Abstract

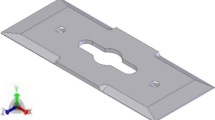

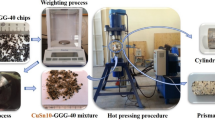

This paper addresses wear failure analysis of tungsten carbide (WC) hardfacing on a carbon steel blade known as the continuous digester blade (CD blade). The CD blade was placed in a digester tank to mix ilmenite ore with sulphuric acid as part of a production process. Tungsten carbide hardfacing was applied on the CD blade to improve its wear resistance while the CD blade was exposed to an abrasive and acidic environment. Failure analysis was carried out on the hardfaced CD blade in order to improve its wear resistance and lifetime. A thickness and hardness comparison study was conducted on worn and unworn specimens from the CD blades. The carbide distribution along with elemental composition analysis of the hardfaced CD blade specimens was examined using scanning electron microscopy and energy-dispersive spectroscopy. The investigation revealed that an inconsistent hardfacing thickness was welded around the CD blade. Minimum coating thickness was found at the edges of the blade surfaces causing failure to the blades as the bare carbon steel blades were exposed to the mixed environment. The wear resistance of the CD blade can be improved by distributing the carbide uniformly on the hardfaced coating. Applying extra coating coverage at the critical edge will prevent the exposure of bare carbon steel blade, thus increasing the CD blade lifetime.

Similar content being viewed by others

References

K.H. Lau, D. Mei, C.F. Yeung, H.C. Man, Wear characteristics and mechanisms of a thin edge cutting blade. J. Mater. Process. Technol. 102(1), 203–207 (2000)

B.K. Prasad, S.V. Prasad, Abrasion-induced microstructural changes during low stress abrasion of a plain carbon (0.5% C) steel. Wear 151(1), 1–12 (1991)

T. Foley, A. Levy, The effect of heat treatment on the erosion behaviour of steel. Wear Mater. 1983, 346–353 (1983)

C.K. Kwok, G. Thomas, Microstructural Influence on Abrasive Wear Resistance of High-Strength, High-Toughness Medium-Carbon Steels (No. LBL-14911; CONF-830402-2) (Lawrence Berkeley Lab., CA, 1982)

A.S. Kang, G.S. Cheema, S. Singla, Wear behaviour of hardfacings on rotary tiller blades. Procedia Eng. 97, 1442–1451 (2014)

V. Shibe, V. Chawla, An overview of research work in hardfacing. Mechanica Confab, 2(3), 105–110 (2013)

V. Lazić, A. Sedmak, I. Samardžić, S. Aleksandrović, D. Milosavljević, D. Arsić, M. Đorđević, Determination of bond strength between the hardfaced (HF) layer and the base material (BM) of forging dies. Metalurgija 55(1), 91–94 (2016)

J. Liu, S. Yang, W. Xia, X. Jiang, C. Gui, Microstructure and wear resistance performance of Cu–Ni–Mn alloy based hardfacing coatings reinforced by WC particles. J. Alloys Compd. 654, 63–70 (2016)

N.A. Ahmad, Z. Kamdi, Z. Mohamad, A.S. Omar, N.A. Latif, A.M. Tobi, Characterization of WC-10Ni HVOF coating for carbon steel blade, in IOP Conference Series: Materials Science and Engineering (Vol. 165, No. 1, IOP Publishing, 2017), p. 012022

A.M. Tobi, Z. Kamdi, M.I. Ismail, M. Nagentrau, L.N.H. Roslan, Z. Mohamad, N.A. Latif, Abrasive wear failure analysis of tungsten carbide hard facing on carbon steel blade, in IOP Conference Series: Materials Science and Engineering (Vol. 165, No. 1, IOP Publishing, 2017), p. 012020.

R. Kejžar, J. Grum, Hardfacing of wear-resistant deposits by MAG welding with a flux-cored wire having graphite in its filling. Mater. Manuf. Process. 20(6), 961–976 (2005)

B. Venkatesh, K. Sriker, V.S.V. Prabhakar, wear characteristics of hardfacing alloys: state-of-the-art. Procedia Mater. Sci. 10, 527–532 (2015)

M. Antonov, R. Veinthal, D.L. Yung, D. Katušin, I. Hussainova, Mapping of impact-abrasive wear performance of WC–Co cemented carbides. Wear 332, 971–978 (2015)

E. Badisch, M. Kirchgaßner, Influence of welding parameters on microstructure and wear behaviour of a typical NiCrBSi hardfacing alloy reinforced with tungsten carbide. Surf. Coat. Technol. 202(24), 6016–6022 (2008)

S. Chatterjee, T.K. Pal, Wear behaviour of hardfacing deposits on cast iron. Wear 255(1), 417–425 (2003)

E. Badisch, C. Mitterer, Abrasive wear of high speed steels: influence of abrasive particles and primary carbides on wear resistance. Tribol. Int. 36(10), 765–770 (2003)

E. Pagounis, V.K. Lindroos, Processing and properties of particulate reinforced steel matrix composites. Mater. Sci. Eng. A 246(1), 221–234 (1998)

Y. Bayhan, Reduction of wear via hardfacing of chisel ploughshare. Tribol. Int. 39(6), 570–574 (2006)

R. Dasgupta, B.K. Prasad, A.K. Jha, O.P. Modi, S. Das, A.H. Yegneswaran, Low stress abrasive wear behavior of a hardfaced steel. J. Mater. Eng. Perform. 7(2), 221–226 (1998)

K. Van Acker, D. Vanhoyweghen, R. Persoons, J. Vangrunderbeek, Influence of tungsten carbide particle size and distribution on the wear resistance of laser clad WC/Ni coatings. Wear 258(1), 194–202 (2005)

R. Chotěborský, P. Hrabě, M. Müller, R. Válek, J. Savková, M. Jirka, Effect of carbide size in hardfacing on abrasive wear. Res. Agric. Eng. 55(4), 149–158 (2009)

Acknowledgments

The authors acknowledge the financial support by the Ministry of Education Malaysia and Universiti Tun Hussein Onn Malaysia. This research is supported by the Knowledge Transfer Programme (KTP), Vot. No. 1483.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nagentrau, M., Tobi, A.L.M., Kamdi, Z. et al. A Study on Wear Failure Analysis of Tungsten Carbide Hardfacing on Carbon Steel Blade in a Digester Tank. J Fail. Anal. and Preven. 17, 861–870 (2017). https://doi.org/10.1007/s11668-017-0320-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-017-0320-5