Abstract

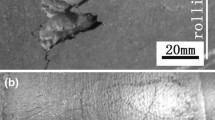

The present paper focuses on asperity contact during cold rolling at a microscopic level. As analyses of such a contact are not practical with experimental facilities, a three-dimensional finite element method (FEM) is adopted to simulate the indentation and furrow behaviors of a single asperity on work roll surface in mixed lubrication. The effects of the tensile stress, the hydrodynamic pressure and the plastic deformation of steel strip are considered comprehensively. Most calculations are done for parabolic asperities, but for comparison purposes, some results are presented for sinusoidal and elliptical asperities. The indentation behaviors including uplift height of edges and plastic deformations of strip steel are calculated and analyzed. The friction during furrow behaviors is also considered. It reveals that the reduction and lubrication condition has a significant effect on the uplift height of strip steel edges around the asperity. Furthermore, long-term repeated effects of mixed lubrication contact are liable to spark asperity wear and decrease the roughness of rolls and even cause the failure of rolls in strip rolling mills.

Similar content being viewed by others

References

K.L. Johnson, Contact Mechanics (Cambridge University Press, Cambridge, 1985)

W.R. Chang, I. Etsion, D.B. Bogy, Static friction coefficient model for metallic rough surfaces. ASME J. Tribol. 110(1), 57–63 (1988)

Y. Kimura, T.H.C. Childs, Surface asperity deformation under bulk plastic straining conditions. Int. J. Mech. Sci. 41(3), 283–307 (1999)

V.S. Deshpande, D.S. Balint, A. Needleman, E. Van der Giessen, Size effects in single asperity frictional contacts. Model Simul. Mater. Sci. Eng. 15(1), S97–S108 (2007)

M. Eriten, Multiscale Physics-Based Modeling of Friction (University of Illinois Urbana-Champaign, Urbana, 2012)

I. Nogueira, F. Robbe-Valloire, R. Gras, Experimental validations of elastic to plastic asperity-based models using normal indentations of rough surfaces. Wear 269(11), 709–718 (2010)

T. Goda, K. Váradi, K. Friedrich, H. Giertzsch, Finite element analysis of a polymer composite subjected to a sliding steel asperity part I normal fibre orientation. J. Mater. Sci. 37(8), 1575–1583 (2002)

R.L. Jackson, L. Kogut, A comparison of flattening and indentation approaches for contact mechanics modeling of single asperity contacts. J. Tribol. 128(1), 209–212 (2006)

T.D.S. Botelho, R. Progri, G. Inglebert, F. Robbe-Valloire, Analytical and experimental elastoplastic spherical indentations of a layered half-space. Mech. Mater. 40(10), 771–779 (2008)

Z. Song, K. Komvopoulos, Elastic–plastic spherical indentation: deformation regimes, evolution of plasticity, and hardening effect. Mech. Mater. 61(8), 91–100 (2013)

M. Liu, H. Proudhon, Finite element analysis of frictionless contact between a sinusoidal asperity and a rigid plane: elastic and initially plastic deformations. Mech. Mater. 77, 125–141 (2014)

Q. Dong, J. Cao, Contact deformation analysis of elastic-plastic asperity on rough roll surface in a strip steel mill. J. Fail. Anal. Prev. 15(2), 320–326 (2013)

S.W. Lo, T.C. Yang, H.S. Lin, The lubricity of oil-in-water emulsion in cold strip rolling process under mixed lubrication. J. Tribol. 66, 125–133 (2013)

W.R.D. Wilson, S. Kalpakjian, Low-speed mixed lubrication of metal-forming processes. Ann. CIRP 44(1), 205–208 (1995)

T.D. Ta, A.K. Tieu, H. Zhu, Q. Zhu, P.B. Kosasih, J. Zhang, G. Deng, Tribological behavior of aqueous copolymer lubricant in mixed lubrication regime. ACS Appl. Mater. Interfaces 8(8), 5641–5652 (2016)

D. Xu, J. Zhang, H. Li, J. Lu, Q. Fan, H. Dong, Research on surface topography wear of textured work roll in cold rolling. Ind. Lubr. Tribol. 67(3), 269–275 (2015)

A.S. Galakhar, J.D. Gates, W.J.T. Daniel, P.A. Meehan, Adhesive tool wear in the cold roll forming process. Wear 271(11), 2728–2745 (2011)

S. Huart, M. Dubar, R. Deltombe, A. Dubois, L. Dubaret, Asperity deformation, lubricant trapping and iron fines formation mechanism in cold rolling processes. Wear 257(5), 471–480 (2004)

R. Li, Q. Zhang, X. Zhang, M. Yu, B. Wang, Control method for steel strip roughness in two-stand temper mill rolling. Chin. J. Mech. Eng. 28(3), 573–579 (2015)

B. Lorentz, A. Albers, A numerical model for mixed lubrication taking into account surface topography, tangential adhesion effects and plastic deformations. Tribol. Int. 59, 259–266 (2013)

Acknowledgments

The authors would like to express their appreciation for the continuous supports from National Natural Science Foundation of China (No. 51404023), the National Key Technology R&D Program of the 12th Five-year Plan of China (No. 2015BAF30B01), National Natural Science Foundation of China (No. 51604024), Project Funded by China Postdoctoral Science Foundation (No. 2016M590042) and Fundamental Research Funds for the Central Universities (No. FRF-TP-15-001A1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, C., Li, H. & Zhang, J. Research on Contact Behavior of Single Asperity on Work Roll Surface in Mixed Lubrication. J Fail. Anal. and Preven. 18, 75–82 (2018). https://doi.org/10.1007/s11668-017-0382-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-017-0382-4