Abstract

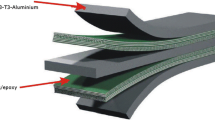

The present paper characterizes the structure of 3D model of an aircraft wing leading edge of a passenger aircraft considering GLARE laminates as one of the candidate materials through finite element analysis. The investigation is carried out on different types of GLARE configurations and the results of finite element analysis are well compared analytically with benchmark tests to demonstrate the performance of the modeling technique adopted. The GLARE laminate materials are found suitable for their application in the wing leading edge with some reservation on GLARE 3/2 and GLARE 4/3 for Al alloy 2024-T3 thickness, between 0.2 and 0.4 mm. The finite element approach is able to predict the mechanical behavior of structural elements fast enough so that the results can be incorporated into normal design iteration processes.

Similar content being viewed by others

References

J. Thorpe, Fatalities and destroyed civil aircraft due to bird strikes, 1912–2002, in International Bird Strike Committee, 26th Meeting (Warsaw, 2003)

R.K. Mishra, S.I. Ahmed, K. Srinivasan, Investigation of a bird strike incident of a military gas turbine engine. J. Fail. Anal. Prev. 13(6), 666–672 (2013). doi:10.1007/s11668-013-9744-8

S. Heimbs, Bird strike simulations on composite aircraft structures, in SIMULIA Customer Conference (Barcelona, 2011)

C. Niu, Airframe Structural Design: Practical Design Information and Data on Aircraft Structures (Conmilit Press, Hong Kong, 1988)

T.H.G. Megson, Aircraft Structures for Engineering Students (Elsevier, Amsterdam, 2012)

M. Mukhopadhyay, Mechanics of Composite Materials and Structures (Universities press, Hyderabad, 2005)

L.B. Vogelesang, A. Vlot, Development of fibre metal laminates for advanced aerospace structures. J. Mater. Process. Technol. 103(1), 1–5 (2000)

R.J. Gettens, G.L. Stout, Painting Materials: A Short Encyclopaedia (Courier Corporation, 1966)

G. Wu, J.-M. Yang, The mechanical behavior of GLARE laminates for aircraft structures. JOM 57(1), 72–79 (2005)

J.B. Young, J.G.N. Landry, V.N. Cavoulacos, Crack growth and residual strength characteristics of two grades of glass-reinforced aluminium ‘Glare’. Compos. Struct. 27(4), 457–469 (1994)

B.P. Shetty, S. Reddy, R.K. Mishra, Numerical analysis of bird impact on glass-reinforced leading edge of an aircraft wing. J. Fail. Anal. Prev. (2017). doi:10.1007/s11668-017-0306-3

L.J. Clancy, Aerodynamics (Halsted Press, Sydney, 1975)

R.T. Jones, Wing Theory (Princeton University Press, Princeton, 2014)

M.H. Dickinson, K.G. Gotz, Unsteady aerodynamic performance of model wings at low Reynolds numbers. J. Exp. Biol. 174(1), 45–64 (1993)

Shubham. Agarwal, Priyank. Kumar, Numerical investigation of flow field and effect of varying vortex generator location on wing performance. Am. J. Fluid Dyn. 6(1), 11–19 (2016)

W. Shyy et al., Aerodynamics of Low Reynolds Number Flyers, vol. 22 (Cambridge University Press, Cambridge, 2007)

M.L. Averill, Simulation Modeling and Analysis, 4th edn. (Tata McGraw-Hill Publishing Company Ltd, New Delhi, 2008)

R.M. Pinkerton, The variation with Reynolds number of pressure distribution over an airfoil section, in NACA Report No. 613 (National Advisory Committee for Aeronautics, 1937)

E.N. Jacobs, K.E. Ward, R.M. Pinkerton, The characteristics of 78 related airfoil sections from tests in the variable-density wind tunnel, NACA-TR-460, PB-177874 (1933)

P. Iaccarino, A. Langella, G. Caprino, A simplified model to predict the tensile and shear stress-strain behavior of fiberglass/aluminum laminates. Compos. Sci. Technol. 67, 1784–1793 (2007)

H.W. Nam, W. Hwang, K.S. Han, Stacking sequence design of fiber-metal laminate for maximum strength. J. Compos. Mater. 35(18), 1654–1683 (2001)

F. Rastellini et al., Composite materials non-linear modelling for long fibre-reinforced laminates: continuum basis, computational aspects and validations. Comput. Struct. 86(9), 879–896 (2008)

C.-H. Lin, M.-H.R. Jen, Analysis of a laminated anisotropic plate by Chebyshev collocation method. Compos. Part B 36, 155–169 (2005)

G.R. Liu, X. Han, K.Y. Lam, An inverse procedure for determination of material constants. Comput. Methods Appl. Mech. Eng. 191, 3543–3554 (2002)

A.K. Onkar, C.S. Upadhyay, D. Yadav, Probabilistic failure of laminated composite plate using the stochastic finite element method. Compos. Struct. 77, 79–91 (2007)

A.M. Gadade, A. Lal, B.N. Singh, Finite element implementation of Puck’s failure criterion for failure analysis of laminated plate subjected to biaxial loadings. Aerosp. Sci. Technol. 55, 227–241 (2016)

H. Debski, J. Jonak, Failure analysis of thin-walled composite channel section columns. Compos. Struct. 132, 567–574 (2015)

M. Hagenbeck, Characterization of Fiber Metal Laminates Under Thermomechanical Loadings. GLARE Data Hand Book, Doctoral Thesis (2005)

G. Wu, J.-M. Yang, Analytical modeling and numerical simulation of the non-linear deformation of hybrid fiber metal laminates. Model. Simul. Mater. Sci. Eng. 13, 413–425 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shetty, B.P., Reddy, S. & Mishra, R.K. Finite Element Analysis of an Aircraft Wing Leading Edge Made of GLARE Material for Structural Integrity. J Fail. Anal. and Preven. 17, 948–954 (2017). https://doi.org/10.1007/s11668-017-0331-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-017-0331-2