H, Brennan J D. Tailoring the properties of sub-3 µm silica core–shell particles prepared by a multilayer-by-multilayer process. Journal of Colloid and Interface Science, 2015, 437: 50–57

Chen Y, Chen H, Guo L, et al. Hollow/rattle-type mesoporous nanostructures by a structural difference-based selective etching strategy. ACS Nano, 2010, 4(1): 529–539

Huang T T, Geng T, Akin D, et al. Micro-assembly of functionalized particulate monolayer on C18-derivatized SiO2 surfaces. Biotechnology and Bioengineering, 2003, 83(4): 416–427

Sun S, Zhang X, Han Q, et al. Preparation and retention mechanism exploration of mesostructured cellular foam silica as stationary phase for high performance liquid chromatography. Talanta, 2016, 149: 187–193

Wang R, Tang J, Liu J, et al. Preparation of Ag@SiO2 dispersion in different solvents and investigation of its optical properties. Journal of Dispersion Science and Technology, 2011, 32(4): 532–537

Wang W, Gu B, Liang L. Effect of surfactants on the formation, morphology, and surface property of synthesized SiO2 nanoparticles. Journal of Dispersion Science and Technology, 2005, 25(5): 593–601

Iyer R, Suin S, Shrivastava N K, et al. Compatibilization mechanism of nanoclay in immiscible PS/PMMA blend using unmodified nanoclay. Polymer-Plastics Technology and Engineering, 2013, 52(5): 514–524

Liu P. Facile preparation of monodispersed core/shell zinc oxide@polystyrene (ZnO@PS) nanoparticles via soapless seeded microemulsion polymerization. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2006, 291(1–3): 155–161

Gemici Z, Shimomura H, Cohen R E, et al. Hydrothermal treatment of nanoparticle thin films for enhanced mechanical durability. Langmuir, 2008, 24(5): 2168–2177

Blue L E, Jorgenson JW. 1.1 µm superficially porous particles for liquid chromatography. Part I: synthesis and particle structure characterization. Journal of Chromatography A, 2011, 1218(44): 7989–7995

Dafinone M I, Feng G, Brugarolas T, et al. Mechanical reinforcement of nanoparticle thin films using atomic layer deposition. ACS Nano, 2011, 5(6): 5078–5087

Acknowledgements

This project was supported by the National Natural Science Foundation of China (Grant No. 51406109).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wei, X., Gong, C., Chen, X. et al. Preparation of porous hollow silica spheres via a layer-by-layer process and the chromatographic performance. Front. Mater. Sci. 11, 33–41 (2017). https://doi.org/10.1007/s11706-017-0366-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11706-017-0366-z