Abstract

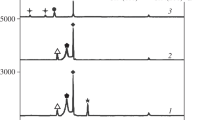

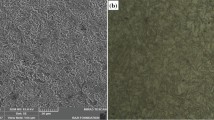

The 20MnMoNb steels were gas-oxynitrided for 2 h at 610 °C in a controlled atmosphere by the self-making process control system and gas oxynitriding technology. The microstructure, hardness, wear and corrosion resistance of the 20MnMoNb steels by gas oxynitriding were studied by OM, XRD, hardness test, wear test and neutral salt spray test. The results show that the thickness of diffuse layer is about 0.25 mm and that of the compound layer formed on the surface is about 50 μm. The compound layer is made of bulky columnar crystals, which have different morphology in the different form positions. The compound layer surface of gas-oxynitrided specimens consists of ε-Fe3N, magnetite—Fe3O4 and inner surface consists of ε-Fe3N and Fe4N. The different oxygen and nitrogen concentrations lead to different morphologies in the different positions of bulky column crystals. The compound layer has a good hardness distribution and high wear and corrosion resistance.

Similar content being viewed by others

References

S. Audisio, M. Caillet, A. Galerie, H. Mazille, Traitements de surface et protection contre la corrosion (Ecole d’été CNRS, Aussois, 1987), pp. 361–371. (Les Editions de Physique)

A. Constant, G. Henry, J.C. Charbonnier, Principes de base des traitements thermiques, thermomécaniques et thermochimiques des aciers (PYC, Baldwinsville, 1992), pp. 328–334

D. Ghiglione, C. Leroux, C. Tournier, Pratique des traitements thermochimiques: nitruration, nitrocarburation et dérivés. Tech. Ing. M 1227, 1–43 (1988)

A. Çelik, S. Karadeniz, Surf. Coat. Technol. 80, 283–286 (1996)

M. Tacikowski, I. Ulbin-Pokorska, T. Wierzchon, Microstructure of the composite oxynitrided chromium layers produced on steel by a duplex method. Surf. Coat. Technol. 201(6), 2776–2781 (2006)

J.R. Sobiecki, T. Wierzchoń, Glow discharge assisted oxynitriding of the binary Ti6Al2Cr2Mo titanium alloy. Vacuum 79(3–4), 203–208 (2005)

J. Kazior, C. Janczur, T. Pieczonka, J. Ploszczak, Thermochemical treatment of Fe–Cr–Mo alloys. Surf. Coat. Technol. 151–152(1), 333–337 (2002)

J.R. Sobiecki, T. Wierzchoń, J. Rudnicki, The influence of glow discharge nitriding, oxynitriding and carbonitriding on surface modification of Ti-1Al-1Mn titanium alloy. Vacuum 64(1), 41–46 (2001)

T. Wierzchoń, I. Ulbin-Pokorska, K. Sikorski, Corrosion resistance of chromium nitride and oxynitride layers produced under glow discharge conditions. Surf. Coat. Technol. 130(2–3), 274–279 (2000)

L. Jian, Study on oxi-nitridizing process. Hot Work. Technol. 37(8), 78–79 (2008)

Zhou Pan-bing, Zhou Lang, Chen Zhong-bo, Comparison of microstructures and properties between oxy-nitrided and nitrided with post-oxidized h igh speed steel. Metal Heat Treat. 32(5), 27–30 (2007)

Long Fa-jin, Zhou Shang-qi, Liu Lin-fei, Ren Qin, Research progress on nitriding and oxidation combined processes. Hot Work. Technol. 5, 50–52 (2004)

Wu Zhang Huai-qing, Sun Jian-jun Xin-tao, Analysis and application of rapid gas nitriding process with preoxidizing method. Metal Heat Treat. 26(11), 31–33 (2001)

Acknowledgment

This work was supported by Fundamental Research Funds for the Central Universities of China (A0920502051619-65) and Natural Science Foundation of China (NSFC: 51601156, U1537201).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, J., Jiang, R., Zhang, C. et al. Study on Microstructure and Properties of 20MnMoNb Steel by Gas Oxynitriding. J Fail. Anal. and Preven. 17, 154–158 (2017). https://doi.org/10.1007/s11668-016-0225-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-016-0225-8