Abstract

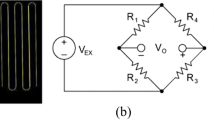

During development testing of prototype aero gas turbine engines in a test bed, various types of defects are expected to be detected related to the design drawbacks, material properties, manufacturing process and engine running conditions. The probability of occurrence of such cases is seen in an increasing trend when tests are performed on -initio development engine toward airworthiness qualification goals, wherein the use of nondestructive testing is warranted extensively. This paper discusses the methodology adopted to assess and decipher the condition of strain-gauged first-stage compressor stator vanes using eddy current testing. It is concluded that this method is very valuable for the investigation of components under practical scenarios arising out of development tests of aero gas turbine engines.

Similar content being viewed by others

References

W. Tian, M. Pan, D. Chen, Integrative in-situ detection of defects in aeroengine blades combining borescope and eddy current techniques, in 18th World Conference on Non Destructive Testing, Durban, South Afrcia, 16–20 Apr 2012

N.S. Cheruvu, K.S.Chan, Leverant, Blade Life Management: Coating Systems, EPRI, Palo Alto, CA. 1006608, pp 4-1 (2002)

M.R. Vijaya Lakshmi, A.K. Mondal, Shubhanjali, C.K. Jadhav, S, Sreedhar, Quantitative NDE Of aero engine turbine rotor blade-a case study, in Proceedings of National Seminar and Exhibition on Non-Destructive Evaluation, NDE2011, 8–10 Dec, 2011, Chennai, India

P. Russhard, The rise and fall of the rotor blade strain gauge. Vibration engineering and technology of machinery, in Proceedings of VETOMAC X 2014, 09-11 Sept 2014, University of Manchester, UK

J. Pitkanen, T. Hakkarainen, H. Jeskanen, P. Kuusinen, K. Lahdenperä, P. Särkiniemi, NDT methods for revealing anomalies and defects in gas turbine blades, in 15th World Conference on Non-Destructive Testing,15–21 Oct 2000, Rome, Italy

B. Sasi, B.P.C. Rao, T. Jayakumar, Dual-frequency eddy current non-destructive detection of fatigue cracks in compressor discs of aero engines. Def Sci J 54(4), 563 (2004)

P. Auerkari, J. Pitkänen, Maintenance of gas turbines—impact and implications for NDT, in 8th European Conference on Non-Destructive Testing, Barcelona, June 2002

M.R. Vijaya Lakshmi, A.K. Mondal, Shubhanjali, M.V. Subbaraju, V. Thangavelu, S. Sreedhar, Multiple NDE methods for crack characterization in spur gear, in 8th International Symposium on NDT in Aerospace, 3–5 Nov , Bangalore, 2016

Acknowledgments

The authors take this opportunity to express gratitude to Director, GTRE, for his continuous encouragement to carry out this work and also according permission to publish the findings. The authors also acknowledge Quality Assurance, Compressor, Vibration and Instrumentation Groups for their extensive technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vijaya Lakshmi, M.R., Mondal, A.K., Shubhanjali et al. Condition Assessment of Strain-Gauged Aero Engine Compressor Stator Vanes Using Eddy Current Testing. J Fail. Anal. and Preven. 18, 588–591 (2018). https://doi.org/10.1007/s11668-018-0435-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-018-0435-3