Abstract

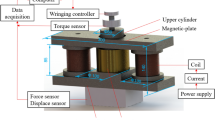

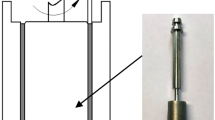

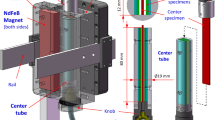

In order to research the rheological property of MRF at high shear rate, a magnetorheological fluid (MRF) rheological property testing device based on shear mode, is developed. The accurate analytical expressions of MRF rheological parameters in terms of structural dimensions of testing device and shear rate in the parallel plate gap are derived, and the flow state of MRF is considered, which provides the theoretical foundation for testing the rheological property of MRF at high shear rate. The relationship between magnetic indication in the parallel plate gap and excitation electrical current is experimentally obtained. Some elements influencing testing are analyzed and eliminated. The device is used to test the rheological parameters of MRF, and the results show that the yield stress of MRF increases significantly as the magnetic flux density continues to increase, and shear rate has no obvious effect on it. The shear rates in designed device may exceed 3 × 104 s−1, which meets the special demands in MRF testing.

Similar content being viewed by others

References

A.C. Becnel, S. Sherman, W. Hu, N.M. Wereley, Nondimensional scaling of magnetorheological rotary shear mode devices using the Mason number. J. Magn. Magn. Mater. 380, 90–97 (2015)

G. Dirk, V. Erbis, M. Schamoni, J. Maas, Design and characteristics of MRF-based actuators for torque transmission under influence of high shear rates up to 34,000 s−1. Active Passive Smart Struct. Integr. Syst. 9057, 79–84 (2014)

G. Dirk, S. Markus, M. Jürgen, Magnetic fluid control for viscous loss reduction of high-speed MRF brakes and clutches with well-defined fail-safe behavior. Smart Mater. Struct. 22(9), 94010–94021 (2013)

W. Hu, N.M. Wereley, Behavior of MR fluids at high shear rate. Int. J. Modern Phys. 25(7), 979–985 (2011)

S.G. Sherman, A.C. Becnel, N.M. Wereley, Relating Mason number to Bingham number in magnetorheological fluids. J. Magn. Magn. Mater. 380, 98–104 (2015)

H. Bai, A. Stephenson, J. Jimenez, D. Jewell, P. Gillis, Modeling flow and residence time distribution in an industrial-scale reactor with a plunging jet inlet and optional agitation. Chem. Eng. Res. Des. 86(12), 1462–1476 (2008)

X.J. Wang, F. Gordaninejad, Flow Analysis of field-controllable, electro and magnetorheological fluids using Herschel–Bulkley model. J. Intell. Mater. Syst. Struct. 10(8), 601–608 (1999)

F.D. Goncalves, M. Ahmadian, J.D. Carlson, Investigating the magnetorheological effect at high flow velocities. Smart Mater. Strut. 15, 75–85 (2006)

H.R. Mao, Y.G. Meng, Y. Tian, Experimental study on the compressive effect of ER fluids. J. Tsinghua Univ. 42(11), 1441–1443 (2002)

S.M. Chen, C.G. Wei, Experimental study on the performance of ER fluids. Chin. J. Mech. Eng. 38(9), 87–90 (2002)

Z.W. Wang, K. Shahrivar, J.D. Vicente, Creep and recovery of magnetorheological fluids: experiments and simulations. J. Rheol. 58(6), 1725–1750 (2014)

H.M. Laun, C. Gabriel, Measurement modes of the response time of a magneto-rheological fluid (MRF) for changing magnetic flux density. Rheol. Acta 46(5), 665–676 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kang, L., Luo, Y. & Liu, Y. Testing Device for Rheological Properties of Magnetorheological Fluid at High Shear Rate. J Fail. Anal. and Preven. 17, 563–570 (2017). https://doi.org/10.1007/s11668-017-0277-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-017-0277-4