Abstract

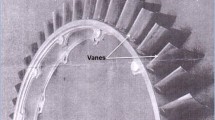

A locomotive turbocharger assembly suffered from destruction during a trial operating for 120 h. The damaged components include worm-housing, impeller blades and impeller-cover, main-shaft, bearing-sleeve, and main-shaft bolts. Fracture, deformation, and wear to varying degrees occurred on the components. The damage and fractography features on the failed components were investigated to identify the troublemaker in this incident and the root cause of turbocharger destruction. The investigation indicates that thread stripping on the wall of bolt holes on the flange at the inlet end of worm-housing induced the destruction of the whole turbocharger assembly. The specified material of worm-housing is gray cast iron (HT 250) and the specified low limit of tensile strength is 250 MPa. Unexpectedly, the tensile strength of the failed worm-housing material is about 70% of the specified low limit. The low strength of worm-housing material is mainly responsible for thread stripping of the bolt holes on the flange. The carbon content of worm-housing material exceeds the specified upper limit. Excessive graphite and long and thick graphite flakes in the worm-housing material resulting from high carbon content or maybe from unsuitable foundry practices led to low hardness and low strength of worm-housing material.

Similar content being viewed by others

References

Grey Iron Castings: China Standard, GB/T 9439-2010, 2010 (in Chinese)

ASM Handbook: Fractography, vol. 12, 10th edn. (ASM International, Metals Park, 1990)

Metallographic Test for Gray Cast Iron: Microstructure Irons—Part I: Graphite Classification by Visual Analysis. China Standard, GB/T 7216-2009, 2009 (in Chinese)

M.H. Cho, S.J. Kim, R.H. Basch, J.W. Fash, H. Jang, Tribological study of grey cast ion with automotive bake lining: the effect of rotor microstructure. Tribol. Int. 36, 537–545 (2003)

L. Álvarez, C.J. Luis, I. Puertas, Analysis of the influence of chemical composition on the mechanical and metallurgical properties of engine cylinder blocks in grey cast iron. J. Mater. Process. Technol. 153–154, 1039–1044 (2004)

O.P. Singh, S. Mohan, K. Venkata Mangaraju, M. Jayamathy, R. Babu, Thermal Seizures in Automotive Drum Brakes. Eng. Fail. Anal. 17, 1155–1172 (2010)

K. Aslantas, S. Talas, S. Tasgetiren, Fracture of a compressor rotor made from grey cast iron. Eng. Fail. Anal. 11, 369–373 (2004)

J.R. Davis, K.M. Mills, S.R. Lampman, Metals Handbook, vol. 1, Properties and Selection: Irons, Steels and High-Performance Alloys, 10th edn. (ASM International, Materials Park, 1990)

Acknowledgments

The project is supported by “the Fundamental Research Funds for the Central Universities (No. 3132014323)”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Z., Xu, X. & Yu, H. Failure Analysis of the Related Components of a Locomotive Turbocharger. J Fail. Anal. and Preven. 15, 407–416 (2015). https://doi.org/10.1007/s11668-015-9949-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-015-9949-0