Abstract

The failure of BOF hood tube is a common industrial problem that has received little attention in literature. The major mode of failure as observed by most of the industries is thermal fatigue failure. Earlier people have studied the thermal stress profile in hood system considering constant water temperature. However, in reality there are fluctuations in water temperature due to cyclic thermal load caused by BOF gas. Present study reveals that the water temperature fluctuation is having significant impact in causing thermal fatigue failure. The change in water velocity and tube thickness has negligible effect in thermal fatigue failure compared to that observed for water temperature fluctuation. However, tube material of construction is also having significant impact on its failure.

Similar content being viewed by others

References

T. Ondrey, Improvements made to USS Edgar Thomson BOF hood system, in AISE Conference on Prolonging BOF Hood Life (Nashville, Tennessee, 1998)

M.L. Wei, Survey of BOF hoods in North America. Iron Steel Eng. 75(4), 25–30 (1998)

M.L. Wei, International Survey of BOF hoods, in Conference Proceedings of BOF Hoods for the 21st Century (Nashville, Tennessee, 2000)

R.E. Hargraave, D.J. Kotwica, Common failure mechanisms in BOF hoods. Iron Steel Eng. 73(11), 22–28 (1996)

I.V. Samarasekera, Mathematical modeling of thermal stresses in basic oxygen furnace hood tubes. Met. Trans. B 16(2), 247–261 (1985)

S.K. Saha, D.J. Radakovic, T.A. Walden, Life extension of BOF lower hood at U. S. Steel Canada’s Lake Erie Works via engineering and design changes, in AISTech Proceedings (Pittsburgh, 2013), pp. 929–938

J.F. Mcgurn, Composite tubes in black liquor recovery boilers: an update. Pulp Pap. Canada 94, 12 (1993)

H.C. Hottel, Radiant Heat Transmission, 3rd edn, Chap. 4, Heat Transmission (McGraw-Hall Book Company, New York, 1964)

G.A. Stemetzki, M.M. Kuta, C. Shepard, BOF hood life cycle cost improvement program. Iron Steel Technol. 1(1), 54–67 (2004)

L.C. Boyd Jr., V.K. Sikka, Aluminum bronze alloys to improve the system life of basic oxygen and electric arc furnace hoods, roofs and side vents. Final Report, U. S. Department of Energy (DOE) Information Bridge, 2006, p. 22

J.T.P. Castro, R.D. Vieira, A.C.N. Vidal, A.C.O. Miranda, J.L.F. Freire, M.A. Meggiolaro, A case study on corrosion-thermal fatigue damage, R. Marquês de S. Vicente, Rio de Janeiro, Brazil, unpublished literature, 2005

J.D. Zupanovich, Oxidation and Degradation Products of Common Oxygen Scavengers. Report (Chem Tech Inc., USA, 2002)

P.K. Das, A.K. Gupta, N. Nirmalkar, R.P. Chhabra, Effect of confinement on forced convection from a heated sphere in Bingham plastic fluids. Korea Austrailia Rheol. J. 27(2), 75–94 (2015)

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Process Description of Cooling Water Circuit

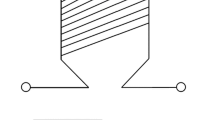

From the overhead tank (OHT), water comes into the makeup water tank which is used for supplying makeup water to the cooling water circuit. From the makeup, water goes into expansion tank via pump-I. Expansion tank is used in a closed water system to absorb excess water pressure caused by thermal expansion. From expansion tank via pump-2, water goes into the supply header where water flow is divided into several branches as shown in Fig. 1. One part goes into the cooling stack, another goes into the movable hood, and the third one goes into the movable skirt. From the cooling stack and movable hood, water goes into the receiving header, whereas from movable skirt one part goes to the skirt hydraulic and other part goes into flux chute before going into the receiving header. From the receiving header, water passed through fin fan heat exchangers for its temperature to get down through fin fan cooling before finally circulated into the expansion tank. It is important to note here that dissolve oxygen is a major concern as it reacts with the hood tube material to cause corrosion. To control the dissolve oxygen in the water, chemical dosing is done into the water circuit just after the expansion tank. Basically carbohydrazide-based chemical dosing is done into the water which acts as an oxygen scavenger. It reacts with dissolved oxygen directly as shown below [12].

At room temperature, the first reaction (Eq 13) is much faster than the rest two reactions. However, at elevated temperature release of hydrazine and carbon dioxide becomes significant due to the increasing reaction rate of the second reaction (Eq 14).

It is to note here that carbohydrazide also helps in protecting the hood tubes by forming passive iron oxides required for iron passivation. The reaction is shown as follows:

Rights and permissions

About this article

Cite this article

Das, P.K., Sarkar, S. & Ajmani, S.K. Transient Thermal Stress Analysis of BOF Hood Failure. J Fail. Anal. and Preven. 17, 496–504 (2017). https://doi.org/10.1007/s11668-017-0267-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-017-0267-6