Abstract

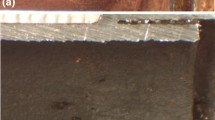

A metallurgical evaluation was performed to investigate two failures from carbonate-containing sour water service at a refinery. The failure mechanism for both fractured components (a pipe and a heat exchanger tube) was alkaline carbonate stress corrosion cracking. Alkaline carbonate stress corrosion cracking is a mechanism that has become more widely recognized in refinery service. This paper details the visual, SEM/EDS, metallographic, and microhardness evaluations used to determine the failure mechanism for each refinery component.

Similar content being viewed by others

References

Review and Survey of Alkaline Carbonate Stress Corrosion Cracking in Refinery Sour Waters. NACE International Publication 34108. p 2, 5–6, 13, and 20

Nalco Company, Stress Corrosion Cracking. The Nalco Guide to Boiler Failure Analysis (McGraw Hill, London, 2011), p 281

R.D. Kane, Corrosion in petroleum refining and petrochemical operations, in Corrosion: Environments and Industries, vol 13C, ASM Handbook (ASM International, 2006), p. 317

Standard Material Requirements: Materials Resistant to Sulfide Stress Cracking in Corrosive Petroleum Refining Environments. NACE Standard MR0103-2012, p 7–8

W.R. Warke, Stress-corrosion cracking, in Failure Analysis and Prevention, vol 11, ASM Handbook (ASM International, 2002), p. 839

Damage Mechanisms Affecting Fixed Equipment in the Refining Industry. API Recommended Practice 571, 2nd edn. (2011), p. 5–60 and 5–72

Acknowledgments

The authors would like to thank Stephen Davis, who was one of the principal investigators for the evaluation of the heat exchanger tube.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haase, R.J., Hanke, L.D. Alkaline Carbonate SCC Failures at a Refinery. J Fail. Anal. and Preven. 18, 153–161 (2018). https://doi.org/10.1007/s11668-018-0391-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-018-0391-y