Abstract

Hydrogen is considered as the main energy genesis of the future. Many applications have been considered for the use of hydrogen as an energy source, especially in the polymer electrolyte membrane fuel cell (PEMFC). Ethanol steam reforming (ESR) is considered to be the most viable technology, because ethanol can be produced from a bio-refinery which can be easily distributed and controlled. The kinetics of ESR have been studied based on different noble metals as well as non-noble metals using supporters in the form of metal oxides, mixed metal oxides, spinel, pervoskite, hydrotalcite, etc. The Eley–Rideal (ER) mechanism and the Langamuir–Hinshelwood–Hougen–Watson (LHHW) mechanism have been used to express the kinetics of ESR. Different catalysts will follow different types of kinetics depending on the reaction path and the kind of model preferred for the development of the kinetics. LHHW mechanism is preferred over the ER mechanism due to its accuracy and the highest activation energy associated with it. This study reviews the generalized mechanistic kinetics for the ESR using fixed bed reactor to produce hydrogen.

Similar content being viewed by others

Abbreviations

- AAD:

-

Average absolute deviation

- ER:

-

Eley–Rideal

- ESR:

-

Ethanol steam reforming

- LHHW:

-

Langmuir–Hinshelwood–Hougen–Watson

- RDS:

-

Rate determining step

- WGS:

-

Water gas shift

- \(\Delta H\) :

-

Heat of adsorption

- \(C\) :

-

Concentration of reaction species

- \(C_{\text{T}}\) :

-

Concentration of active sites

- \(E_{\text{a}}\) :

-

Activation energy

- \(F\) :

-

Molar flow rate

- \(k\) :

-

Kinetic rate constant

- \(K\) :

-

Adsorption constant for species or Equilibrium constant of reaction

- \(P\) :

-

Partial pressure of reaction species

- \(R\) :

-

Universal gas constant

- \(r\) :

-

Rate of reaction

- T :

-

Temperature

- W :

-

Weight of the catalyst

- X :

-

Conversion

References

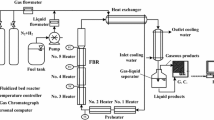

Aboudheir A, Akande A, Idem R, Dalai A (2006) Experimental studies and comprehensive reactor modelling of hydrogen production by the catalytic reforming of crude ethanol in a packed bed tubular reactor over a Ni/Al2O3 catalyst. Int J Hydrog Energy 31:752–761. https://doi.org/10.1016/j.ijhydene.2005.06.020

Akande A, Idem R, Dalai A (2005) Synthesis, characterisation and performance evaluation of Ni/Al2O3 catalysts for reforming of crude ethanol for hydrogen production. Appl Catal A 287:159–175. https://doi.org/10.1016/j.apcata.2005.03.046

Akande A, Aboudheir A, Idem R, Dalai A (2006) Kinetic modelling of hydrogen production by the catalytic reforming of crude ethanol over co-precipitated Ni-Al2O3 catalyst in a packed bed tubular reactor. Int J Hydrog Energy 31:1707–1715. https://doi.org/10.1016/j.ijhydene.2006.01.001

Akpan E, Akande A, Aboudheir A, Ibrahim H, Idem R (2007) Experimental, kinetic and 2-D reactor modelling for simulation of the production of hydrogen by the catalytic reforming of concentrated crude ethanol over a Ni-based commercial catalyst in a packed bed tubular reactor. Chem Eng Sci 62:3112–3126. https://doi.org/10.1016/j.ces.2007.03.006

Aupretre F, Descorme C, Duprez D (2002) Bio-ethanol catalytic steam reforming over supported metal oxide. Catal Commun 3:263–267. https://doi.org/10.1016/S1566-7367(02)00118-8

Aupretre F, Descrome C, Duprez D, Casanave D, Uzio D (2005) Ethanol steam reforming over MgxNi1-xAl2O3 spinel oxide based Rh catalysts. J Catal 233:464–477. https://doi.org/10.1016/j.jcat.2005.05.007

Bshish A, Yaakob Z, Narayanan B, Ramakrishnan R, Ebshish A (2011) Steam reforming of ethanol for hydrogen production. Chem Pap 65(3):251–266. https://doi.org/10.2478/s11696-010-0100-0

Cavallaro S, Chiodo V, Freni S, Mondello N, Frusteri F (2003a) Performance of Rh/Al2O3 catalyst in the steam reforming of ethanol: H2 production for MCFC. Appl Catal A 249:119–128. https://doi.org/10.1016/S0926-860X(03)00189-3

Cavallaro S, Chiodo V, Vita A, Ferni S (2003b) Hydrogen production by auto-thermal reforming of ethanol on Rh/Al2O3 catalyst. J Power Sources 123:10–16. https://doi.org/10.1016/S0378-7753(03)00437-3

Chen CC, Tseng HH, Lin YL, Chen HW (2017) Hydrogen production and carbon dioxide enrichment from ethanol steam reforming followed by water gas shift reaction. J Clean Prod 162:1430–1441. https://doi.org/10.1016/j.jclepro.2017.06.149

Comas J, Marino F, Lamborde M, Amadeo N (2004) Bio-ethanol steam reforming on Ni/Al2O3 catalyst. Chem Eng J 98:61–68. https://doi.org/10.1016/S1385-8947(03)00186-4

Comas J, Dieuzeide L, Baronetti G, Laborde M, Amadeo N (2006) Methane steam reforming and ethanol steam reforming using a Ni(II)–Al(III) catalyst prepared from lamellar double hydroxides. Chem Eng J 118:11–15. https://doi.org/10.1016/j.cej.2006.01.003

Compagnoni M, Tripodi A, Rosseti I (2017) Parametric study and kinetic testing for ethanol steam reforming. Appl Catal B Environ 203:899–909. https://doi.org/10.1016/j.apcatb.2016.11.002

Das D, Veziroglu TN (2001) Hydrogen production by biological processes: a survey of Literature. Int J Hydrog Energy 26:13–28. https://doi.org/10.1016/S0360-3199(00)00058-6

Dehkordi KT, Hormozi F, Jahangiri M (2016) Using conical reactor to improve efficiency of ethanol steam reforming. Int J Hydrog Energy 41:17084–17092. https://doi.org/10.1016/j.ijhydene.2016.07.040

De-Souza M, Zanin GM, Moraes FF (2002) Parametric study of hydrogen production from ethanol steam reforming in a membrane microreactor. Braz J Chem Eng 30(02):355–367. https://doi.org/10.1590/S0104-66322013000200013

Diagne C, Idriss H, Kiennemann A (2008) Hydrogen production by ethanol reforming over Rh/CeO2–ZrO2 catalysts. Catal Commun 3(12):565–571. https://doi.org/10.1016/s1566-7367(02)00226-1

Dobosz J, Malecka M, Zawadzki M (2018) Hydrogen generation via ethanol steam reforming over Co/HAp catalysts. J Energy Inst 91:411–423. https://doi.org/10.1016/j.joei.2017.02.001

Domínguez M, Cristiano G, López E, Llorca J (2011) Ethanol steam reforming over cobalt talc in a plate microreactor. Chem Eng J 176–177:280–285. https://doi.org/10.1016/j.cej.2011.03.087

Dou B, Zhang H, Cui G, Wang Z, Jiang B, Wang K, Chen H, Xu Y (2018) Hydrogen production by sorption-enhanced chemical looping steam reforming of ethanol in an alternating fixed-bed reactor: sorbent to catalyst ratio dependencies. Energy Convers Manag 155:243–252. https://doi.org/10.1016/j.enconman.2017.10.075

Espinal R, Anzola A, Adrover E, Roig M, Chimentao R, Medina F (2014) Durable ethanol steam reforming in a catalytic membrane reactor at moderate temperature over cobalt hydrotalcite. Int J Hydrog Energy 39:10902–10910. https://doi.org/10.1016/j.ijhydene.2014.05.127

Falco MD (2008) Pd-based membrane steam reformers: a simulation study of reactor performance. Int J Hydrog Energy 33:3036–3040. https://doi.org/10.1016/j.ijhydene.2008.03.006

Fatma SB, Aksoylu AE, Osnan I (2008) Steam reforming of ethanol over Pt/Ni Catalyst. Catal Today 138:183–186. https://doi.org/10.1016/j.apcatb.2010.11.030

Fatsikostas AN, Verykios XE (2004) Reaction network of steam reforming of ethanol over Ni-based catalysts. J Catal 225:439–452. https://doi.org/10.1016/j.jcat.2004.04.034

Fierro V, Akdim O, Mirodatos C (2003) On-board hydrogen production in a hybrid electric vehicle by bio-ethanol oxidative steam reforming over Ni and noble metal-based catalysts. Green Chem 5:20–24. https://doi.org/10.1039/b208201m

Froment GF, Bischoff KB (1990) Chemical reactor analysis and design. Wiley Inc., New York

Gallucci F, Falco MD, Tosti S, Marrelli L, Basile A (2008) Ethanol steam reforming in a dense Pd–Ag membrane reactor: a modelling work. Comparison with the traditional system. Int J Hydrog Energy 33:644–651. https://doi.org/10.1016/j.ijhydene.2007.10.039

Galvita VV, Belyaev VD, Semikolenov VA, Tsiakaras P, Frumin A, Sobyanin VA (2002) Ethanol decomposition over Pd-Based Catalyst in the presence of steam. React Kinet Catal Lett 76(2):343–351. https://doi.org/10.1023/a:1016500431269

Garcia EY, Laborde MA (1991) Hydrogen production by the steam reforming of ethanol: thermodynamic analysis. Int J Hydrog Energy 16(5):307–312. https://doi.org/10.1016/0360-3199(91)90166-G

Ghirardi ML, Zhang L, Lee JW, Flynn T, Seibert M, Greenbaum E, Melis A (2000) Microalgae: a green source of renewable H2. Trends Biotechnol 18:506–511. https://doi.org/10.1016/S0167-7799(00)01511-0

Goerke O, Pfeifer P, Schubert P (2004) Water gas shift reaction and selective oxidation of CO in microreactors. Appl Catal A 263(1):11–18. https://doi.org/10.1016/j.apcata.2003.11.036

Graschinsky C, Laborde M, Amadeo N, Valant A (2010) Ethanol steam reforming over Rh (1%) MgAl2O4/Al2O3: a kinetic study. Ind Eng Chem Res 49:12383–12389. https://doi.org/10.1021/ie101284k

Haryanto A, Fernando S, Murali N, Adhikari S (2005) Current status of hydrogen production techniques by steam reforming of ethanol: review. Energy Fuels 19:2098–2106. https://doi.org/10.1021/ef0500538

Hedayati A, Corre LO, Lacamere B, Llorca J (2016) Experimental and exergy evaluation of ethanol catalytic steam reforming in a membrane reactor. Catal Today 268:68–78. https://doi.org/10.1016/j.cattod.2016.01.058

Jordi L, Narcis H, Joaquim S, Pilar R (2002) Efficient production of hydrogen over supported Cobalt catalyst from ethanol steam reforming. J Catal 209:306–317. https://doi.org/10.1006/jcat.2002.3643

Juan-Juan J, Roman-Martinez MC, Illan-Gomez MJ (2004) Catalytic activity and characterization of Ni/Al2O3 and Ni/Al2O3 catalysts for CO2 methane reforming. Appl Catal A 264:169–174. https://doi.org/10.1016/j.apcata.2003.12.040

Kaddouri A, Mazzocchia C (2004) A study of the influence of the synthesis conditions upon the catalytic properties of Co/SiO2 or Co/Al2O3 catalysts used for ethanol steam reforming. Catal Commun 5(6):339–345. https://doi.org/10.1016/j.catcom.2004.03.008

Levin DB, Pitt L, Love M (2004) Biohydrogen production: prospects and limitations to practical application. Int J Hydrog Energy 29:173–185. https://doi.org/10.1016/S0360-3199(03)00094-6

Li T, Zhang J, Xie X, Yin X, An X (2015) Montmorillonite-supported Ni nanoparticles for efficient hydrogen production from ethanol steam reforming. Fuel 143:55–62. https://doi.org/10.1016/j.fuel.2014.11.033

Li L, Tang D, Song Y, Jiang B, Zhang Q (2018) Hydrogen production from ethanol steam reforming on Ni-Ce/MMT catalysts. Energy 149:937–943. https://doi.org/10.1016/j.energy.2018.02.116

Liguras DK, Kondarides DI, Verykios XE (2003) Production of hydrogen for fuel cells by steam reforming of ethanol over supported noble metal catalysts. Appl Catal B 43:345–354. https://doi.org/10.1016/s0926-3373(02)00327-2

Llera I, Mas V, Bergamini ML, Laborde M, Amadeo N (2012) Bio-ethanol steam reforming on Ni based catalyst. Kinetic study. Chem Eng Sci 71:356–366. https://doi.org/10.1016/j.ces.2011.12.018

Llorca J, Homs N, Sales J, Piscina R (2002) Efficient production of hydrogen over supported Cobalt catalyst from steam reforming. J Catal 209:306–317. https://doi.org/10.1006/jcat.2002.3643

Lulianelli A, Dalena F, Basile A (2017) Chapter-7—steam reforming, preferential oxidation and autothermal reforming of ethanol for hydrogen production in membrane reactors. Ethanol. https://doi.org/10.1016/b978-0-12-811458-2.00007-9

Ma R, Castro-Dominguez B, Mardilovich IP, Dixon AG, Ma YH (2016) Experimental and simulation studies of the production of renewable hydrogen through ethanol steam reforming in a large-scale catalytic membrane reactor. Chem Eng J 303:302–313. https://doi.org/10.1016/j.cej.2016.06.021

Ma R, Dominguez-Castro B, Dixon AG, Ma YH (2018) CFD study of heat and mass transfer in ethanol steam reforming in a catalytic membrane reactor. Int J Hydrog Energy 43:7662–7674. https://doi.org/10.1016/j.ijhydene.2017.08.173

Marcelo S, Batista A, Rudya K, Santos A, Elisabete M, Assaf A, José M, Assaf B, Edson A, Ticianelli A (2004) High efficiency steam reforming of ethanol by cobalt-based catalysts. J Power Sources 134:27–32. https://doi.org/10.1016/j.jpowsour.2004.01.052

Marino F, Boveri M, Baronetti G, Laborde M (2004) Hydrogen production via catalytic gasification of ethanol. A mechanism proposal over copper-nickel catalysts. Int J Hydrog Energy 29:67–71. https://doi.org/10.1016/S0360-3199(03)00052-1

Mas V, Kipreos R, Amadeo N, Laborde M (2006) Thermodynamic analysis of ethanol/water system with the stoichiometric method. Int J Hydrog Energy 31:21–28. https://doi.org/10.1016/j.ijhydene.2005.04.004

Mas V, Bergamini ML, Baronetti G, Amadeo N, Laborde M (2008) A kinetic study of ethanol steam reforming using a nickel based catalyst. Top Catal 51:39–48. https://doi.org/10.1007/s11244-008-9123-y

Mathure P, Ganguly S, Patwardhan A, Saha RK (2007) Steam reforming of ethanol using a commercial nickel-based catalyst. Ind Eng Chem Res 46:8471–8479. https://doi.org/10.1021/ie070321k

Montero C, Remiro A, Benito LP, Bibao J, Gayubo AG (2018) Optimum operating conditions in ethanol steam reforming over a Ni/La2O3-αAl2O3 catalyst in a fluidized bed reactor. Fuel Process Tech 169:207–216. https://doi.org/10.1016/j.fuproc.2017.10.003

Morgenstern D, Fornango J (2005) Low-temperature reforming of ethanol over copper-plated Raney nickel: a new route to sustainable hydrogen for transportation. Energy Fuels 19:1708–1716. https://doi.org/10.1021/ef049692t

Peela NR, Kunzru D (2011) Steam reforming of ethanol in a microchannel reactor: kinetic study and reactor simulation. Ind Eng Chem Res 50:12881–12894. https://doi.org/10.1021/ie200084b

Reith JH, Wijffels RH, Barton H (2003) Bio-methane and biohydrogen: status and perspectives of biological methane and hydrogen production. Dutch Biological Hydrogen Foundation, Petten, p 166

Rossetti I, Compagnoni M, Torli M (2015) Process simulation and optimization of H2 production from ethanol steam reforming and its use in fuel cells 1. Thermodynamic and kinetic analysis. Chem Eng J 281:1024–1035. https://doi.org/10.1016/j.cej.2015.08.025

Ruocco C, Meloni E, Palma V, Annaland MS, Spallina V, Gallucci F (2016) Pt–Ni based catalyst for ethanol reforming in a fluidized bed membrane reactor. Int J Hydrog Energy 41:20122–20136. https://doi.org/10.1016/j.ijhydene.2016.08.045

Sahoo DR, Vajpai S, Patel S, Pant KK (2007) Kinetic modelling of steam reforming of ethanol for the production of hydrogen over Co/Al2O3 catalyst. Chem Eng J 125:139–147. https://doi.org/10.1016/j.cej.2006.08.011

Serra M, Ocampo-Martinez C, Li M, Llorca J (2017) Model predictive control for ethanol steam reformers with membrane separation. Int J Hydrog Energy 42:1949–1961. https://doi.org/10.1016/j.ijhydene.2016.10.110

Sheng PY, Bowmaker GA, Idriss H (2004) The reaction of ethanol over Au/CeO2 catalyst. Appl Catal A 261:171–181. https://doi.org/10.1016/j.apcata.2003.10.046

Sun J, Qiu XP, Wu F, Zhu WT (2005) H2 from steam reforming of ethanol at low temperature over Ni/Y2O3, Ni/La2O3 and Ni/Al2O3 catalysts for fuel-cell application. Int J Hydrog Energy 30:437–445. https://doi.org/10.1016/j.ijhydene.2004.11.005

Tabakova T, Boccuzzi F, Manzoli M, Andreeva D (2003) FTIR study of low-temperature water-gas shift reaction on Gold/Ceria catalyst. Appl Catal A 252(2):385–397. https://doi.org/10.1016/S0926-860X(03)00493-9

Tabakova T, Boccuzzi F, Manzoli M, Sobczak JW, Idakiev VV, Andreeva D (2004) Effect of synthesis procedure on the low-temperature WGS activity of Au/Ceria Catalysts. Appl Catal B 49(2):73–81. https://doi.org/10.1016/j.apcatb.2003.11.014

Vaidya PD, Rodrigues AE (2006) Kinetics of steam reforming of ethanol over the Ru/Al2O3 catalyst. Ind Eng Chem Res 45:6614–6618. https://doi.org/10.1021/ie051342m

Vizcaino A, Arena P, Baronetti G, Carrero A, Calles J, Laborde M, Amadeo N (2008) Ethanol steam reforming on Ni/Al2O3 catalysts: effect of Mg addition. Int J Hydrog Energy 33:3489–3492. https://doi.org/10.1016/j.ijhydene.2007.12.012

Wu C, Dupont V, Nahil AM, Dou B, Chen H, William PT (2017) Investigation of Ni/SiO2 catalysts prepared at different conditions for hydrogen production from ethanol steam reforming. J Energy Inst 90:276–284. https://doi.org/10.1016/j.joei.2016.01.002

Zhang Q, Ling Guo, Zheng X, Xing M, Hao Z (2018) Insight into the reaction mechanism of ethanol steam reforming catalysed by Co–Mo6S8. Mol Phys. https://doi.org/10.1080/00268976.2018.1521011

Acknowledgements

The authors would like to thank Prof. Santosh Kumar Gupta of our department for his inspiring guidance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Compliance with ethical standards

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Punase, K.D., Rao, N. & Vijay, P. A review on mechanistic kinetic models of ethanol steam reforming for hydrogen production using a fixed bed reactor. Chem. Pap. 73, 1027–1042 (2019). https://doi.org/10.1007/s11696-018-00678-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-018-00678-6