Abstract

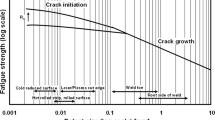

The effect of laser cut-edges has been studied as a method for producing an optimum fatigue life performance of advanced high-strength steel. During this study, DP600 high-strength steel laser cut-edges have been fatigue tested under S-N and E-N fatigue loading regimes. The cut-edge surface characteristic properties and internal metallurgical alterations have been observed to directly influence fatigue life of the steel. This paper has investigated the crack initiation and growth properties of the initial crack to mode two. It is shown that alterations in the surface properties can be harnessed so that beneficial properties can be produced to retard crack initiation. It was determined that the laser power and cutting speed can be used independently to produce the appropriate balance between microstructure and optimum surface properties. Optimal fatigue lives were attained by minimizing the laser cut-edge surface damage, maintaining the formation of wide area striations and by forming a uniform layer of martensitic material close to the cut-edge. These results suggest that laser cutting can be used to enhance the fatigue life to failure of fracture-sensitive steel grades.

Similar content being viewed by others

Abbreviations

- A:

-

Elongation to failure

- AHSS:

-

Advanced high-strength steel

- E-N:

-

Strain life

- HAZ:

-

Heat-affected zone

- HCF:

-

High cycle fatigue

- H V :

-

Vickers hardness

- kPa:

-

Kilopascal

- R a :

-

Arithmetic mean of departures from the mean line

- R q :

-

RMS of the R a

- R p :

-

Maximum height of profile above the mean line

- R v :

-

Maximum depth of profile below the mean line

- R t :

-

Total R p − R v

- S-N:

-

Stress life

- Wt:

-

Weight

References

S. Mullick, A.K. Agrawal, A.K. Nath, Effect of laser incidence angle on cut quality of 4 mm thick stainless steel sheet using fiber laser. Opt. Laser Technol. 81(1), 168–179 (2016)

C. Wandera, A. Salminen, V. Kujanpaa, Inert gas cutting of thick-section stainless steel and medium-section aluminium using a high power fiber laser. J. Laser Appl. 21(3), 154–161 (2009)

R. Poprawe, W. Schulz, R. Schmitt, Hydrodynamics of material removal by melt expulsion: perspectives of laser cutting and drilling. Phys. Proc. 5(1), 1–18 (2010)

C. Wandera, V. Kujanpaa, Characterization of the melt removal rate in laser cutting of thick-section stainless steel. J. Laser Appl. 22(2), 62–70 (2010)

L.D. Scintilla, L. Tricarico, A. Mahrle, A. Wetzig, E. Beyer, Experimental investigation on the cut front geometry in the inert gas laser fusion cutting with disk and CO2 lasers. 30th International Congress on Applications of Lasers and Electro-Optics, ICALEO 2011, pp. 40–49 (2011)

D.J. Thomas, The influence of the laser and plasma traverse cutting speed process parameter on the cut-edge characteristics and durability of Yellow Goods vehicle applications. J. Manuf. Process. 13(2), 120–132 (2011)

S. Cicero, T. García, J.A. Álvarez, A. Martín-Meizoso, J. Aldazabal, A. Bannister, A. Klimpel, Definition and validation of Eurocode 3 FAT classes for structural steels containing oxy-fuel, plasma and laser cut holes. Int. J. Fatigue 87, 50–58 (2016)

J. Powell, D. Petring, R.V. Kumar, S.O. Al-Mashikhi, A.F.H. Kaplan, K.T. Voisey, Laser-oxygen cutting of mild steel: the thermodynamics of the oxidation reaction. J. Phys. D: Appl. Phys. 42(1), Article No. 015504.

B.S. Yilbas, A.F.M. Arif, Laser cutting of steel and thermal stress development. Opt. Laser Technol. 43(4), 830–837 (2011)

A. Lamikiz, L.N.L.D. Lacalle, J.A. Sánchez, D.D. Pozo, J.M. Etayo, J.M. López, CO2 laser cutting of advanced high strength steels (AHSS). Appl. Surf. Sci. 242(3–4), 362–368 (2005)

B.T. Rao, R. Kaul, P. Tiwari, A.K. Nath, Inert gas cutting of titanium sheet with pulsed mode CO2 laser. Opt. Lasers Eng. 43(12), 1330–1348 (2005)

J. Powell, S.O. Al-Mashikhi, A.F.H. Kaplan, K.T. Voisey, Fibre laser cutting of thin section mild steel: an explanation of the ‘striation free’ effect. Opt. Lasers Eng. 49(8), 1069–1075 (2011)

A. Lara, I. Picas, D. Casellas, Effect of the cutting process on the fatigue behaviour of press hardened and high strength dual phase steels. J. Mater. Process. Technol. 213(11), 1908–1919 (2013)

E. Nagels, J.R. Duflou, J. Van Humbeeck, The influence of sulphur content on the quality of laser cutting of steel. J. Mater. Process. Technol. 194(1–3), 159–162 (2007)

B.S. Yilbas, C. Karatas, I. Uslan, O. Keles, Y. Usta, Z. Yilbas, M. Ahsan, Wedge cutting of mild steel by CO2 laser and cut-quality assessment in relation to normal cutting. Opt. Lasers Eng. 46(10), 777–784 (2008)

L.D. Scintilla, L. Tricarico, Estimating cutting front temperature difference in disk and CO2 laser beam fusion cutting. Opt. Laser Technol. 44(5), 1468–1479 (2012)

H.A. Eltawahni, M. Hagino, K.Y. Benyounis, T. Inoue, A.G. Olabi, Effect of CO2 laser cutting process parameters on edge quality and operating cost of AISI316L. Opt. Laser Technol. 44(4), 1068–1082 (2012)

L. Li, M. Sobih, P.L. Crouse, Striation-free laser cutting of mild steel sheets. CIRP Ann.: Manuf. Technol. 56(1), 193–196 (2007)

K. Kheloufi, E.H. Amara, Numerical investigation of the effect of some parameters on temperature field and kerf width in laser cutting process. Phys. Proc. 39, 872–880 (2012)

A. Lamikiz, L.N. López de Lacalle, J.A. Sánchez, D. del Pozo, J.M. Etayo, J.M. López, CO2 laser cutting of advanced high strength steels (AHSS). Appl. Surf. Sci. 242(3–4), 362–368 (2005)

D.J. Thomas, M.T. Whittaker, G.W. Bright, Y. Gao, The influence of mechanical and CO2 laser cut-edge characteristics on the fatigue life performance of high strength automotive steels. J. Mater. Process. Technol. 211, 263–274 (2011)

D.J. Thomas, Finite element analysis of laser cut edge beam section for high stress intensity structural performance. J. Fail. Anal. Prev. 16, 562–575 (2016)

Acknowledgments

The present research was funded by a grant from the Engineering and Physical Sciences Research Council (EPSRC). The author wishes to thank the support of Tata Steel during the pursuit of this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thomas, D.J. Life Assessment and Crack Growth Properties of Laser Cut Dual-Phase Steel. J Fail. Anal. and Preven. 16, 811–820 (2016). https://doi.org/10.1007/s11668-016-0156-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-016-0156-4