Abstract

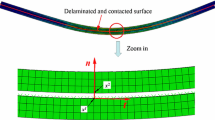

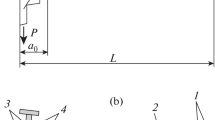

Progressive failure of ductile porous adhesive joint generally includes two competitive failure modes: the void growth of ductile adhesive layer and the interface debonding between the adhesive layer and bonding plates. The damage evolution behavior and ultimate strength of ductile adhesive joint are largely dominated by their evolving interactions. However, most of the existing research failed to predict the damage evolution of these two failure modes simultaneously. After the variational weak form of dynamic equilibrium for two adhesive solids with a finite-thickness adhesive layer and two discontinuous cohesive interfaces is given, this paper studies theoretically the competition between these two failure modes using explicit finite element analysis (FEA). The finite-deformation Gurson–Tvergaard–Needleman (GTN) model is used to predict the void growth of adhesive layer, and the bilinear cohesive model as a ABAQUS module is used to simulate the interface debonding. For single-lap joint under tensile loads, effects of the cohesive strengths, the initial void volume fraction, and the thickness of adhesive layer on their interactions are explored. Besides, the ultimate strengths by FEA are also compared with analytical solutions. Numerical results show that dominating failure mode changes from the interface debonding to the failure of adhesive layer at about the cohesive strength 40 MPa and the thickness of adhesive layer 0.5 mm for FM-73 ductile adhesive joint.

Similar content being viewed by others

References

F. Mortensen, O.T. Thomsen, Analysis of adhesive bonded joints: a unified approach. Compos. Sci. Technol. 62, 1011–1031 (2002)

C.D.M. Liljedahl, A.D. Crocombe, M.A. Wahab, I.A. Ashcroft, Damage modelling of adhesively bonded joints. Int. J. Fract. 141, 147–161 (2006)

G. Li, P. Lee-Sullivan, R.W. Thring, Nonlinear finite element analysis of stress and strain distributions across the adhesive thickness in composite single-lap joints. Compos. Struct. 46, 395–403 (1999)

R.D.S.G. Campilho, M.D. Banea, A.M.G. Pinto, L.F.M. da Silva, A.M.P. de Jesus, Strength prediction of single-and double-lap joints by standard and extended finite element modelling. Int. J. Adhes. Adhes. 31(5), 363–372 (2011)

P. Davies, L. Sohier, J.Y. Cognard, A. Bourmaud, D. Choqueuse, E. Rinnert, R. Créac’hcadec, Influence of adhesive bond line thickness on joint strength. Int. J. Adhes. Adhes. 29, 724–736 (2009)

G. Ji, Z. Ouyang, G. Li, S. Ibekwe, S.S. Pang, Effects of adhesive thickness on global and local Mode-I interfacial fracture of bonded joints. Int. J. Solids Struct. 47, 2445–2458 (2010)

L.F.M. da Silva, T.N.S.S. Rodrigues, M.A.V. Figueiredo, M.F.S.F. de Moura, J.A.G. Chousal, Effect of adhesive type and thickness on the lap shear strength. J. Adhes. 82, 1091–1115 (2006)

D.S. Dugdale, Yielding of steel sheets containing slit. J. Mech. Phys. Solids 8, 100–104 (1960)

G.I. Barenblatt, The mathematical theory of equilibrium cracks in brittle fracture. Adv. Appl. Mech. 7, 55–129 (1962)

B.R.K. Blackman, H. Hadavinia, A.J. Kinloch, J.G. Williams, The use of a cohesive zone model to study the fracture of fibre composites and adhesively-bonded joints. Int. J. Fract. 119, 25–46 (2003)

V. Tvergaard, Effect of fibre debonding in a whisker-reinforced metal. Mater. Sci. Eng., A 125, 203–213 (1990)

Q.D. Yang, M.D. Thouless, S.M. Ward, Elastic–plastic mode-II fracture of adhesive joints. Int. J. Solids Struct. 38, 3251–3262 (2001)

V. Tvergaard, J.W. Hutchinson, The influence of plasticity on mixed mode interface toughness. J. Mech. Phys. Solids 41, 1119–1135 (1993)

M.S. Kafkalidis, M.D. Thouless, The effects of geometry and material properties on the fracture of single lap-shear joints. Int. J. Solids Struct. 39, 4367–4383 (2002)

P.A. Gustafson, A.M. Waas, The influence of adhesive constitutive parameters in cohesive zone finite element models of adhesively bonded joints. Int. J. Solids Struct. 46, 2201–2215 (2009)

W. Xu, Y. Wei, Influence of adhesive thickness on local interface fracture and overall strength of metallic adhesive bonding structures. Int. J. Adhes. Adhes. 40, 158–167 (2013)

R.D.S.G. Campilho, M.D. Banea, J. Neto, L.F.M. da Silva, Modelling of single-lap joints using cohesive zone models: effect of the cohesive parameters on the output of the simulations. J. Adhes. 88, 513–533 (2012)

K.N. Anyfantis, Finite element predictions of composite-to-metal bonded joints with ductile adhesive materials. Compos. Struct. 94, 2632–2639 (2012)

P.F. Liu, Z.P. Gu, X.Q. Peng, A nonlinear cohesive/friction coupled model for shear induced delamination of adhesive composite joint. Int. J. Fract. 199, 135–156 (2016)

X.P. Xu, A. Needleman, Void nucleation by inclusion debonding in a crystal matrix. Model. Simul. Mater. Sci. Eng. 1, 111–132 (1993)

J.P. McGarry, É.Ó. Máirtín, G. Parry, G.E. Beltz, Potential-based and non-potential-based cohesive zone formulations under mixed-mode separation and over-closure. Part I: theoretical analysis. J. Mech. Phys. Solids 63, 336–362 (2014)

P.F. Liu, M.M. Islam, A nonlinear cohesive model for mixed-mode delamination of composite laminates. Compos. Struct. 106, 47–56 (2013)

C. Sarrado, F.A. Leone, A. Turon, Finite-thickness cohesive elements for modeling thick adhesives. Eng. Fract. Mech. 168, 105–113 (2016)

J. de Castro, T. Keller, Design of robust and ductile FRP structures incorporating ductile adhesive joints. Compos. Part B 41, 148–156 (2010)

R.D.S.G. Campilho, M.D. Banea, J.A.B.P. Neto, L.F.M. da Silva, Modelling adhesive joints with cohesive zone models effect of the cohesive law shape of the adhesive layer. Int. J. Adhes. Adhes. 44, 48–56 (2013)

A. Chadegani, R.C. Batra, Analysis of adhesive-bonded single-lap joint with an interfacial crack and a void. Inter. J. Adhes. Adhes. 31, 455–465 (2011)

A. Sengab, R.A. Talreja, Numerical study of failure of an adhesive joint influenced by a void in the adhesive. Compos. Struct. 156, 165–170 (2016)

P.H. Belnoue, S.R. Hallett, Cohesive/adhesive failure interaction in ductile adhesive joints Part I: a smeared-crack model for cohesive failure. Int. J. Adhes. Adhes. 68, 359–368 (2016)

N. Arnaud, R. Créac’hcadec, J.Y. Cognard, A tension/compression–torsion test suited to analyze the mechanical behaviour of adhesives under non-proportional loadings. Int. J. Adhes. Adhes. 53, 3–14 (2014)

A.L. Gurson, Continuum theory of ductile rupture by void nucleation and growth. I. Yield criteria and flow rules for porous ductile media. J. Eng. Mater. Technol. 99, 2–15 (1977)

V. Tvergaard, A. Needleman, Analysis of the cup-cone fracture in a round tensile bar. Acta Mater. 32, 157–169 (1984)

P.P. Camanho, C.G. Davila, M.F. de Moura, Numerical simulation of mixed-mode progressive delamination in the composite materials. J. Compos. Mater. 37, 1415–1438 (2003)

A. Turon, P.P. Camanho, J. Costaa, C.G. Dávila, A damage model for the simulation of delamination in advanced composites under variable-mode loading. Mech. Mater. 38, 1072–1089 (2006)

P.F. Liu, Z.P. Gu, Y.H. Yang, X.Q. Peng, A nonlocal finite element model for progressive failure analysis of composite laminates. Compos. Part B Eng. 86, 178–196 (2016)

P.F. Liu, Z.P. Gu, X.Q. Peng, J.Y. Zheng, Finite element analysis of the influence of cohesive law parameters on the multiple delamination behaviors of composites under compression. Compos. Struct. 131, 975–986 (2015)

T.J.R. Hughes, The Finite Element Method: Linear Static and Dynamic Finite Element Analysis (Dover Publications, New York, 2000)

Z.L. Zhang, A sensitivity analysis of material parameters for the Gurson constitutive model. Fatigue Fract. Eng. Mater. Struct. 19, 561–570 (1996)

A. Oral, G. Anlas, J. Lambros, Determination of Gurson–Tvergaard–Needleman model parameters for failure of a polymeric material. Int. J. Damage Mech. 21, 3–25 (2012)

H. Cui, Simulation of ductile adhesive failure with experimentally determined cohesive law. Compos. Part B 92, 193–201 (2016)

G. Dean, L. Crocker, B. Read, L. Wright, Prediction of deformation and failure of rubber-toughened adhesive joints. Int. J. Adhes. Adhes. 24, 295–306 (2004)

R.D. Adams, J. Comyn, W.C. Wake, Structural Adhesive Joints in Engineering (Springer Science & Business Media, Berlin, 1997)

L. Liao, C. Huang, Numerical analysis of effects of adhesive type and geometry on mixed-mode failure of adhesive joint. Int. J. Adhes. Adhes. 68, 389–396 (2016)

K. Turan, Y. Pekbey, Progressive failure analysis of reinforced-adhesively single-lap joint. J. Adhes. 91, 962–977 (2015)

J.H. Park, J.H. Choi, J.H. Kweon, Evaluating the strengths of thick aluminum-to-aluminum joints with different adhesive lengths and thicknesses. Compos. Struct. 92, 2226–2235 (2010)

K. Naito, M. Onta, Y. Kogo, The effect of adhesive thickness on tensile and shear strength of polyimide adhesive. Int. J. Adhes. Adhes. 36, 77–85 (2012)

M.D. Banea, L.F.M. da Silva, Mechanical characterization of flexible adhesives. J. Adhes. 85, 261–285 (2009)

M. Corrado, M. Paggi, Nonlinear fracture dynamics of laminates with finite thickness adhesives. Mech. Mater. 80, 183–192 (2015)

Acknowledgments

Prof. Pengfei Liu would sincerely like to thank the support of the Project of Key Laboratory for Design and Manufacturing of Offshore Wind Power Blade of Jiangsu Province, the National Key Fundamental Research and Development Project of China (No. 2015CB057603), the Open Project of State Key Laboratory of Mechanics and Control of Mechanical Structures of Nanjing University of Aeronautics and Astronautics of China (No. MCMS-0216G01), and the Open Project of State Key Laboratory for Strength and Vibration of Mechanical Structures of Xi’an Jiaotong University of China (No. SV2015-KF-09).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, P.F., Hu, Z.H., Wang, S.B. et al. Finite Element Analysis of the Void Growth and Interface Failure of Ductile Adhesive Joints. J Fail. Anal. and Preven. 18, 291–303 (2018). https://doi.org/10.1007/s11668-018-0389-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-018-0389-5