Abstract

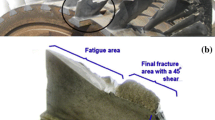

Blades are key components of gas turbine compressors which are frequently subjected to centrifugal and vibratory loads. These cyclic loadings result in degradation of physical and mechanical properties of the blades. Moreover, the blades operate at high temperature and in aggressive environments which makes monitoring their properties hard, and as a consequence their useful life service is limited. In order to prevent early and sudden failure of compressor blades, it seems rational to find out the reason for limited service life of the blades. Experimental and metallurgical investigations on a service-fractured compressor blade combined with blade simulation and stress analysis resulted in calculation of cycles for fatigue crack initiation and propagation and understanding of the sudden failure of the blade made of custom 450 alloy in this case study during service.

Similar content being viewed by others

References

M. Zhang, Y. Liu, W. Wang, P. Wang, J. Li, The fatigue of impellers and blades. Eng. Fail. Anal. 62, 208–231 (2016)

A.R. Rao, B.K. Dutta, Vibration analysis for detecting failure of compressor blade. Eng. Fail. Anal. 25, 211–218 (2012)

N.J. Lourenço, M.L.A. Graça, L.A.L. Franco, O.M.M. Silva, Fatigue failure of a compressor blade. Eng. Fail. Anal. 15, 1150–1154 (2008)

A. Kermanpur, A.H. Sepehri, S. Ziaei-Rad, N. Nourbakhshnia, M. Mosaddeghfar, Failure analysis of Ti6Al4V gas turbine compressor blades. Eng. Fail. Anal. 15, 1052–1064 (2008)

E. Silveria, G. Atxaga, A.M. Irisarri, Failure analysis of a set of compressor blades. Eng. Fail. Anal. 15, 666–674 (2008)

M.R. Jahangiri, A.A. Fallah, A. Ghiasipour, Cement kiln dust induced corrosion fatigue damage of gas turbine compressor blades—a failure analysis. Mater. Des. 62, 288–295 (2014)

E. Poursaeidi, A. Babaei, F. Behrouzshad, M.R. Mohammadi-Arhani, Failure analysis of an axial compressor first row rotating blades. Eng. Fail. Anal. 28, 25–33 (2013)

V. Ramamurti, D.A. Subramani, Free vibration analysis of a turbocharger centrifuge compressor impeller. Mech. Mach. Theory 30, 619–628 (1995)

W. Luejan, Experimental crack propagation and failure analysis of the first stage compressor blade subjected to vibration. Eng. Fail. Anal. 2, 1–8 (2009)

C.G. Su, W.Q. Wang, X.D. Shang, Research on the measurement of mechanical properties of common impeller materials through continuous ball indentation test. Fluid Mach. 43, 7–12 (2015)

S. Li, Y. Kang, S. Kuang, Effects of microstructure on fatigue crack growth behavior in cold-rolled dual phase steels. Mater. Sci. Eng., A 612, 153–161 (2014)

ASTM, A705/A705M-95 Standard Specification for Age-Hardening Stainless Steel Forgings (American Society for Testing and Materials, West Conshohocken, PA, 2006)

S.I. Rokhlin, J.-Y. Kim, H. Nagy, B. Zoofan, Effect of fatigue corrosion on fatigue crack initiation and fatigue life. Eng. Fract. Mech. 62, 425–444 (1999)

P. Ernst, R.C. Newman, Pit growth studies in stainless steel foils. II. Effect of temperature, chloride concentration and sulphate addition. Corros. Sci. 44, 943–954 (2002)

M.F. Mc Guire, Stainless Steels for Design Engineers (ASM International, Materials Park, 2008)

P. Ernst, R.C. Newman, Pit growth studies in stainless steel foils. I. Introduction and pit growth kinetics. Corros. Sci. 44, 927–941 (2002)

A. Mokaberi, R. Derakhshandeh-Haghighi, Y. Abbaszadeh, Fatigue fracture analysis of gas turbine compressor blades. Eng. Fail. Anal. 58, 1–7 (2015)

W. Becker, Closed-form modeling of the unloaded mode I Dugdale crack. Eng. Fract. Mech. 57, 355–364 (1997)

V.T. Troshchenko, A.V. Prokopenko, Fatigue strength of gas turbine compressor blades. Eng. Fail. Anal. 7, 209–220 (2000)

R.C. Bates, W.G. Clark, Fractography and fracture mechanics. Trans. Q. ASM 62, 380–389 (1969)

R.W. Hertzberg, Deformation and Fracture Mechanics of Engineering Materials, 3rd edn. (Wiley, New York, 1989)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Derakhshandeh-Haghighi, R. Metallurgical Analysis and Simulation of a Service-Fractured Compressor Blade Made of ASTM S45000 Alloy. J Fail. Anal. and Preven. 17, 522–528 (2017). https://doi.org/10.1007/s11668-017-0269-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-017-0269-4