Abstract

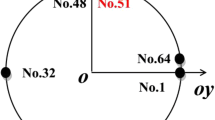

The bolts assembled on a tuning-wheel of a marine diesel engine were found fractured and loose in service of only 70 days. The damage and fractography features of the bolts were investigated to identify the failure sequence and the failure causes or modes. The crack origins were from the diameter surface of the bolts, and reverse bending and rotating bending fatigue fractures were the dominant failure modes. Various manufacturing defects, such as tight radii of transition fillet between the shanks and the threaded sections of bolts, poor surface roughness, and machined threads rather than cold-rolled threads, were found on the fractured bolts, which created a high stress concentration. A few bolts were loose in the first place during service, the overall stress state of the bolts changed to lead to a non-uniform distribution of load on the bolts. Some bolts had to sustain a great load, which was sufficient to cause fatigue crack initiation at the defective regions of bolts in such a short time period. Unsuitable installation procedures allowed for the possibility of low preload on the bolts leading to bolt loosening when subjected to vibrational loads during service. Additionally, bolt loosening could occur due to severe loading conditions. The bolts on the wheel failed in succession due to poor bolt manufacture and installation.

Similar content being viewed by others

References

China National Standardization Committee, Mechanical Properties of Fasteners—Bolts, Screws and Studs (GB13098.1-2010, China Standard, 2010) (in Chinese)

A.M. Heyes, Automotive component failures. Eng. Fail. Anal. 5, 129–141 (1998)

J. Daniel, Benac: technical brief: avoiding bolt failures. J. Fail. Anal. Prev. 7, 79–80 (2007)

M. Zamanzadeh, E. Larkin, R. Mirshams, Fatigue failure analysis case studies. J. Fail. Anal. Prev. (2015). doi:10.1007/s11668-015-0044-3

L.R. Curtis, Metallurgical failure analysis of fasteners in an impeller assembly. J. Fail. Anal. Prev. 6, 17–22 (2006)

S. Ifergane, N. Eliaz, N. Stern, E. Kogan, G. Shemesh, H. Sheinkopf, D. Eliezer, The effect of manufacturing processes on the fatigue lifetime of aeronautical bolts. Eng. Fail. Anal. 8, 227–235 (2001)

P. Palai, P. Sinha, T. Venugogalan, Analysis of slide gate mounting bolt fatigue in steel ladle due to fatigue. J Fail. Anal. Prev. 14, 662–667 (2014)

R. Lacalle, S. Cicero, O. Ferreno, J.A. Alvarez, Failure analysis of a bolt in scaffolding system. Eng. Fail. Anal. 15, 237–246 (2008)

D. Liu, X. Shang, Failure investigation of the wind turbine blade root bolt. J. Fail. Anal. Prev. 13, 333–339 (2013)

Acknowledgments

The project is supported by “the Fundamental Research Funds for the Central Universities (No. 3132014323).”

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Zw., Xu, Xl. Fracture Failure of Bolts Assembled in Tuning-Wheel of a Marine Diesel Engine. J Fail. Anal. and Preven. 16, 489–498 (2016). https://doi.org/10.1007/s11668-016-0109-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-016-0109-y