Abstract

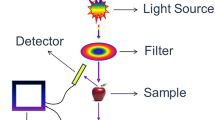

Optimum maturity at harvest is a very important determinant to ensure the final quality of the fruits. Harvesting fruits at appropriate time maintains different quality parameters such as taste, size, shape, nutritional parameters and also have longer shelf life. While as fruits picked too early or too late in season are more susceptible towards different physiological disorders as well as have very shorter shelf life. So optimal harvesting time judgement is one of the most important information for various fruit growers to optimize the yield and to decrease the on-field losses. In recent years, various rapid and reliable non-destructive sensing techniques along with different multivariate, data fusion, and chemometric algorithms have been evolved to measure the quality parameters of different fruit samples at the time of harvesting. This paper presents an extensive review on different on-field issues during harvesting of various fruits and also how these issues significantly contributes to fruit spoilage all over the world. Presented paper also consist review on different non-destructive sensing techniques (electronic nose, spectroscopy, ultrasonic, imaging etc) along with various data processing algorithms (data treatment, feature extraction, data fusion etc) used for quality assessment of different fruit cultivars. Scope of multiple non-destructive sensing techniques fusion, challenges and bottlenecks also have been explored in the context of fruit quality assessment. Various products available in global market are also reviewed based on their sensing technique, application, prediction capabilities, cost, accessibility and reliability.

Similar content being viewed by others

References

Food Loss and Food Waste (2015). http://www.fao.org/food-loss-and-food-waste/en/. Accessed 2 May 2017

India wastes Rs 440 billion on fruits and vegetables. http://www.thestatesman.com/mobi/news/27363-india-wastes-rs-440-billion-on-fruits-and-vegetables.html. Accessed 29 Nov 2013

Global food security index 2014 SPECIAL REPORT: Food loss and its intersection with food security by The Economist

J. Gustavsson, C. Cederberg, U. Sonesson, R. van Otterdijk, A. Meybeck, Global Food Losses and Food Waste: Extent Causes and Prevention.” (Food and Agriculture Organization (FAO) of the United Nations, Rome, 2011)

World Food Logistics Organization. Identification of Appropriate Postharvest Technologies for improving Market Access and Incomes for Small Horticultural Farmers in Sub-Saharan Africa and South Asia. (World Food Logistics Organization Alexandria, 2010)

A.A. Gowen et al., Hyperspectral imaging–an emerging process analytical tool for food quality and safety control. Trends Food Sci. Technol. 18(12), 590–598 (2007)

A. Loutfi et al., Electronic noses for food quality: a review. J. Food Eng. 144, 103–111 (2015)

T.S. Awad et al., Applications of ultrasound in analysis, processing and quality control of food: A review. Food Res. Int. 48(2), 410–427 (2012)

S. Khalifa, M. Komarizadeh, B. Tousi, Usage of fruit response to both force and forced vibration applied to assess fruit firmness-a review. Aust. J. Crop Sci. 5.5, 516 (2011)

Mohr, Test & Measurement Solution for Industry, home page. http://www.mohr-engineering.com/mdt-fruit-tester-texture-analyzer.php. Accessed 2 May 2017

RJL Systems, home page. https://www.rjlsystems.com/applications-of-bia/real-time-bioelectrical-impedance-analysis-experiment-4-0/. Accessed 6 May 2017

M. Soltani, R. Alimardani, M. Omid, Prediction of banana quality during ripening stage using capacitance sensing system. Aust. J. Crop Sci. 4(6), 443 (2010)

M. Aboonajmi, H. Faridi, Nondestructive quality assessment of Agro-food products. in Proceedings of the 3rd Iranian International NDT Conference, Tehran, 2016. Accessed 6 May 2017

Y-net news.com, Israeli mini-scanner tells what’s in food, drink or pills. http://www.ynetnews.com/articles/0,7340,L-4700181,00.html. Accessed 8 May 2017

K. Persaud, G. Dodd, Analysis of discrimination mechanisms in the mammalian olfactory system using a model nose. Nature 299 (5881), 352–355 (1982)

M. Peris, L. Escuder-Gilabert, A 21st century technique for food control: electronic noses. Anal. Chim. Acta 638(1), 1–15 (2009)

M.A.M. El Hadi et al., Advances in fruit aroma volatile research. Molecules 18(7), 8200–8229 (2013)

D. Holland, O. Larkov, I. Bar-Yaákov, E. Bar, A. Zax, E. Brandeis, Developmental and varietal differences in volatile ester formation and acetyl-CoA: Alcohol acetyl transferase activities in apple (Malus domestica Borkh.) fruit. J. Agric. Food Chem. 53, 7198–7203 (2005)

S.K. Wendakoon, Y. Ueda, Y. Imahori, M. Ishimaru, Effect of short-term anaerobic conditions on the production of volatiles, activity of alcohol acetyltransferase and other quality traits of ripened bananas. J. Sci. Food Agric. 86, 1475–1480 (2006)

I. Eduardo, G. Chietera, D. Bassi, L. Rossini, A. Vecchietti, Identification of key odor volatile compounds in the essential oil of nine peach accessions. J. Sci. Food Agric. 90, 1146–1154 (2010)

C.V. Carcia, R.J. Stevenson, R.G. Atkinson, R.A. Winz, S.Y. Quik, Changes in the bound aroma profiles of “Hayward” and “Hort16A” kiwifruit (Actinidia spp.) during ripening and GC-olfactometry analysis. Food Chem. 137, 45–54 (2013)

Y. Tokitomo, M. Steinhaus, A. Buttner, P. Schieberle, Odor-active constituents in fresh pineapple (Ananas comosus [L.] Merr.) by quantitative and sensory evaluation. Biosci. Biotechnol. Biochem. 69, 1323–1330 (2005)

S.M. Malowicki, R. Martin, M.C. Qian, Volatile composition in raspberry cultivars grown in the Pacific Northwest determined by stir bar sorptive extraction-gas chromatography-mass spectrometry. J. Agric. Food Chem. 56, 4128–4133 (2008)

R.R. Jetti, E. Yang, A. Kurnianta, C. Finn, M.C. Qian, Quantification of selected aroma-active compounds in strawberries by headspace solid-phase microextraction gas chromatography and correlation with sensory descriptive analysis. J. Food Sci. 72, S487–S496 (2007)

M.E. Auldridge, D.R. McCarty, H.J. Klee, Plant carotenoid cleavage oxygenases and their apocarotenoid products. Curr. Opin. Plant Biol. 9, 315–321 (2006)

S. Kiani, S. Minaei, M. Ghasemi-Varnamkhasti, A portable electronic nose as an expert system for aroma-based classification of saffron. Chemometr. Intell. Lab. Syst. 156, 148–156 (2016)

W. Zhang et al., A study on soluble solids content assessment using electronic nose: persimmon fruit picked on different dates. Int. J. Food Prop. 19(1), 53–62 (2016)

H. Zhang et al., Application of electronic nose and statistical analysis to predict quality indices of peach. Food Bioprocess Technol. 5(1), 65–72 (2012)

S. Saevels et al., An electronic nose and a mass spectrometry-based electronic nose for assessing apple quality during shelf life. Postharvest Biol. Technol. 31(1), 9–19 (2004)

J. Brezmes et al., Correlation between electronic nose signals and fruit quality indicators on shelf-life measurements with pinklady apples. Sens. Actuators B 80(1), 41–50 (2001)

E. Llobet et al., Non-destructive banana ripeness determination using a neural network-based electronic nose. Meas. Sci. Technol. 10(6), 538 (1999)

A.H. Gomez, et al., Discrimination of storage shelf-life for mandarin by electronic nose technique. LWT-Food Sci. Technol. 40(4), 681–689 (2007)

M. Lebrun et al., Discrimination of mango fruit maturity by volatiles using the electronic nose and gas chromatography. Postharvest Biol. Technol. 48(1), 122–131 (2008)

H. Yu et al., Quality grade identification of green tea using E-nose by CA and ANN. LWT-Food Sci. Technol. 41(7), 1268–1273 (2008)

Z. Xiaobo, Z. Jiewen, “Comparative analyses of apple aroma by a tin-oxide gas sensor array device and GC/MS. Food Chem. 107(1), 120–128 (2008)

A.D. Wilson, M. Baietto, Applications and advances in electronic-nose technologies. Sensors 9(7), 5099–5148 (2009)

M. Falasconi et al., Electronic nose for microbiological quality control of food products. Int. J. Electrochem. (2012). doi:10.1155/2012/715763

S. Ampuero, J.O. Bosset, The electronic nose applied to dairy products: a review. Sens. Actuators B 94(1), 1–12 (2003)

H. Young et al., Characterization of Royal Gala apple aroma using electronic nose technology potential maturity indicator. J. Agric. Food Chem. 47(12), 5173–5177 (1999)

A. Sanaeifar et al., Development and application of a new low cost electronic nose for the ripeness monitoring of banana using computational techniques (PCA, LDA, SIMCA, and SVM). Czech J. Food Sci. 32, 538–548 (2014)

S. Nordiyana et al., Development of electronic nose for fruits ripeness determination. in 1st International Conference on Sensing Technology, Palmerston North, 2005

L. Pan et al., Early detection and classification of pathogenic fungal disease in post-harvest strawberry fruit by electronic nose and gas chromatography–mass spectrometry. Food Res. Int. 62, 162–168 (2014)

S. Benedetti et al., Electronic nose as a non-destructive tool to characterise peach cultivars and to monitor their ripening stage during shelf-life. Postharvest Biol. Technol. 47(2), 181–188 (2008)

S. Saevels et al., Electronic nose as a non-destructive tool to evaluate the optimal harvest date of apples. Postharvest Biol. Technol. 30(1), 3–14 (2003)

E.M. Pruteanu et al., Electronic nose for discrimination of Romanian apples. Lucr. Stiintifice 398–404 (2009)

C. Di Natale et al., Electronic nose based investigation of the sensorial properties of peaches and nectarines. Sens. Actuators B 77(1), 561–566 (2001)

A.H. Gómez et al., Electronic nose technique potential monitoring mandarin maturity. Sens. Actuators B 113(1), 347–353 (2006)

J. Brezmes et al., Evaluation of an electronic nose to assess fruit ripeness. IEEE Sens. J. 5(1), 97–108 (2005)

H. Zhang et al., Evaluation of peach quality indices using an electronic nose by MLR, QPST and BP network. Sens. Actuators B 134(1), 332–338 (2008)

J. Brezmes et al., Fruit ripeness monitoring using an electronic nose. Sens. Actuators B 69(3), 223–229 (2000)

H. Guohua et al., Fuji apple storage time predictive method using electronic nose. Food Anal. Methods 6(1), 82–88 (2013)

R. Infante, M. Farcuh, C. Meneses, Monitoring the sensorial quality and aroma through an electronic nose in peaches during cold storage. J. Sci. Food Agric. 88(12), 2073–2078 (2008)

L.P. Pathange et al., Non-destructive evaluation of apple maturity using an electronic nose system. J. Food Eng. 77(4), 1018–1023 (2006)

H. Zhang, J. Wang, S. Ye, Predictions of acidity, soluble solids and firmness of pear using electronic nose technique. J. Food Eng. 86(3), 370–378 (2008)

C. Di Natale et al., The evaluation of quality of post-harvest oranges and apples by means of an electronic nose. Sens. Actuators B 78(1), 26–31 (2001)

H. Gao, F. Zhu, J. Cai, A review of non-destructive detection for fruit quality. in International Conference on Computer and Computing Technologies in Agriculture. (Springer, Berlin, 2009)

B.M. Nicolai et al., Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: a review. Postharvest Biol. Technol. 46(2), 99–118 (2007)

H. Cen, Y. He, Theory and application of near infrared reflectance spectroscopy in determination of food quality. Trends Food Sci. Technol. 18(2), 72–83 (2007)

S.N. JHA, T. MATSUOKA, Non-destructive techniques for quality evaluation of intact fruits and vegetables. Food Sci. Technol. Res. 6(4), 248–251 (2000)

L.S. Magwaza et al., NIR spectroscopy applications for internal and external quality analysis of citrus fruit—a review. Food Bioprocess Technol. 5(2), 425–444 (2012)

K.-H. Choi, K.-J. Lee, G. Kim. Nondestructive quality evaluation technology for fruits and vegetables using near-infrared spectroscopy. in Proceedings of the International Seminar on Enhancing Export Competitiveness of Asian Fruits, Bangkok, Thailand, 2006

H. Huang et al., Near infrared spectroscopy for on/in-line monitoring of quality in foods and beverages: a review. J. Food Eng. 87(3), 303–313 (2008)

J. Lammertyn et al., Light penetration properties of NIR radiation in fruit with respect to non-destructive quality assessment. Postharvest Biol. Tecnol. 18(2), 121–132 (2000)

A. Peirs et al., Prediction of the optimal picking date of different apple cultivars by means of VIS/NIR-spectroscopy. Postharvest Biol. Technol. 21(2), 189–199 (2001)

A.J. Das et al., Ultra-portable, wireless smartphone spectrometer for rapid, non-destructive testing of fruit ripeness. Sci. Rep. 6, 32504 (2016)

P.N. Schaare, D.G. Fraser, Comparison of reflectance, interactance and transmission modes of visible-near infrared spectroscopy for measuring internal properties of kiwifruit (Actinidia chinensis). Postharvest Biol. Technol. 20(2), 175–184 (2000)

R. Lu, D.E. Guyer, R.M. Beaudry, Determination of firmness and sugar content of apples using near-infrared diffuse reflectance. J. Texture Studies 31(6), 615–630 (2000)

Z. Schmilovitch et al., Determination of mango physiological indices by near-infrared spectrometry. Postharvest Biol. Technol. 19(3), 245–252 (2000)

N. Sinelli et al., Evaluation of quality and nutraceutical content of blueberries (Vaccinium corymbosum L.) by near and mid-infrared spectroscopy. Postharvest Biol. Technol. 50(1), 31–36 (2008)

H.K. Noh, R. Lu, Hyperspectral laser-induced fluorescence imaging for assessing apple fruit quality. Postharvest Biol. Technol. 43(2), 193–201 (2007)

C. Camps, D. Christen, Non-destructive assessment of apricot fruit quality by portable visible-near infrared spectroscopy. LWT-Food Sci. Technol. 42, 1125–1131 (2009). 6)

A.H. Gomez, Y. He, A.G. Pereira, Non-destructive measurement of acidity, soluble solids and firmness of Satsuma mandarin using Vis/NIR-spectroscopy techniques. J. Food Eng. 77(2), 313–319 (2006)

S. Saranwong, J. Sornsrivichai, S. Kawano, Prediction of ripe-stage eating quality of mango fruit from its harvest quality measured nondestructively by near infrared spectroscopy. Postharvest Biol. Technol. 31(2), 137–145 (2004)

S. Bureau et al., Rapid and non-destructive analysis of apricot fruit quality using FT-near-infrared spectroscopy. Food. Chem. 113(4), 1323–1328 (2009)

D.G. Fraser et al., Light distribution inside mandarin fruit during internal quality assessment by NIR spectroscopy. Postharvest Biol. Technol. 27(2), 185–196 (2003)

J. Chandrapala et al., Ultrasonics in food processing. Ultrason. Sonochem. 19(5), 975–983 (2012)

M.T. Khairi et al., Contact and non-contact ultrasonic measurement in the food industry: a review. Meas. Sci. Technol. 27(1), 012001 (2015)

K.-l. Ha et al., A basic study on nondestructive evaluation of potatoes using ultrasound. Jpn. J. Appl. Phys. Part 1 30, 80–82 (1991)

A. Mizrach et al., Ultrasonic evaluation of some ripening parameters of autumn and winter-grown ‘Galia’melons. Sci. Hortic. 56(4), 291–297 (1994)

A. Mizrach, Nondestructive ultrasonic monitoring of tomato quality during shelf-life storage. Postharvest Biol. Technol. 46(3), 271–274 (2007)

R. Saggin, J.N. Coupland, Concentration measurement by acoustic reflectance. J Food Sci. (Chicago) 66(5), 681–685 (2001)

L. Gaete-Garretón et al., A novel noninvasive ultrasonic method to assess avocado ripening. J. Food Sci. 70(3), E187–E191 (2005)

Z.J. Dolatowski, J. Stadnik, D. Stasiak, Applications of ultrasound in food technology. Acta Scientiarum Polonorum Technologia Alimentaria 6(3), 88–99 (2007)

A. Mizrach, Ultrasonic technology for quality evaluation of fresh fruit and vegetables in pre-and postharvest processes. Postharvest Biol. Technol. 48(3), 315–330 (2008)

A. Mizrach, Assessing plum fruit quality attributes with an ultrasonic method. Food Res. Int. 37(6), 627–631 (2004)

A. Bechar et al., Determination of mealiness in apples using ultrasonic measurements. Biosyst. Eng. 91(3), 329–334 (2005)

A. Mizrach, U. Flitsanov, Predicting avocado shelf life by an ultrasonic nondestructive method. Acta Hortic 421, 111–119 (1995)

K.K. Bok et al., Evaluation of fruit firmness by ultrasonic measurement. Key Eng. Mater. 270, 1049–1054 (2004)

K.-B. Kim et al., Determination of apple firmness by nondestructive ultrasonic measurement. Postharvest Biol. Technol. 52(1), 44–48 (2009)

I. Aboudaoud et al., The maturity characterization of orange fruit by using high frequency ultrasonic echo pulse method. IOP Conf. Ser. 42(1), 012038 (2012)

M. Mizrach, U. Flitsanov, Nondestructive ultrasonic determination of avocado softening process. J. Food Eng. 40(3), 139–144 (1999)

R. Lewis et al., Characterising pressure and bruising in apple fruit. Wear 264(1), 37–46 (2008)

B.E. Verlinden, V. De Smedt, B.M. Nicolaı̈, Evaluation of ultrasonic wave propagation to measure chilling injury in tomatoes. Postharvest Biol. Technol. 32(1), 109–113 (2004)

A. Mizrach, Determination of avocado and mango fruit properties by ultrasonic technique. Ultrasonics 38(1), 717–722 (2000)

M. Zude et al., Non-destructive tests on the prediction of apple fruit flesh firmness and soluble solids content on tree and in shelf life. J. Food Eng. 77(2), 254–260 (2006)

F. Camarena, J.A. Martinez-Mora, Potential of ultrasound to evaluate turgidity and hydration of the orange peel. J. Food Eng. 75(4), 503–507 (2006)

M. Valente et al., Multivariate calibration of mango firmness using vis/NIR spectroscopy and acoustic impulse method. J. Food Eng. 94(1), 7–13 (2009)

S. Cubero et al., Advances in machine vision applications for automatic inspection and quality evaluation of fruits and vegetables. Food Bioprocess Technol. 4(4), 487–504 (2011)

T. Brosnan, D.-W. Sun, Improving quality inspection of food products by computer vision—a review. J. Food Eng. 61(1), 3–16 (2004)

N. Aleixos et al., Multispectral inspection of citrus in real-time using machine vision and digital signal processors. Comput. Electron. Agric. 33(2), 121–137 (2002)

C.-J. Du, D.-W. Sun, Learning techniques used in computer vision for food quality evaluation: a review. J. Food Eng. 72(1), 39–55 (2006)

T. Brosnan, D.-W. Sun, Inspection and grading of agricultural and food products by computer vision systems—a review. Comput. Electron. Agric. 36(2), 193–213 (2002)

J. Blasco et al., Citrus sorting by identification of the most common defects using multispectral computer vision. J. Food Eng. 83(3), 384–393 (2007)

V. Leemans, M.F. Destain, A real-time grading method of apples based on features extracted from defects. J. Food Eng. 61(1), 83–89 (2004)

G. ElMasry et al., Hyperspectral imaging for nondestructive determination of some quality attributes for strawberry. J. Food Eng. 81(1), 98–107 (2007)

A.B. Koc, Determination of watermelon volume using ellipsoid approximation and image processing. Postharvest Biol. Technol. 45(3), 366–371 (2007)

D. Ariana, D.E. Guyer, B. Shrestha, Integrating multispectral reflectance and fluorescence imaging for defect detection on apples. Comput. Electron. Agric. 50(2), 148–161 (2006)

B.S. Bennedsen, D.L. Peterson, Performance of a system for apple surface defect identification in near-infrared images. Biosyst. Eng. 90(4), 419–431 (2005)

J. Blasco, N. Aleixos, E. Moltó, Machine vision system for automatic quality grading of fruit. Biosyst. Eng. 85(4), 415–423 (2003)

J. Blasco, N. Aleixos, E. Molto, Computer vision detection of peel defects in citrus by means of a region oriented segmentation algorithm. J. Food Eng. 81(3), 535–543 (2007)

G. ElMasry, N. Wang, C. Vigneault, Detecting chilling injury in Red Delicious apple using hyperspectral imaging and neural networks. Postharvest Biol. Technol. 52(1), 1–8 (2009)

J. Blasco et al., Development of a machine for the automatic sorting of pomegranate (Punica granatum) arils based on computer vision. J. Food Eng. 90(1), 27–34 (2009)

S.P. Kang, A.R. East, F.J. Trujillo, Colour vision system evaluation of bicolour fruit: A case study with ‘B74’mango. \Postharvest Biol. Technol. 49(1), 77–85 (2008)

X. Liming, Z. Yanchao, Automated strawberry grading system based on image processing. Comput. Electron. Agric. 71, S32–S39 (2010)

L. Lleó et al., Multispectral images of peach related to firmness and maturity at harvest. J. Food Eng. 93(2), 229–235 (2009)

F. López-García et al., Automatic detection of skin defects in citrus fruits using a multivariate image analysis approach. Comput. Electron. Agric. 71(2), 189–197 (2010)

E. Borràs et al., Data fusion methodologies for food and beverage authentication and quality assessment—a review. Anal. Chim. Acta 891, 1–14 (2015)

S. Roussel et al., Authenticating white grape must variety with classification models based on aroma sensors, FT-IR and UV spectrometry. J. Food Eng. 60(4), 407–419 (2003)

M. Ruiz-Altisent, L. Lleó, F. Riquelme, Instrumental quality assessment of peaches: fusion of optical and mechanical parameters. J. Food Eng. 74(4), 490–499 (2006)

L. Rong, H. Ping, H. Wenlei, A novel method for wine analysis based on sensor fusion technique. Sens. Actuators B 66(1), 246–250 (2000)

C. Li, P. Heinemann, R. Sherry, Neural network and Bayesian network fusion models to fuse electronic nose and surface acoustic wave sensor data for apple defect detection. Sens. Actuators B 125(1), 301–310 (2007)

C. Di Natale et al., Outer product analysis of electronic nose and visible spectra: application to the measurement of peach fruit characteristics. Anal. Chim. Acta 459(1), 107–117 (2002)

Z. Xiaobo, Z. Jiewen, Apple quality assessment by fusion three sensors. in Sensors, 2005 IEEE. IEEE, 2005

J.I. Aranda-Sanchez, A. Baltazar, G. González-Aguilar, Implementation of a Bayesian classifier using repeated measurements for discrimination of tomato fruit ripening stages. Biosyst. Eng. 102(3), 274–284 (2009)

A. Baltazar, J.I. Aranda, G. González-Aguilar, Bayesian classification of ripening stages of tomato fruit using acoustic impact and colorimeter sensor data. Comput. Electron. Agric. 60(2), 113–121 (2008)

L.P. Brás et al., Multiblock PLS as an approach to compare and combine NIR and MIR spectra in calibrations of soybean flour. Chemometr. Intell. Lab. Syst. 75(1), 91–99 (2005)

S. Buratti et al., Characterization and classification of Italian Barbera wines by using an electronic nose and an amperometric electronic tongue. Anal. Chim. Acta 525(1), 133–139 (2004)

X. Hong, J. Wang, Detection of adulteration in cherry tomato juices based on electronic nose and tongue: Comparison of different data fusion approaches. J. Food Eng. 126, 89–97 (2014)

F. Mendoza, R. Lu, H. Cen, Comparison and fusion of four nondestructive sensors for predicting apple fruit firmness and soluble solids content. Postharvest Biol. Technol. 73, 89–98 (2012)

S. Roussel et al., Fusion of aroma, FT-IR and UV sensor data based on the Bayesian inference. Application to the discrimination of white grape varieties. Chemometr. Intell. Lab. Syst. 65(2), 209–219 (2003)

Felix, instruments, home page. https://felixinstruments.com/food-science instruments/portable-nir-analyzers/f-750-produce-quality-meter/. Accessed 10 May 2017

Sunforest, home page. http://sunforest.en.ec21.com/. Accessed 10 May 2017

Trturoni, home page, retrieved from http://www.trturoni.com/en/content/8-da-meter. Accessed 10 May 2017

Unitech, home page. http://www.postharvest.biz/en/company/unitecspa/_id:29711,seccion:productcatalog,producto:10531/. Accessed 10 May 2017

Omega, home page. http://in.omega.com/pptst/HFH80.html. Accessed 10 May 2017

Food, sniffer, home page. http://www.myfoodsniffer.com/. Accessed 10 May 2017

Sunshine, instruments, home page. http://www.digitalinstrumentsindia.com/digital-measuring-instruments.html#fruit-hardness-tester-20-kg-fr-5120-lutron-instruments. Accessed 10 May 2017

Vaiseshika electronic devices, home page. https://www.indiamart.com/vaiseshika. Accessed 10 May 2017

M. Valipour, M.A.G. Sefidkouhi, M. Raeini, Selecting the best model to estimate potential evapotranspiration with respect to climate change and magnitudes of extreme events. Agric. Water Manage. 180, 50–60 (2017). Accessed 10 May 2017

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srivastava, S., Sadistap, S. Non-destructive sensing methods for quality assessment of on-tree fruits: a review. Food Measure 12, 497–526 (2018). https://doi.org/10.1007/s11694-017-9663-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-017-9663-6