Abstract

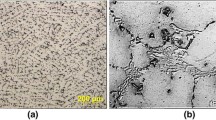

The main causes of creep failure in the pigtails and tubes made of high-temperature Incoloy 800HT and HP-modified alloy materials of two natural gas primary reformers operating at a petrochemical plant complex were studied. Optical emission spectroscopy, high-resolution optical microscopy, scanning electron microscopy, and energy-dispersive x-ray spectroscopy were performed to verify that creep was the prevailing failure mechanism in both cases. Creep was confirmed in both cases by the (massive) presence of intergranular voids (aligned in some cases) at the grain boundaries and cracks originating from the edge and longitudinal to the edge in some areas. Localized overheating due to burner flame impingement most likely accelerated the creep rate deformation for the HP-modified reformer tube material though the material surpassed its design life of 100,000 h. The findings substantiate that high priority should be placed on reformer burner management and ensuring the catalyst in the reformer tubes is packed optimally to avoid downstream flows issues in the outlet pigtails. These measures can serve to mitigate the effects of localized heating that can contribute to the failure of these components.

Similar content being viewed by others

References

Special Metals Corporation. The Story of the “Incoloy Alloys Series,” from 800, through 800H, 800HT (2004), http://www.specialmetals.com/documents/Incoloy%20alloys%20800H%20800HT.pdf. Accessed 16 May 2017

C. Maharaj, C.A.C. Imbert, J. Dear, Failure analysis and creep remaining life of hydrogen reformer outlet pigtail tubes. Eng. Fail. Anal. 15, 1076–1087 (2008)

ASTM International, in ASTM A297/A297 M-17 Standard Specification for Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, for General Application. Book of Standards Volume: 01.02 (ASTM International, West Conshohocken, 2017)

C.M. Schillmoller, in HP Modified Furnace Tubes for Steam Reformers and Steam Crackers. NiDITechnical Series, 1992, p. 1–11

American Society of Mechanical Engineers, in ASME SB-407 Specification for nickel-iron-chromium alloy seamless pipe and tube, ASME Boiler and Pressure Vessel Code II Part B Nonferrous Material Specifications.( American Society of Mechanical Engineers, New York, 2010)

S. Holdsworth, Creep-fatigue failure diagnosis. Materials 8, 7757–7769 (2015)

D. French. Creep and Creep Failures. National Board Classic Series (1991), http://www.nationalboard.org/Index.aspx?pageID=181. Accessed 23 May 2017

T.L.D. Silveira, I.L. May, Reformer furnaces: materials, damage mechanisms, and assessment. Arab. J. Sci. Eng. 21(2C), 99–119 (2006)

J. Huber, D. Jacobi, Centricast Materials for High- Temperature Service, in International Conference & Exhibition Nitrogen + Syngas (Dusseldorf, Germany, 2011)

M. Fulger et al., Analyses of oxide films grown on AISI 304L Stainless Steel and Incoloy 800HT exposed to supercritical water. J. Nucl. Mater. 415, 147–157 (2011)

Bohler Welding Group, Ni and HT steel alloys for Petrochemical Applications. (UTP Schweissmaterial Application Technology, 2012), p. 1–40

H.M. Tawancy et al., Failure analysis of catalytic steam reformer tubes. Anti Corros. Methods Mater 52(6), 337–344 (2005)

C. Maharaj, J.P. Dear, A. Morris, A review of methods to estimate creep damage in low-alloy steel power station steam pipes. Strain 45(4), 316–331 (2009)

M.A. Maleque, M.S. Salit, Materials Selection and Design (Springer, Singapore, 2013)

A. Anwer, Reformer Tubes Material Selection (Articles and Publications, 2017), http://www.thepetrostreet.com/article_0011.html. Accessed 15 May 2017

F. Gulshan et al., Failure analysis of superheater tubes supports of the primary reformer in a fertilizer factory. J. Fail. Anal. Prev. 5(3), 67–72 (2005)

S.A.J. Jahromi, M. Naghikhani, Failure analysis of HP40-Nb modified primary reformer tube of ammonia plant. Iran. J. Sci. Technol. Trans. B 28(2), 269–271 (2004)

K. Hasegawa., in Repair Welding and Metallurgy of HP-Modified Alloy after Long Term Operation. Metal 2001. (Czech Republic, 2001)

R. Voicu, et al., in Damage measurements after creep tests on samples of HP-40 alloys modified with a low level addition of Nb, ICF 12. (Canada, 2008), p. 1–10

M.H. Shariat, In advanced Creep Failure of H.P. Modified Reformer Tubes in an Ammonia Plant. The Journal of Corrosion Science and Engineering 6(H012), 1–20 (2003)

ASTM International, in ASTM E3-11 Standard Guide for Preparation of Metallographic Specimens. Book of Standards. (ASTM International, West Conshohocken, 2011)

Acknowledgments

The authors would like to thank Ms. Janell C. Ramlal for her support in carrying out this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maharaj, C., Marquez, A. & Khan, R. Failure Analysis of Incoloy 800HT and HP-Modified Alloy Materials in a Reformer. J Fail. Anal. and Preven. 19, 291–300 (2019). https://doi.org/10.1007/s11668-019-00621-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-019-00621-1