Abstract

This work focuses on the application of polymer inclusion membrane (PIM) with tricaprylmethylammonium thiosalicylate, [A336][TS] (TOMATS), a thiol-containing task-specific ionic liquid for the transport of Pd(II) ions from aqueous solutions. 0.3 M thiourea in 0.1 M hydrochloric acid was found the most effective stripping phase in the transport of Pd(II) from membrane phase containing TOMATS. Separation of Pd(II) ions was also carried out from hydrochloric acid solution containing Pt(IV), Fe(III), Ni(II), and Mn(II). Pd(II) ions were preferably transported in the presence of these metal ions. The separation coefficients followed the order: S Pd/Pt < S Pd/Fe < S Pd/Ni < S Pd/Mn. [A336][TS] proved to be an excellent ion carrier for Pd(II) from hydrochloric acid solution. The results also showed that transport efficiency of the PIM was reproducible and it can be useful for the development of the simple and highly effective method of Pd(II) recovery from leach liquor of spent catalysts.

Similar content being viewed by others

Introduction

Ionic liquids (ILs) can be regarded as the alternative extractants/carriers of metal ions, inorganic acids, and organic compounds. These compounds show a number of important physicochemical properties such as negligible vapor pressure, thermal stability up to 300 °C, tunable viscosity, non-flammability, and excellent extractability for a variety of organic compounds and metal ions (Turgut et al. 2017; Mahandra et al. 2017; Rout et al. 2016; Baczynska et al. 2016; Rzelewska et al. 2016a, b; Pospiech and Kujawski 2015; Martak and Schlosser 2006). ILs are salts containing organic cation and anion (organic or inorganic) and their melting points are usually below 100 °C (Eyupoglu and Polat 2015). However, if the melting point is below room temperature, they are defined as room temperature ionic liquids (RTILs) (Turgut et al. 2017). Physicochemical properties of these compounds can be easily modified by changing an anion or a cation depending on aim of application (as solvent, extractant/carrier, reaction medium, etc.) (Turgut et al. 2017). This is very important property, and therefore, these ILs are of the great interest.

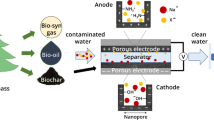

ILs can also be used in synthesis of polymer inclusion membranes (PIM) which are the type of the liquid membranes. Membrane processes are the important separation techniques and are used for removal of precious or hazardous metals from different sources (Eyupoglu and Kumbasar 2015). Transport of metal ions from aqueous solutions through polymer membrane containing the selective ion carrier is very attractive and economical compared to the solvent extraction with the high capital investment, higher organic solvent/extractant consumption, and two-step operation (extraction and stripping) (Eyupoglu et al. 2015). In the membrane process, substance is transferred from the source phase through PIM into the stripping phase within one-step operation. Moreover, the consumption of the chemicals is very low.

However, transport across PIM is not used in industry because of the limitations regarding the possibility of the loss of carrier from membrane phase into aqueous solutions during process. Adapting this type of liquids, membranes to the industrial conditions require many investigations. Studies in this range are very important and needed due to the possibility to obtain the high selectivity of transport at the very low cost. Therefore, the studies regarding stability of PIM and selectivity of the transport using membranes with different carriers are necessary. The results can be useful in the implementation of the transport through PIM in industry scale.

ILs were used as carriers in the synthesis of PIM by many researchers (Regel-Rosocka et al. 2015). Aliquat 336, [A336][Cl] (tricaprylmethylammonium chloride) is very popular and well-known compound widely used in the synthesis of PIM (Kolev et al. 2000; Blith-Raith et al. 2007; Gizli et al. 2012). Kolev et al. (2000) studied extraction of Pd(II) through PIM with Aliquat 336 as the ion carrier. In this work, the extraction of metal ions from the hydrochloric acid solutions into poly(vinyl chloride) (PVC)-based membranes containing Aliquat 336 chloride as both the extractant and the plasticizer was experimentally studied. The rate of extraction into membrane phase was considerably faster than observed previously for other metals, i.e., Au(III). The same compound was also used for separation of Ni(II) and Co(II) from 7 mol/dm3 hydrochloric acid solution through PIM (Blith-Raith et al. 2007). Regel-Rosocka and Wisniewski (2011) , Regel-Rosocka et al. (2015) and Nowak et al. (2010) studied phosphonium and ammonium quaternary salts as the extractants as well as the ion carriers of Zn(II) and Fe(II)/Fe(III). Kogelnig et al. (2011) reported application of phosphonium salt [Cyphos IL 101—trihexyl(tetradecyl)phosphonium chloride] as the carrier of Zn(II) from 5 mol/dm3 hydrochloric acid into 1 mol/dm3 sulfuric acid as the receiving phase. Guo et al. (2011) showed that Cyphos IL 104 [trihexyl(tetradecyl)phosphonium bis (2,4,4-trimethylpentyl)phosphinate] can be used as the carrier of Cr(VI) from hydrochloric acid into sodium hydroxide solution.

Kogelnig et al. (2008) synthesized task-specific ionic liquid (TSIL) containing thiol—tricaprylylmethylammonium thiosalicylate [A336][TS]. TSILs contain functional groups appended to the cation and can extract metal ions without the ion exchange. The literature review shows that this TSIL is the excellent extractant of heavy metal ions, such as Hg(II), Cu(II), Ag(I), Fe(III), Cd(II), and Pb(II) from aqueous solutions (Kogelnig et al. 2008; Egorov et al. 2010; Fisher et al. 2011).

Spent catalysts and electronic scraps are potential source of palladium (Cieszynska and Wisniewski 2012; Saternus and Fornalczyk 2013; Lee et al. 2010). Palladium is usually present in aqueous solutions along with various metals, particularly present in the leach liquor of metallic waste. The transfer of metallic species from the source solution into the receiving phase depends on the nature of the species present in the aqueous solutions. The leach solutions containing Pd(II) and Pt(IV) as well as other metal ions are very often generated during the processing of various spent materials, i.e., spent catalysts (Sarioglan 2013). Selective separation of the precious metal ions from chloride leach liquors is difficult, because these metal ions exist usually as the anionic chlorocomplexes and show similar physicochemical properties (Jha et al. 2014). Chloride leach liquors of spent automobile catalysts contain usually mixture of various metal ions such as Pd(II), Pt(IV), Fe(III), Ni(II), and Mn(II) (Lee et al. 2010). Therefore, development of a simple, efficient, economical, and environmentally friendly process for the selective separation and recovery of palladium(II) ions from acidic chloride solutions is very important. Table 1 shows examples of PIM application for Pd(II) transport from hydrochloric acid solutions across membrane with various ion carriers (including ILs) reported in the literature.

The aim of this work was to study the facilitated transport of Pd(II) ions from hydrochloric acid solutions across PIM with [A336][TS]. It is worth highlighting that plasticizer is very important component of PIM which playing a role of solvent for the carrier within the membrane phase. Moreover, plasticizer improves flexibility of membrane and permeability of metal ions (Pospiech 2014). In this work, the competitive transport of Pd(II), Pt(IV), Fe(III), Ni(II), and Mn(II) from aqueous solutions has also been investigated.

Experimental

Reagents

Inorganic chemicals, i.e., palladium(II) chloride anhydrous, (PdCl2, purity = 99%), chloroplatinic acid, (30% H2PtCl6, pure), manganese(II) chloride tetrahydrate (MnCl2·4H2O, purity = 99%), nickel(II) chloride hexahydrate (NiCl2·6H2O, purity = 99%), iron(III) chloride (FeCl3, purity = 98%), and hydrochloric acid (HCl), were of analytical grade and were purchased from POCh (Gliwice, Poland). Aqueous solutions were prepared with deionized water.

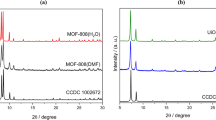

Organic reagents, i.e., cellulose triacetate (CTA) (Fluka), thiourea (POCh, Gliwice, Poland), dichloromethane (POCh, Gliwice, Poland), o-nitrophenyl octyl ether (ONPOE) (Fluka), tricaprylmethylammonium thiosalicylate, and [A336][TS] (≥95%), were supplied as reagent grade products by Sigma-Aldrich and used without further purification. The chemical structure of [A336][TS] ionic liquid is presented in Fig. 1.

Structure of TOMATS (www.sigmaaldrich.com/technical-documents)

Polymer inclusion membrane

The membranes were prepared as described in detail elsewhere (Pospiech 2015a, b). Solutions of cellulose triacetate (CTA), ion carrier ([A336][TS], TOMATS), and plasticizer, i.e., nitrophenyl octyl ether (ONPOE) in dichloromethane, were prepared. A portion of this solution was poured on a flat-bottom glass Petri dish which was kept on a leveled surface. Organic solvent was allowed to evaporate over a period of 12 h. The obtained membrane was peeled off of the Petri dish, and subsequently, it was washed with water and conditioned in distillated water before the use. The thickness of PIMs was measured using the digital ultrameter (MG-401, Elmetron).

In the preliminary experiment, the membrane containing only CTA (40 wt%) as the polymer support and ONPOE (60 wt%) as the plasticizer was prepared (PIM 1). In the next experiments, the membrane containing CTA, ONPOE, and TOMATS as the carrier was prepared and used for the investigation (PIM 2). Table 2 shows the composition of the used PIMs.

Transport experiments

Transport measurements were carried out in the experimental rig described and presented in detail elsewhere (Pospiech 2015a, b). The volumes of source and receiving phases were both equal to 100 cm3. During experiments, membrane samples with an effective membrane area of 12.56 cm2 were used. The source and receiving aqueous phases were stirred using magnetic stirrers. Aqueous phases were pumped through the membrane module at the flow rate of 50 cm3min−1, using a multichannel peristaltic pump (PP1B-05A type, Zalimp, Poland). The permeation rate of Pd(II) ions was determined by sampling of the source phase. Samples were subsequently analyzed using an atomic absorption spectrophotometer (Solaar 939, Unicam). The source phase contained 0.001 M PdCl2 in solution. To study the influence of the hydrochloric acid concentration in the source phase on palladium transport, a series of experiments was carried out at various hydrochloric acid concentrations. The single Pd(II) transport across PIM at 0.001 M metal ion concentration from aqueous source phase at varying hydrochloric acid concentrations was studied using 0.1 M HCl and 0.3 M thiourea as the receiving phase. Time of the transport process was 24 h. Table 3 shows the conditions of the respective experiments.

The kinetics of Pd(II) ions transport through the PIM can be modeled with the following equation (Pospiech 2015a, b):

where c is the metal ion concentration (M) in the source phase at a given time, c i is the initial metal ion concentration in the source phase, k is the rate constant (s−1), and t is the time of transport (s).

The value of rate constant (k) was calculated from the plot of ln(c/c i ) vs. time—Eq. (1). Experiments were run in duplicates and the rate constant value is an average from the both experiments. The value of the permeability coefficient (P) was subsequently calculated using

where V is volume of the aqueous source phase, and A is the effective area of the membrane.

The initial flux value (J i ) was subsequently calculated using

In addition, the recovery factor (RF) was determined using

The selectivity coefficient (S) was defined as the ratio of initial fluxes for M 1 and M 2 metal ions, respectively (Pospiech 2015a):

Stability of PIM

The stability of the PIM containing 40 wt% CTA, 38 wt% ONPOE, and 22 wt% TOMATS was evaluated on the basis of the initial flux values obtained from four sequential experiments in which the membrane was used under the following experimental conditions: 1 M HCl as the source phase, concentration of Pd(II) ions 0.001 M, and the receiving phase: 0.3 M thiourea in 0.1 M HCl.

Results and discussion

Kinetic of transport

The physicochemical properties of the ion carrier (e.g., density, viscosity), the cation and anion combination, as well as the presence of the sulfur in the functional group of ionic liquid are essential factors strongly influencing the extraction efficiency and transfer of metal ions from the aqueous solutions (Fisher et al. 2011). Therefore, the study of the transport of Pd(II) through PIM with TOMATS can provide important knowledge concerning the efficiency and selectivity of the separation process applying this IL as the ion carrier. Considering strong complexing properties of this ammonium ionic liquid, the high values of the recovery factor (% RF), the initial flux (J i ), and the permeability coefficient (P) should be expected.

Initially, the transport of Pd(II) ions was investigated using PIM without the ion carrier (membrane PIM1—Table 2). The results of this experiment showed that Pd(II) ions were not transported through membrane into the receiving phase. The conditions used to perform this process are shown in Table 3. In the subsequent experiments, PIM 2 membrane (Table 2) with TOMATS as the ion carrier was prepared and used. Pd(II) ions were transported from 1 M HCl solution into 0.3 M thiourea in 0.1 M HCl as the receiving phase. To calculate the k value (rate constant), a plot of ln(c/c i ) vs. time was prepared. Figure 2 shows the kinetics dependence of ln(c/c i ) vs. time for the transport of Pd(II) through the studied membrane. The results show that the ion carrier is necessary in the synthesis of the membrane. The relationship of ln(c/c i ) vs. time is linear. The rate constant of this transport process was 0.148 h−1. The recovery factor (RF) of Pd(II) after 24 h amounted to 97.6%. The results of this experiment show that the transport rate of Pd(II) is high. For instant, the rate constant of the transport of Pd(II) through PIM containing 19.9 wt% CTA, 55.2 wt% ONPOE, and 24.9 wt% Cyanex 471X was 0.138 h−1 in the similar conditions (Pospiech 2015b). As it can be seen, transport of Pd(II) across PIM with [A336][TS]—TOMATS is effective and the obtained results can be recognized as the promising ones.

Influence of hydrochloric acid concentration in the source phase

The single Pd(II) transport across PIM at 0.001 M metal ion concentration from aqueous source phases of varying hydrochloric acid concentrations was studied. Figure 3 shows the influence of HCl concentration in the source phase on the value of the initial flux (J i ). Kinetic parameters of this transport of Pd(II) are gathered in Table 4.

Effect of hydrochloric acid concentration in the source phase on the initial flux (J i ) of Pd(II). Conditions as in Fig. 2

As it can be seen from the data presented in Table 4, the rate constants and the permeability coefficients as well as the recovery factor of Pd(II) after 24 h are strongly dependent on the concentration of HCl in the source phase, especially at concentration of acid in the source phase above 3 M. To explain these transport experimental results, the contributions of formed chloride species of Pd(II) in the aqueous chloride solutions can be used. The percent molar contributions of chloride complex species for Pd(II) vs. chloride ions concentration are presented in Fig. 4. α 0 is the percent molar contribution of uncomplexed cations (i.e., Pd2+), and α 1, α 2, α 3, and α 4 are percent molar contributions of complexed ions with 1, 2, 3, and 4 ligands, respectively (i.e., PdCl+, PdCl2, PdCl3 −, and PdCl4 2−). At high chloride ion concentration, the predominant species in solution is PdCl4 2−. Probably, the transport proceeds according to a coordination salvation mechanism. Further studies are necessary to describe the transport mechanism. It was found that the permeability of process decreases slightly with the increase in hydrochloric acid concentration up to 3 M.

The results indicated that Pd(II) ions transport decreased as the acid concentration in the source phase increased. This decrease can be explained in terms of competition between the PdCl4 2− complexes and HCl to react with [A336][TS]. The similar observations during transport of Cd(II) ions from hydrochloric acid solutions through PIM with TiOAC (tri-isooactylammonium chloride) were reported by Alguacil et al. (2016). This behavior can be explained by the co-transport of hydrochloric acid at high concentration of this acid in the source phase.

Effect of thiourea concentration in 0.1 M hydrochloric acid as the receiving phase

In the next series of the experiments, the influence of the thiourea concentration in the receiving phase on the transport and recovery factor of Pd(II) has been studied. The stripping reaction at the membrane/stripping interface is very important during transport of metal ions. To analyze the effect of thiourea concentration in 0.1 M hydrochloric acid as the receiving phase on the transport of Pd(II), the aqueous solutions of thiourea were prepared and the concentration of the solution varied in the range from 0.0 to 0.5 M. The initial flux of Pd(II) increases with increase of thiourea concentration in 0.1 M HCl the receiving phase up to 0.3 M (Fig. 5).

Transport of metal ions increased and the mass flux was practical constant beyond thiourea concentration of 0.3 M. The highest initial flux (J i ) was for 0.3 M thiourea concentration in 0.1 M HCl as the receiving phase (J i = 3.2 μmol s−1 m−2). This kind of the stripping phase was also used by other researchers in liquid–liquid extraction (Swain et al. 2010) as well as in membrane system (Regel-Rosocka et al. 2015). Swain et al. (2010) studied the stripping of Pd(II) from organic phase after extraction by Alamine 300 (trioctylamine). They reported that, in the case of chloride solutions, there metal ions are stripping by a coordination–substitution reaction between thiourea (NH2)2CS and chloride ions. Regel-Rosocka et al. (2015) reported that 0.1 M thiourea and 0.5 M HCl formed the effective receiving phase for the transport of Pd(II) from aqueous chloride solutions across PIM with Cyphos IL 101.

Selectivity studies

The effect of other metal ions, including Pd(II), Pt(IV), Mn(II), Ni(II), and Fe(III) ions on the transport of Pd(II) through PIM, was also investigated. Table 5 contains the results of this study, presenting values of the rate constants (k), initial fluxes (J i ), and the selectivity coefficient (S Pd/metal) obtained during the experiments.

The results show that the initial transport fluxes of Pd(II), Pt(IV), Ni(II), and Mn(II) ions across PIM with [A336][TS] decrease in the sequence: Pd(II) > Pt > Fe(III) > Ni(II) > Mn(II). Since the selectivity coefficient values are greater than 1, this system is able to separate palladium(II) from the examined base metals.

Stability of PIM in transport process of Pd(II)

There were four repeated membrane transport experiments which used the same membrane. This membrane was taken away from the cell and washed in deionized water. The permeability coefficient of Pd(II) varied slightly after four cycles of 24 h each. In Table 6, the variation of the initial flux of Pd(II) observed during all four experiments is shown.

As it can be seen, the value of the initial flux for Pd(II) decreased slightly from 3.28 to 3.05 μmolm−2s−1. This observation confirms low tendency to leach the ion carrier from membrane matrix like in the earlier studies (Pospiech 2015a, b). Membrane with TOMATS has good stability, because the decrease in the initial flux is very small. It confirms that the rate of loss of the carrier to the aqueous phases that the membrane is in contact is also very small. In view of the high stability of the PIM in these experimental conditions, the membrane can be used for the recovery and separation of Pd(II) from acidic solutions, i.e., from leach liquor of spent catalysts.

Conclusions

Palladium(II) was recovered from hydrochloric acid solutions by transport through PIM containing 40 wt% CTA, 38 wt% ONPOE, and 22 wt% TOMATS as the ion carrier into 0.3 M thiourea in 0.1 M HCl as the receiving phase. It was found that the recovery factor (RF, %) of Pd(II) and kinetic parameters are dependent on hydrochloric acid concentration in the source phase. PIM with TOMATS was successfully used for the transport of Pd(II) ions from the aqueous solution containing Pt(IV), Fe(III), Ni(II), and Mn(II) ions. The studies proved that the application of 0.3 M thiourea in 0.1 M hydrochloric acid solution allows for an efficient transport of Pd(II). The results also revealed that the membrane separation process can be an alternative method for the selective recovery of palladium(II) from acidic chloride solutions, i.e., leach liquor of spent catalysts.

References

Alguacil FJ, Lopez FA, Garcia-Diaz I, Rodrigez O (2016) Cadmium(II) transfer using (TiOAC) ionic liquid as carrier in a smart liquid as carrier in a smart liquid membrane technology. Chem Eng Process 99:192–196. doi:10.2016/j.cep.2015.06.007

Baczynska M, Rzelewska M, Regel-Rosocka M, Wisniewski M (2016) Transport of iron ions from chloride solutions using cellulose triacetate matrix inclusion membranes with an ionic liquid carrier. Chem Paper 70:172–179. 10.1515/chempap-2015-0198

Blith-Raith AH, Paimin R, Cattrall RW, Kolev SD (2007) Separation of cobalt(II) and nickel(II) by solid phase extraction into Aliquat 336 chloride immobilized in poly(vinyl chloride). Talanta 71:419–423. doi:10.1016/j.talanta.2006.04.017

Cieszynska A, Wisniewski A (2012) Extractive recovery of palladium(II) from hydrochloric acid solutions with Cyphos IL 104. Hydrometallurgy 113–114:79–85. doi:10.1016/j.hydromet.2011.12.006

Egorov VM, Djigailo DI, Momotenko DS, Chernyshov DV, Smirnova Torocheshnikova SV, Pletnev IV (2010) Task-specific ionic liquid trioctylmethylammonium salicylate as extraction solvent for transition metal ions. Talanta 80:1177–1182. doi:10.1016/j.talanta.2009.09.003

Eyupoglu V, Kumbasar RA (2015) Extraction of Ni(II) from spent Cr-Ni electroplating bath solutions using LIX 63 and 2BDA as carriers by emulsion liquid membrane technique. J Ind Eng Chem 21:303–310. doi:10.1016/j.jiec.2014.02.037

Eyupoglu V, Polat E (2015) Evaluation of Cd(II) transport with imidazolium bromides bearing butyl and isobutyl groups as extractants from acidic iodide solutions by liquid-liquid solvent extraction. Fluid Phase Equilib 394:46–60. doi:10.1016/j.fluid.2015.03.003

Eyupoglu V, Surucu A, Kunduracioglu A (2015) Synergistic extraction of Cr(VI) from Ni(II) and Co(II) by flat sweet supported liquid membranes using TIOA and TBP as carriers. Pol J Chem Technol 17:34–42. doi:10.2478/pjct-2014-0078

Fisher L, Falta T, Koellensperger G, Stojanovic A, Kogelnig D (2011) Ionic liquids for extraction of metals and metal containing compounds from communal and industrial waste water. Water Res 45:4601–4614. doi:10.1016/j.watres.2011.06.011

Gizli N, Cinarli S, Demircioglu M (2012) Characterization of poly(vinylchloride) (PVC) based cation exchange membranes prepared with ionic liquids. Sep Purif Technol 97:96–107. doi:10.1016/j.seppur.2012.02.028

Guo L, Liu Y, Zhang C, Chen J (2011) Preparation of PVDF-based polymer inclusion membrane using ionic liquid plasticizer and Cyphos IL 104 carrier for Cr(VI) transport. J Membr Sci 372:314–321. doi:10.1016/j.memsci.2011.02.014

Jha MK, Gupta D, Lee J, Kumar V (2014) Jeong J. Solvent extraction of platinum using amine based extractants in different solutions: a review. Hydrometallurgy 142:60–69. doi:10.1016/j.hydromet.2013.11.009

Kogelnig D, Stojanovic A, Galanski M, Groessl M, Jirsa F (2008) Greener synthesis of new ammonium ionic liquids and their potential as extracting agents. Tetrahedron Lett 49:2782–2785. doi:10.1016/j.tetlet.2008.02.138

Kogelnig D, Regelsberger A, Stojanovic A, Jirsa F, Krachler R, Keppler BK (2011) A polymer inclusion membrane based on the ionic liquid trihexyl(tetradecyl)phosphonium chloride and PVC for solid–liquid extraction of Zn(II) from hydrochloric acid solution. Monatsh Chem 142:769–772. doi:10.1007/s00706-011-0530-6

Kolev SD, Sakai Y, Cattrall RW, Paimin R, Potter ID (2000) Theoretical and experimental study of palladium(II) extraction from hydrochloric acid solutions into Aliquat 336/PVC membranes. Anal Chim Acta 413:241–246

Lee JY, Raju BN, Kumar Reddy BR (2010) Solvent extraction separation and recovery of palladium and platinum from chloride leach liquors of spent automobile catalyst. Sep Purif Technol 73:213–218. doi:10.1016/j.seppur.2010.04.003

Mahandra G, Singh R, Gupta B (2017) Liquid-liquid extraction studies on Zn(II) and Cd(II) using phosphonium ionic liquid (Cyphos Il 104) and recovery of zinc from plating mud. Sep Purif Technol 177:281–292. doi:10.1016/j.sppur.2016.12.035

Martak J, Schlosser S (2006) Phosphonium ionic liquids as new, reactive extractants of lactic acid. Chem Pap 60:395–398. doi:10.2478/s11696-006-0072-2

Nowak L, Regel-Rosocka M, Marszałkowska B, Wisniewski M (2010) Removal of Zn(II) from chloride acidic solutions with hydrophobic quaternary salts. Pol J Chem Technol. 12:24–28. doi:10.2478/v10026-010-0028-8

Pospiech B (2014) Selective recovery of cobalt(II) towards lithium(I) from chloride media by transport across polymer inclusion membrane with triisooctylamine. Pol J Chem Technol 16:15–20. doi:10.2478/pict-2014-0003

Pospiech B (2015a) Studies on extraction and permeation of cadmium(II) using Cyphos IL 104 as selective extractant and ion carrier. Hydrometallurgy 154:88–94. doi:10.1016/j.hydromet.2015.04.007

Pospiech B (2015b) Highly efficient facilitated membrane transport of palladium(II) ions from hydrochloric acid solutions through plasticizer membranes with Cyanex 471X. Physicochem Probl Min Process 51:281–291. doi:10.5277/ppmp150125

Pospiech B, Kujawski W (2015) Ionic liquids as selective extractants and ion carriers of heavy metal ions from aqueous solutions utilized in extraction and membrane separation. Rev Chem Eng 31:179–191. doi:10.1515/revce-2014-0048

Regel-Rosocka M, Wisniewski M (2011) Selective removal of zinc(II) from spent pickling solutions in the presence of iron ions with phosphonium ionic liquid Cyphos IL 101. Hydrometallurgy 110:85–90. doi:10.1016/j.hydromet.2011.08.012

Regel-Rosocka M, Rzelewska M, Baczynska M, Janus M, Wisniewski M (2015) Removal of palladium(II) from aqueous chloride solutions with Cyphos phosphonium ionic liquids as metal ion carriers for liquid–liquid extraction and transport across polymer inclusion membranes. Physicochem Probl Miner Process 51:621–631. doi:10.5277/ppmp150221

Rout A, Chatterjee K, Venkatesan KA, Sahu KK, Antony MP, Rao PRV (2016) Solvent extraction of plutonizm(IV) in monoamide—ammonium ionic liquid mixture. Sep Purif Technol 159:43–49. doi:10.1016/j.seppur.2015.12.053

Rzelewska M, Baczynska M, Regel-Rosocka M, Wisniewski M (2016a) Trihexyl(tetradecyl)phosphonium bromide as extractant for Rh(III), Ru(III) and Pt(IV) from chloride solutions. Chem Pap 70:454–460

Rzelewska M, Baczynska M, Wisniewski M, Regel-Rosocka M (2016b) Phosphonium ionic liquids as extractants for recovery of ruthenium(III) from acidic aqueous solutions. Chem Pap. doi:10.1007/s11696-016-0027-1

Sarioglan S (2013) Recovery of palladium from spent activated carbon-supported palladium catalysts. Platin Metals Rev 57:289–296. doi:10.1595/147106713X663988

Saternus M, Fornalczyk A (2013) Possible ways of refining precious group metals (PGM) obtained from recycling of the used auto catalytic converters. METABK 2013 52:267–270 (UDC-UDK 669.21/.23.004.86.66.066.1)

Swain B, Jeong J, Kim SK, Lee JCh (2010) Separation of platinum and palladium from chloride solution by solvent extraction using Alamine 300. Hydrometallurgy 104:1–7. doi:10.1016/j.hydromet.2010.03.013

Turgut H, Eyupoglu V, Kumbasar R, Sisman I (2017) Alkil chain length dependent Cr(VI) transport by polymer inclusion membrane using room temperature ionic liquids as carrier and PVDF-co-HFP as polymer matrix. Sep Purif Technol 175:406–417. doi:10.1016/j.seppur.2016.11.056

Acknowledgements

The research was supported by the BS/PB-207-301/09.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Pospiech, B. Facilitated transport of palladium(II) across polymer inclusion membrane with ammonium ionic liquid as effective carrier. Chem. Pap. 72, 301–308 (2018). https://doi.org/10.1007/s11696-017-0280-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-017-0280-y