Abstract

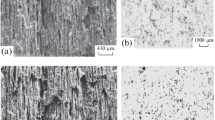

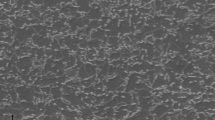

The method for determining the height of the surface microirregularities by means of a pseudostereopair, which can be used to determine the geometry of the start zone of the brittle separation crack, is completed and automated. The possibility of using the proposed method for investigating the stretch zone of compact specimens of the OSL steel is considered. The stretch zone of the railway axis steel is investigated using the proposed technique.

Similar content being viewed by others

References

U. Zerbst, K. Madler, H. Hintze, Fracture mechanics in railway applications—an overview. Eng. Fract. Mech. 72, 163–194 (2005)

S.J. Kwon, D.H. Lee, J.W. Seo, S.T. Kwon, Safety margin evaluation of railway wheel based on fracture scenarios. Int. J Railway 544, 280–285 (2012)

M.R. Zhang, H.C. Gu, Microstructure and mechanical properties of railway wheels manufactured with low-medium carbon Si-Mn-Mo-V steel. J. Univ. Sci. Technol. Beijing 15, 125–131 (2008)

C. Klinger, D. Bettge, Axle fracture of an ICE3 high speed train. Eng. Fail. Anal. 35, 66–81 (2013)

Y.X. Zhao, Fatigue crack growth law covering threshold and fracture toughness for railway LZ50 axle steel. Adv. Mat. Res. 544, 280–285 (2012)

P.O. Maruschak, A.P. Sorochak, A. Menou, O.V. Maruschak, Regularities in macro- and micromechanisms of fatigue crack growth in a bimetal of continuous caster rolls. Case Stud. Eng. Fail. Anal. 1, 165–170 (2013)

M. Khokhlov, A. Fischer, D. Rittel, Multi-scale stereo-photogrammetry system for fractographic analysis using scanning electron microscopy. Exp. Mech. 52, 975–991 (2012)

A. Ya, Krasovskii stereoscopic measurements of the stretched zone as an independent method for metal fracture toughness control. Strength Mater. 32, 476–479 (2000)

P.V. Yasniy, I.B. Okipnyi, P.O. Maruschak, S.V. Panin, I.V. Konovalenko, Crack tip strain localisation on mechanics of fracture of heat resistant steel after hydrogenation. Theor. Appl. Fract. Mech. 63–64, 63–68 (2013)

D.A. Sakseev, E.M. Ershenko, S.V. Baryshev, A.V. Bobyl’, D.V. Agafonov, Deep microrelief measurement and stereo photography in scanning electron microscopy. Tech. Phys. 56, 127–131 (2011)

A.J. Krasowsky, V.A. Vainshtok, On a relationship between stretched zone parameters and fracture toughness of ductile structural steels. Int. J. Fract. 17, 579–592 (1981)

P.O. Maruschak, I.V. Konovalenko, E.V. Maruschak, A.P. Sorochak, Automated method for stereometric study of fatigue failure mechanisms. Metallurgist 58, 43–47 (2014)

V.A. Stepanenko, A.S. Shtukaturova, P.V. Yasnyi, Stereofractographic investigation of the zone of static advance and the dynamic jump of a fatigue crack in casing steel. Soviet Mater. Sci. 19, 550–556 (1983)

H. Alihosseini, K. Dehghani, Modeling and failure analysis of a broken railway axle: effects of surface defects and inclusions. J. Fail. Anal. Prev. 10, 233–239 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maruschak, P.O., Sorochak, A.P. & Konovalenko, I.V. Stereoscopic Analysis of the Stretch Zone of a Steel Specimen Cut Out of a Railway Axle and Tested for Static Fracture Toughness. J Fail. Anal. and Preven. 15, 436–440 (2015). https://doi.org/10.1007/s11668-015-9956-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-015-9956-1