Abstract

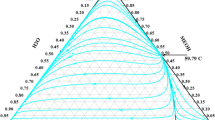

Methyl acetate is considered low toxicity volatile solvent produced either as a by-product during methanol carbonylation or via acetic acid esterification with methanol. In both cases, pure methyl acetate has to be isolated from the reaction mixture. Simulation of methyl acetate separation from its mixture with methanol by extraction distillation was carried out in ASPEN + software. In total three case studies were assumed using two different extraction solvents and two solvent regeneration strategies. In case A, novel extraction solvent 1-ethyl-3-methylimidazolium trifluoromethanesulfonate ionic liquid, was considered. Raw material separation was achieved in an extraction distillation column while the solvent regeneration was accomplished in a second distillation column in this case. In case study B, the same extraction solvent was used; however, its regeneration was carried out in a single-effect evaporator. Dimethyl sulfoxide was the second extraction solvent selected. Its use in methyl acetate-methanol separation is presented in case study C. As high purity of dimethyl sulfoxide was required for the methyl acetate-methanol azeotrope breaking, its regeneration was carried out in the second distillation column only. To simulate the ternary methyl acetate–methanol–extraction solvent mixtures separation, vapor–liquid equilibrium was predicted based on the NRTL equation. Further, unknown properties of the considered ionic liquid and variation of these properties with temperature were predicted and introduced into the ASPEN + components properties database. Based on these data, optimum operation parameters of the respective separation equipment were established. In all case studies, the same condition had to be fulfilled, namely minimum methyl acetate content in the distillate from the extraction distillation column of 99.5mol-%. Results of simulations using the respective optimum operation parameters were employed in the economic evaluation of the three separation unit designs studied. It was found that the least energy-demanding design corresponds to the case study B in terms of both capital as well as operation expenses.

Similar content being viewed by others

References

Agreda V H, Partin L R, Heise W H. High-purity methyl acetate via reactive distillation. Chemical Engineering Progress, 1990, 86(2): 40–46

Huss R S, Chen F R, Malone M F, Doherty M F. Reactive distillation for methyl acetate production. Computers & Chemical Engineering, 2003, 27(12): 1855–1866

Giwa A. Methyl acetate reactive distillation process modeling, simulation and optimization using ASPEN Plus. Journal of Engineering and Applied Sciences (Asian Research Publishing Network), 2013, 8(5): 386–392

Rohde C, Marr R, Siebenhofer M. Investigation of methyl acetate production by reactive extraction. In: Proceedings of the AIChE Annual Meeting 2004. Austin: AIChE, 2004, 5113–5118

Lux S, Winkler T, Siebenhofer M. Synthesis and isolation of methyl acetate through heterogeneous catalysis with liquid–liquid extraction. Industrial & Engineering Chemistry Research, 2010, 49(21): 10274–10278

Cao Y J, Li M, Wang Y, Zhao T R, Li X, Zhu Z Y, Wang Y L. Effect of feed temperature on economics and controllability of pressureswing distillation for separating binary azeotrope. Chemical Engineering and Processing: Process Intensification, 2016, 110: 160–171

Berg L, Yeh A I. The separation of methyl acetate from methanol by extractive distillation. Chemical Engineering Communications, 1984, 30(1–2): 113–117

Lei Z G, Li C Y, Chen B H. Extractive distillation: A review. Separation and Purification Reviews, 2003, 32(2): 121–213

Mahdi T, Ahmad A, Nasef M M, Ripin A. State-of-the-art technologies for separation of azeotropic mixtures. Separation and Purification Reviews, 2015, 44(4): 308–330

Schuur B. Selection and design of ionic liquids as solvents in extractive distillation and extractive processes. Chemical Papers, 2015, 69(2): 245–253

Jongmans M T G, Hermens E, Raijmakers M, Maassen J I W, Schuur B, de Haan A B. Conceptual process design of extractive distillation processes for ethylbenzene/styrene separation. Chemical Engineering Research & Design, 2012, 90(12): 2086–2100

Jongmans M T G, Trampé J, Schuur B, de Haan A B. Solute recovery from ionic liquids: A conceptual design study for recovery of styrene monomer from [4-mebupy][BF4]. Chemical Engineering and Processing: Process Intensification, 2013, 70: 148–161

Li G Z, Bai P. New operation strategy for separation of ethanolwater by extractive distillation. Industrial & Engineering Chemistry Research, 2012, 51(6): 2723–2729

Quijada-Maldonado E, Aelmans T A M, Meindersma G W, de Haan A B. Pilot plant validation of a rate-based extractive distillation model for water–ethanol separation with the ionic liquid [emim][DCA] as solvent. Chemical Engineering Journal, 2013, 223: 287–297

Gutierrez H J P. Extractive distillation with ionic liquids as solvents: Selection and conceptual process design. Dissertation for the Doctoral Degree. Eindhoven: Eindhoven University of Technology, 2013, 137–139

Meindersma G W, Quijada-Maldonado E, Jongmans M, de Haan A B. Extractive distillation with ionic liquids: Pilot plant experiments and conceptual process design. In: Ionic Liquids for Better Separation Processes. Berlin: Springer, 2016, 11–38

Dhanalakshmi J, Sai P S T, Balakrishnan A R. Study of ionic liquids as entrainers for the separation of methyl acetate–methanol and ethyl acetate–ethanol systems using the COSMO-RS model. Industrial & Engineering Chemistry Research, 2013, 52(46): 16396–16405

Zhang Z G, Hu A G, Zhang T, Zhang Q Q, SunMY, Sun D Z, LiW X. Separation of methyl acetate + methanol azeotropic mixture using ionic liquids as entrainers. Fluid Phase Equilibria, 2015, 401: 1–8

Orchillés A V, Miguel P J, Vercher E, Martínez-Andreu A. Isobaric vapor–liquid equilibria for methyl acetate + methanol + 1-ethyl-3-methylimidazolium trifluoromethanesulfonate at 100 kPa. Journal of Chemical & Engineering Data, 2007, 52(3): 915–920

Cai J L, Cui X B, Zhang Y, Li R, Feng T Y. Vapor–liquid equilibrium and liquid–liquid equilibrium of methyl acetate + methanol + 1-ethyl-3-methylimidazolium acetate. Journal of Chemical & Engineering Data, 2011, 56(2): 282–287

Cai J L, Cui X B, Zhang Y, Li R, Feng T Y. Isobaric vapor liquid equilibrium for methanol + methyl acetate + 1-octyl-3-methylimidazolium hexafluorophosphate at 101.3 kPa. Journal of Chemical & Engineering Data, 2011, 56(2): 2884–2888

Matsuda H, Tochigi K, Liebert V, Gmehling J. Vapor–liquid equilibria of ternary systems with 1-ethyl-3-methylimidazolium ethyl sulfate using headspace gas chromatography. Fluid Phase Equilibria, 2011, 307(2): 197–201

Dohnal V, Baránková E, Blahut A. Separation of methyl acetate + methanol azeotropic mixture using ionic liquid entrainers. Chemical Engineering Journal, 2014, 237: 199–208

Zhang Z G, Hu A G, Zhang T, Zhang Q Q, Yang Z Q, Li W X. Isobaric vapor–liquid equilibrium for methyl acetate + methanol system containing different ionic liquids at 101.3 kPa. Fluid Phase Equilibria, 2016, 408: 20–26

Cao J, Yu G G, Chen X C, Abdeltawab A A, Al-Enizi A M. Determination of vapor–liquid equilibrium of methyl acetate + methanol + 1-alkyl-3-methylimidazolium dialkylphosphates at 101.3 kPa. Journal of Chemical & Engineering Data, 2017, 62(2): 816–824

Zhang X M, Liu H P, Liu Y X, Jian C G, Wang W. Experimental isobaric vapor–liquid equilibrium for the binary and ternary systems with methanol, methyl acetate and dimethyl sulfoxide at 101.3 kPa. Fluid Phase Equilibria, 2016, 408: 52–57

Hsieh C T, Lee M J, Lin H M. Vapor–liquid–liquid equilibria for aqueous systems with methyl acetate, methyl propionate, and methanol. Industrial & Engineering Chemistry Research, 2008, 47 (20): 7927–7933

Crawford A G, Edwards G, Lindsay D S. The ternary system, methanol–methyl acetate–water. Journal of the Chemical Society, 1949: 1054–1058

Gmehling J, Onken U. Vapor–Liquid Equilibrium Data Collection. Chemistry Data Series, Vol. I, Part 1. Frankfurt/Main: DECHEMA, 1977, 37–76, 258–264

Pereiro A B, Araújo J M M, Esperança J M S S, Marrucho I M, Rebelo L P N. Ionic liquids in separations of azeotropic systems—A review. Journal of Chemical Thermodynamics, 2012, 46: 2–28

Rogers R D, Seddon K R. Ionic liquids—solvents of the future? Science, 2003, 302(5646): 792–793

Huddleston J G, Visser A E, ReichertWM,Willauer H D, Broker G A, Rogers R D. Characterization and comparison of hydrophilic and hydrophobic room temperature ionic liquids incorporating the imidazolium cation. Green Chemistry, 2001, 3(4): 156–164

Humphrey J L, Keller G E II. Separation Process Technology. New York: McGraw-Hill, 1997, 1

Blahušiak M, Kiss A A, Babic K, Kersten S R A, Bargeman G, Schuur B. Insights into the selection and design of fluid separation processes. Separation and Purification Technology, 2018, 194: 301–318

Steltenpohl P, Graczová E. Optimization of extraction solvent-to-feed ratio: Aqueous ethanol mixture separation using [TDTHP][NTf2] ionic liquid. Chemical Engineering Research & Design, 2017, 121: 200–206

de Riva J, Ferro V R, Moreno D, Diaz I, Palomar J. Aspen Plus supported conceptual design of the aromatic–aliphatic separation from low aromatic content naphtha using 4-methyl-N-butylpyridinium tetrafluoroborate ionic liquid. Fuel Processing Technology, 2016, 146: 29–38

Larriba M, de Riva J, Navarro P, Moreno D, Delgado-Mellado N, García J, Ferro V R, Rodríguez F, Palomar J. COSMO-based/Aspen Plus process simulation of the aromatic extraction from pyrolysis gasoline using the {[4empy][NTf2] + [emim][DCA]} ionic liquid mixture. Separation and Purification Technology, 2018, 190: 211–227

Graczová E, Dobcsányi D, Steltenpohl P. Separation of methyl acetate–methanol azeotropic mixture using 1-ethyl-3-methylimidazolium trifluoromethanesulfonate. Chemical Engineering Transactions, 2017, 61: 1183–1188

Boston J F, Sullivan S L Jr. A new class of solution methods for multicomponent, multistage separation processes. Canadian Journal of Chemical Engineering, 1974, 52(1): 52–63

Seader J D, Henley E J, Roper D K. Separation Process Principles. 3rd ed. New Jersey: Wiley, 2010, 400–412

Renon H, Prausnitz J M. Local compositions in thermodynamic excess functions for liquid mixtures. AIChE Journal. American Institute of Chemical Engineers, 1968, 14(1): 135–144

Valderrama J O, Forero L A, Rojas R E. Critical properties and normal boiling temperature of ionic liquids. Update and a new consistency test. Industrial & Engineering Chemistry Research, 2012, 51(22): 7838–7844

Papari M M, Amighi S, Kiani M, Mohammad-Aghaie D, Haghighi B. Modification of a statistical mechanically-based equation of state: Application to ionic liquids. Journal of Molecular Liquids, 2012, 175: 61–66

Zhang S J, Lu X M, Zhou Q, Li X H, Zhang X P, Li S C. Ionic liquids. Physicochemical properties. Amsterdam: Elsevier, 2009, 47

Zaitsau D H, Kabo G J, Strechan A A, Paulechka Y U, Tschersich A, Verevkin S P, Heintz A. Experimental vapor pressures of 1-alkyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imides and a correlation scheme for estimation of vaporization enthalpies of ionic liquids. Journal of Physical Chemistry A, 2006, 110(22): 7303–7306

Joback K G, Reid R C. Estimation of pure-component properties from group-contributions. Chemical Engineering Communications, 1987, 57(1-6): 233–243

Retrieved from the website of Alibaba (methyl-acetate), January 10, 2018

Retrieved from the website of Intratec (methanol), January 10, 2018

Retrieved from the website of Alibaba (DMSO), January 10, 2018

Acknowledgements

This work was supported by the Research and Development Assistance Agency APVV (APVV-0858-12).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Graczová, E., Šulgan, B., Barabas, S. et al. Methyl acetate–methanol mixture separation by extractive distillation: Economic aspects. Front. Chem. Sci. Eng. 12, 670–682 (2018). https://doi.org/10.1007/s11705-018-1769-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-018-1769-9