Abstract

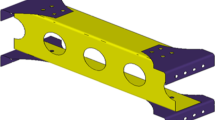

The combat aircraft utilizes high-speed flexible coupling (HSFC) to transmit the power from the aircraft engine gear box to accessory gearbox and to accommodate misalignment arises in the drive line. The HSFC input drive end has three shear bolts with predetermined shear torque set value. The mission-critical shear bolt failure to act above maximum set value will damage the down-line components by excess torque transmission. The premature action of shear bolts below minimum set value will deprive the power to single-engine aircraft transmission which may even lead to loss of aircraft. To realize consistency performance of shear bolts, sensitivity analysis is carried out considering influencing parameters like shear section size, hardness and preload variation. Based on the analysis, grouping of bolts was enabled for consistent performance in shear torques. The experimental validations are carried out to correlate between theoretical prediction and model behavior.

Similar content being viewed by others

References

M. Calistrat, Metal Diaphragm Coupling Performance, in Proceedings of the Fifth Turbomachinery Symposium, 1976, pp. 117–124

S. Nagesh, A.M. Junaid Basha, G. Thakur Dinesh Singh, Influence of applied misalignment on the balanced high speed flexible coupling of fighter aircraft. Appl. Mech. Mater. 592–594, 1084–1088 (2014)

S. Nagesh, A.M. Junaid Basha, G. Thakur Dinesh Singh, Dynamic performance analysis of high speed flexible coupling of gas turbine engine transmission system. J. Mech. Sci. Technol. 29(1), 173–179 (2015)

R.P. Czachor, Unique challenges for bolted joint design in high-bypass turbo-fan engines. J. Eng. Gas Turbines Power 127(2), 240–248 (2005)

J. Yoo, S.-J. Hong, J.S. Choi, Y.J. Kang, Design guide of bolt locations for bolted-joint plates considering dynamic characteristics. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 223(2), 363–375 (2009)

S. Melenciuc, V. Venghiac, Factors influencing the preload level of high strength bolts for structural steel connections. Rep. Gheorghe Asachi Tech. Univ. Iasi, Fac. Civ. Eng. Build. Serv., No. Lxi, 125–138 (2011)

W. Eccles, I. Sherrington, R.D. Arnell, Frictional changes during repeated tightening of zinc plated threaded fasteners. Tribol. Int. 43(4), 700–707 (2010)

T. Fukuoka, T. Takaki, Elastic plastic finite element analysis of bolted joint during tightening process. J. Mech. Des. 125(4), 823–830 (2003)

B.S.C. Ranjan, H.N. Vikranth, A. Ghosal, A novel prevailing torque threaded fastener and its analysis. J. Mech. Des. 135(10), 1010071–1010079 (2013)

D. Doyle, A. Zagrai, B. Arritt, H. Cakan, Damage detection in bolted space structures. J. Intell. Mater. Syst. Struct. 21(3), 251–264 (2009)

N. Pai, D. Hess, Three-dimensional finite element analysis of threaded fastener loosening due to dynamic shear load. Eng. Fail. Anal. 9, 383–402 (2002)

R.A. Ibrahim, C.L. Pettit, Uncertainties and dynamic problems of bolted joints and other fasteners. J. Sound Vib. 279(3–5), 857–936 (2005)

Specification for 1½ per cent nickel-chromium-molybdenum steel (90/110 kgf/mm2 (57/70 tonf/in2): limiting ruling section 150 mm (6 in) BS 3S 95:1967, British Standards Institution

ASM International, ASM Handbook Volume 4: Heat Treating. (ASM International, 1991)

J.H. Bickford, Introduction to the Design and Behavior of Bolted Joints: Non-Gasketed Joints, 4th edn. (CRC Press, Boca Raton, 2007), p. 568

R. Budynas, K. Nisbett, Shigley’s Mechanical Engineering Design (McGraw-Hill Education, New York, 2010), p. 1120

J. Gere, B. Goodno, Mechanics of Materials, SI edn. (Cengage Learning, Boston, 2012), p. 1056

G.E. Dieter, Mechanical Metallurgy (McGraw-Hill, London, 1988), p. 751

G.L. Kulak, J.W. Fisher, J.H.A. Struik, Guide to Design Criteria for Bolted and Riveted Joints (Wiley, New York, 1987), p. 333

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nagesh, S., Junaid Basha, A.M. & Thakur, D.G. Sensitivity Analysis of Mission Critical Shear Bolts of Combat Aircraft High-Speed Flexible Coupling. J Fail. Anal. and Preven. 15, 672–678 (2015). https://doi.org/10.1007/s11668-015-9990-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-015-9990-z