Abstract

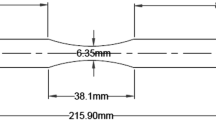

One of the important applications of high tensile steel grades is in wheel rims by the automotive industry. High tensile steel facilitates vehicle weight reduction under the ‘Go Green’ initiative. Along with weight reduction, in recent times, the surface quality requirement of steels for wheel rim applications has also gained a significant focus, and in many cases, it is becoming the cause of rejection at the customers’ processing line. It is known that owing to chemistry requirements such high strength steel grades generally show peritectic behavior during solidification and are prone to surface defects. Tata Steel India produces several wheel rim grades of varying strength levels. In one such high manganese and micro-alloyed peritectic steel grade, the rejection by the customer on account of surface defects was a major concern. The defects consisted of typical longitudinal cracks of varying dimensions along with the unique defects in transverse direction named tear marks on the surface of 100-mm-thick plates rolled from 215-mm-thick slab. In subsequent stages, these plates were processed into rim profiles through hot working by the wheel customer. The paper highlights how systematic study led to arrive at root causes and helped redesign steel chemistry to ensure zero rejection for surface quality without affecting mechanical property requirements.

Similar content being viewed by others

References

A. Grill, J.K. Brimacombe, Influence of carbon content on the rate of heat extraction in the mould of a continuous casting machine. Ironmak. Steelmak. 140, 76–79 (1976)

B. Mintz, Hot ductility of steels and its relationship to the problem of transverse cracking during continuous casting. Int. Mater. Rev. 36, 187–217 (1991)

Y. Maehara, K. Yasumoto, H. Tomono, T. Nagamichi, Y. Ohmori, Surface cracking mechanism of continuously cast low carbon low alloy steel slabs. Mater. Sci. Technol. 6(9), 793–806 (1990)

M. Wolf, W. Kurz, The effect of carbon content on solidification of steel in the continuous casting mold. Metall. Trans. B 12, 85–93 (1981)

V. Karlinski, W. Fogazzi, B.V. de Souza, C.R.F. Ferreira, C.A. dos Santos, J.A. Spim, A ferrite potential influence on heat transfer conditions in industrial mold during the continuous casting of steels. Engenharia Termica (Thermal Engineering) 8(1), 18–23 (2009)

Piyush Choudhary, Internal Report, Tata Steel Ltd, 2011

B. Patrick, V. Ludlow, Development of casting practices to minimize transverse cracking in micro alloyed steel. Rev. Metall. 91, 1081–1089 (1994)

B. Mintz, J.M. Arrowsmith, Hot ductility behaviour of C–Mn–Nb–Al steels and its relationship to crack propagation during the straightening of continuously cast strands. Met. Technol. 6, 24–32 (1979)

B. Mintz, R. Abushosha, Ironmak. Steelmak. 20, 445–452 (1993)

B. Mintz, Influence of nitrogen on hot ductility of steels and its relationship to problem of transverse cracking. Ironmak. Steelmak. 27(5), 343–347 (2000)

C. Ouchi, K. Matsumoto, Hot ductility in Nb bearing high strength low alloy steels. Trans. ISIJ 22(3), 181–189 (1982)

D.N. Crowther, M.J.W. Green, P.S. Mitchell, The influence of composition on the hot cracking susceptibility during casting of micro alloyed steels processed to simulate hin slab conditions. Mater. Sci. Forum 284–286, 469–479 (1998)

N.A. McPherson, R.E. Mercer, Continuous casting of slabs at BSC Ravenscraig works. Ironmak. Steelmak. 7(4), 67–179 (1980)

T.H. Coleman, J.R. Wilcox, Transverse cracking in continuously cast HSLA slabs—influence of compositions. Mater. Sci. Technol. 1, 80–83 (1985)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roy, T.K. Elimination of Surface Defects in High Tensile Steel for Wheel Rim Application. J Fail. Anal. and Preven. 17, 93–99 (2017). https://doi.org/10.1007/s11668-016-0213-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-016-0213-z