Abstract

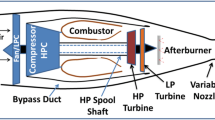

A multistage high-pressure compressor drum has been designed for a low bypass military turbofan engine. The complex mission profile of the engine with high throttle excursion demands reliable operation of the compressor throughout the flight envelope maintaining structural integrity. Therefore, qualification of the compressor drum for a fighter class engine is a challenge from the airworthiness point of view. This paper presents the methodology adopted and various stages of qualification, standards followed, and results based on which clearance has been accorded for fitment in engine and engine on aircraft. The compressors thus fitted in engine have exhibited satisfactory performance and are at different stages in service.

Similar content being viewed by others

References

H. Cohen, G.F.C. Rogers, H.I.H. Saravanamuttoo, Gas Turbine Theory (Longman Group Limited, Essex, 1996)

T. Giampaolo, The Gas Turbine Hand Book: Principles and Practices, 2nd edn. (Fairmont Press Inc., New York, 2003)

S.J. Gallimore, Axial flow compressor design. Proc. Inst. Mech. Eng. 213(5), 437–449 (1999)

A. Keskin, D. Bestle, Application of multiobjective optimization to axial compressor preliminary design. Aerosp. Sci. Technol. 10(7), 581–589 (2006)

M.P. Boyce, Gas Turbine Engineering Handbook, 2nd edn. (Butterworth-Hienemann, New York, 2003)

K. Ghorbanian, M. Gholamrezaei, Axial Compressor Performance Map Prediction Using Artificial Neural Network, (ASME Turbo Expo 2007, GT2007-27165), pp. 1199–1208

R.P. Czachor, Unique Challenges for Bolted Joint Design in High-Bypass Turbofan Engines, vol. 127 (ASME, 2005)

R. Warikoo, R. Beaulieu, B. Mason, Stress analysis of turbo machinery discs having complex bolted flange design features. Proceedings of ASME Turbo Expo 2002

F. Ahmad, A.V. Mirzamoghadam, Disc design and air system comparison between a single and a two stage high pressure turbine aero engine. Proceedings of ASME Turbo Expo, 2000-GT-0610

R.S.J. Corran, S.J. Williams, Lifing methods and safety criteria in aero gas turbine engines. Eng. Fail. Anal. 14, 518–528 (2007)

J.O. Peters, R.O. Ritchie, Influence of foreign-object damage on crack initiation and early crack growth during high-cycle fatigue of Ti-6Al-4V. Eng. Fract. Mech. 67, 193–207 (2000)

P.G. Frankel, P.J. Withers, M. Preuss, H.T. Wang, J. Tong, D. Rugg, Residual stress fields after FOD impact on flat and aerofoil-shaped leading edges. Mech. Mater. 55, 130–145 (2012)

A.N. Servetnik, Energy-based method for gas turbine engine disk burst speed calculation. Proceedings of 28th International Congress of the Aeronautical Sciences (2012)

M. Maziere et al., Overspeed burst of elastoviscoplastic rotating disks—part I: analytical and numerical stability analyses. Eur. J. Mech. 28, 36–44 (2009)

P. Blüml et al., Qualification of Life Extension Schemes for Engine Components. RTO Meeting Proceedings 17 (1999)

D. Eylon, J.A. Hall, Fatigue behavior of beta processed titanium alloy IMI 685. Metall. Trans. A 8(6), 981–990 (1977)

R. Boyer, G. Welsch, E.W. Collings, Materials Properties Handbook: Titanium Alloys (ASM International, Materials Park, 1994)

ASM, Metals Handbook, vol. 2—Properties and Selection: Nonferrous Alloys and Special-Purpose Materials (ASM International 10th edn. 1990)

G.E. Dieter, D. Bacon, Mechanical Metallurgy (McGraw Hill Book Company Inc., New York, 1986)

A. Mitchell, Melting, casting and forging problems in titanium alloys. Mater. Sci. Eng. A 243(1–2), 257–262 (1998)

Y.V.R.K. Prasad, T. Seshacharyulu, Processing maps for hot working of titanium alloys. Mater. Sci. Eng. A 243(1–2), 82–88 (1998)

MIL-E-5007 D/E (AS), Military Specification for Engines, Aircrafts, Turbojet and Turbofan (1983)

B.H. Maruthi et al., Modified disc model for over-speed burst margin with thermal load and disc speed corrections and compared with FE model. Int. J. Recent Technol. Eng. 1(2), 26–31 (2012)

R. Ehrich, High speed balance procedure. Proceedings of the Ninth Turbomachinery Symposium, pp. 25–31

H. Schultz, Electron Beam Welding (Abington Publishing Woodhead Publishing Limited, Abington, 2004)

Larry Jeffus, Welding: Principle and Application (Delmer, New York, 2012)

P.I. Petrov, Electron Beam Welding Process, 7th International Conference on Trends in Welding Research (2005)

Defence Standard 00-970, Part 11/1, Annex A

Military Standard MIL-STD-1783 Engine Structural Integration Program (1984)

FAA Advisory Circular, Calibration test, Endurance test and Teardown inspection for turbine engine certification, AC No. 33.87-1 (2006)

B.J. McDonnell, The Application of a Design Validation System and Accelerated Mission Testing to a Gas Turbine Engine Development. SAE Technical Paper, Doc. No. 780991 (1980)

R. Ebbs, Is the Traditional 150 Hour Endurance Test Outdated? Rolls-Royce Limited (1985)

J. Blanton, D, Wisler, A Brief History of Aircraft Engine Development at General Electric, 43rd Joint Propulsion Conference and Exibit, Cincinnati, 2007, AIAA 2007-5339

Quentin Benetuillere, Revision of the Aircraft Engine Preliminary Design Platform of First Level, MS Thesis EGI-2014-080MSC EKV1050 (KTH School of Industrial Engineering and Management, Stockholm, 2014)

Dominique Leguillon, Strength or toughness? A criterion for crack onset at a notch. Eur. J. Mech. A 21(1), 61–72 (2002)

Acknowledgment

The authors are very grateful to the General Manager, Engine Division, Hindustan Aeronautics Limited and the Chief Executive (Airworthiness), CEMILAC for their kind permission for publishing this paper. The authors are also very thankful to the Regional Director, Aeronautical Quality Assurance (Engines) for his help and support during this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mishra, R.K., Prakash, L. & Mistry, S.N. Qualification Approach of a High-Pressure Compressor Drum of a Military Turbofan Engine for Structural Integrity and Life. J Fail. Anal. and Preven. 15, 503–512 (2015). https://doi.org/10.1007/s11668-015-9963-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-015-9963-2