Abstract

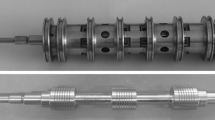

Hydraulic control actuation systems in launch vehicles use flexible hoses for transmission of forces to actuators at different locations. The hose ends are connected to the interface adapters by AISI 304 stainless steel sleeves. These sleeves are assembled to nipple end fittings of the high-pressure hose by a swaging operation to obtain leak-proof hose assemblies. The swaging operation is carried out at room temperature by a hydraulically operated swaging machine. Performance of the system as a whole requires strict adherence to the quality standards maintaining the critical interface dimensions within specified tolerances and ensuring the compression given to the swaged joint through the sleeve. If the joining forces are less, this can result in loose joints and gross leakage, whereas excessive compression can cause damage to the parts of the system namely the sleeve, stainless steel braid, PTFE or the adapter. The swaged joint is a single-point failure mode, indicating that a failure in the joint can lead to mission failure. It has to withstand harsh environments such as high pressure, low and high temperature extremes, fatigue loading due to pressure cycling as well as vibration. Therefore, as part of design verification, a detailed qualification plan has been prepared and the hoses were tested as per the plan. As per the test plan, these hoses undergo acceptance tests which include pneumatic and hydraulic pressure testing. During acceptance testing of hoses, one of the hose sleeves was found to be cracked. The cracking was observed after carrying out the pneumatic test when the assembly was being prepared for hydraulic pressure set-up. This paper describes the detailed metallurgical investigation carried out to understand the cause of failure and actions taken to avoid similar failures.

Similar content being viewed by others

References

R. Singh, B. Ravikumar, A. Kumar, P.K. Dey, I. Chattoraj, The effects of cold working on sensitization and intergranular corrosion behavior of AISI 304 stainless steel. Metall. Mater. Trans. A 34A, 2441–2447 (2003)

A. Das, S. Sivaprasad, M. Ghosh, P.C. Chakraborti, S. Tarafder, Morphologies and characteristics of deformation induced martensite during tensile deformation of 304 LN stainless steel. Mater. Sci. Eng. A 486, 283–286 (2008)

V. Kain, K. Chandra, K.N. Adhe, P.K. De, Effect of cold work on low temperature sensitization behavior of austenitic stainless steels. J. Nucl. Mater. 334, 115–132 (2004)

R. Kiessling, Non-metallic inclusions in steel, 2nd edn. (The Metals Society, London, 1977)

E.T. Turkdogan, Theoretical aspects of sulphide formation in steel, in Sulphide inclusions in steel (ASM, 1975), pp. 1–22

I. Kozasu, J. Tanaka, Effects of sulphide inclusions on notch toughness and ductility of structural steels, in Sulphide inclusions in steel (ASM, 1975), pp. 286–308

A.J. DeArdo, Jr., E.G. Hamburg, Influence of elongated inclusions on the mechanical properties of high strength steel plate, in Sulphide inclusions in steel (ASM, 1975), pp. 309–337

J.R. Davis, Metals Handbook (Materials Park, ASM International, 1998). Desk edition

Aerospace Material Specification, AMS-5647H, SAE Aerospace (2007)

Aerospace Material Specification, AMS-5639H, SAE Aerospace (2007)

Acknowledgments

Authors wish to thank Director, VSSC for the continuous support in carrying out the study and for permitting to publish the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Murugesan, V., Sreejith, P.S., Manwatkar, S.K. et al. Failure Analysis of AISI 304 Stainless Steel Sleeve Used in High-Pressure Hose Assembly of Actuation System of a Satellite Launch Vehicle. J Fail. Anal. and Preven. 17, 178–188 (2017). https://doi.org/10.1007/s11668-016-0232-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-016-0232-9