Abstract

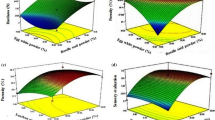

This research aimed to investigate the optimum levels of yeast β-glucan and additional water, and chilled storage time for producing chilled bread using response surface methodology. Yeast β-glucan, a natural hydrocolloid extracted from yeast cell wall, possesses not only functional properties but also human health benefits to be used in food products. A Box–Behnken design with three independent variables (yeast β-glucan, additional water, and chilled storage time) and three levels was used to develop models for the different characteristic responses. Superimposition of contour plots of the significant responses (spread ratio, crumb color L* and b* values, crumb hardness and cohesiveness, and moisture content) was performed to obtain the optimum chilled bread formula. Using the qualities of one-day-on-shelf commercial bread as a reference, the optimum chilled bread contained 0.28% yeast β-glucan and 11.69% additional water (wheat flour basis) with 4 days chilled storage. The optimum chilled bread had superior qualities to the basic formula bread at 4 days of chilled storage. The bread staling during chilling can be retarded by incorporating yeast β-glucan and additional water in the bread formula.

Similar content being viewed by others

References

V. Uygur, M. Şen, Int. J. Agric. For. Life Sci. 2, 2 (2018)

D. Altindal, N. Altindal, Int. J. Agric. For. Life Sci. 2, 2 (2018)

V. Okatan, Folia Hort. 30, 1 (2018)

R.C. Hoseney, Principles of cereal science and technology, 2nd edn. (American Association of Cereal Chemists (AACC), St. Paul, 1994), pp. 229–274

I. Mandala, D. Karabela, A. Kostaropoulos, Food Hydrocolloids. 21, 8 (2007)

A. Mohamed, P. Rayas-Duarte, J. Xu, Food Chem. 107, 1 (2008)

M.L. Martin, K.J. Zeleznak, R.C. Hoseney, Cereal Chem. 68, 5 (1991)

C.M. Rosell, J.A. Rojas, C.B. de Barber, Food Hydrocolloids. 15, 1 (2001)

M. Gómez, F. Ronda, C.A. Blanco, P.A. Caballero, A. Apesteguía, Eur. Food Res.Technol. 216, 1 (2003)

S. Thammakiti, M. Suphantharika, T. Phaesuwan, C. Verduyn, Int. J. Food Sci. Technol. 39, 1 (2004)

V. Petravić-Tominac, V. Zechner-Krpan, K. Berković, P. Galović, Z. Herceg, S. Srečec, I. Špoljarić, Food Technol. Biotechnol. 49, 1 (2011)

R. Banchathanakij, M. Suphantharika, Food Chem. 114, 1 (2009)

EFSA. (2011), https://www.efsa.europa.eu/en/efsajournal/pub/2137

Food, D. Administration, Agency Response Letter GRAS Notice No. GRN 000239. (U.S. Food and Drug Administration, 2008), https://wayback.archive-it.org/7993/20170607015213/https://www.fda.gov/downloads/Food/IngredientsPackagingLabeling/GRAS/NoticeInventory/UCM267500.pdf. Accessed 24 February 2019

S. Worrasinchai, M. Suphantharika, S. Pinjai, P. Jamnong, Food Hydrocolloids. 20, 1 (2006)

R. Santipanichwong, M. Suphantharika, Food Hydrocolloids. 21, 4 (2007)

V. Sae-kang, M. Suphantharika, Carbohydr. Polym. 65, 3 (2006)

S. Satrapai, M. Suphantharika, Carbohydr. Polym. 67, 4 (2007)

L. Wang, R.A. Miller, R.C. Hoseney, Cereal Chem. 75, 2 (1998)

L. Flander, M. Salmenkallio-Marttila, T. Suortti, K. Autio, LWT – Food Sci. Technol. 40, 5 (2007)

A. Skendi, C.G. Biliaderis, M. Papageorgiou, M.S. Izydorczyk, Food Chem. 119, 3 (2010)

M. Kinner, S. Nitschko, J. Sommeregger, A. Petrasch, G. Linsberger-Martin, H. Grausgruber et al., J. Cereal Sci. 53, 2 (2011)

P. Kittisuban, P. Ritthiruangdej, M. Suphantharika, LWT – Food Sci. Technol. 57, 2 (2014)

R. Wongsagonsup, P. Kittisuban, A. Yaowalak, M. Suphantharika, Int. Food Res. J. 22, 2 (2015)

D. Baş, İH. Boyacι, J. Food Eng. 78, 3 (2007)

R. Wang, W. Zhou, H.H. Yu, W.F. Chow, J. Sci. Food Agric. 86, 6 (2006)

A.A.C.C. International, Approved Methods of Analysis, 10th edn. (AACC International, St. Paul, 2000)

S.Y. Sim, A.A. Noor Aziah, L.H. Cheng, Food Hydrocolloids. 25, 5 (2011)

S.R. Chevallier, R. Zúñiga, A. Le-Bail, Food Bioprocess Tech. 5, 2 (2012)

T.R. Dapčević Hadnađev, L.P. Dokić, M.S. Hadnađev, M.M. Pojić, S.M. Rakita, A.M. Torbica, Food Feed Res. 40, 2 (2013)

D. Sabanis, C. Tzia, Food Bioprocess Tech. 2, 1 (2009)

A. León, E. Durán, C.B. de Barber, Z. Lebensm. −Unters. Forsch. 204, 4 (1997)

C.G. Biliaderis, M.S. Izydorczyk, O. Rattan, Food Chem. 53, 2 (1995)

E. Armero, C. Collar, Z. Lebensm. −Unters. Forsch. 204, 2 (1997)

M.E. Matos, C.M. Rosell, Eur. Food Res. Technol. 235, 1 (2012)

Acknowledgements

The authors are grateful to Thailand Research Fund through the Royal Golden Jubilee Ph.D. Program for financial support (Grant no. PHD/0205/2552). This research is also partially supported by the Center of Excellence on Agricultural Biotechnology, Science and Technology Postgraduate Education and Research Development Office, Office of Higher Education Commission, Ministry of Education (AG-BIO/PERDO-CHE).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Suwannarong, S., Wongsagonsup, R., Luangpituksa, P. et al. Optimization of yeast β-glucan and additional water levels, and chilled storage time on characteristics of chilled bread using response surface methodology. Food Measure 13, 1683–1694 (2019). https://doi.org/10.1007/s11694-019-00085-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-019-00085-9