Abstract

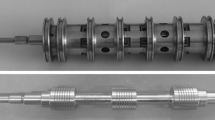

A failure analysis study was carried out on AISI 204 Cu stainless steel full-threaded fasteners and end-threaded SS 316L fasteners used in a deep water work class ROV system. The AISI 204 Cu stainless steel full-threaded fasteners were used in a Ti–6Al–4V alloy pressure case. The end-threaded SS 316L fasteners were used for attaching the bottom fender in the tether management system (TMS) made of Al 6061-T6 alloy. The mechanical property of both the fasteners was found to be within standard specification. The SEM study of the full-threaded fasteners revealed that the corrosion pit formation in the unfractured interface area is the cause of crack initiation. Subsequently, the crack propagated by stress corrosion cracking and finally, failed by fast overload cleavage fracture. It can be reasoned that a lower wt.% of molybdenum in AISI 204 Cu stainless steel reduced the pitting corrosion resistance of the full-threaded fasteners. The end-threaded fastener failed by stress corrosion cracking, but corrosion pit was not found in the fracture surface, due to the lack of its interface area with the unfractured region. It can be inferred that the chlorine ions of seawater break the oxide film of stainless steel bolts to form corrosion pits. These corrosion pits act as a stress concentration point to initiate a crack, and subsequently the bolts fail by stress corrosion cracking, showing a brittle appearance.

Similar content being viewed by others

References

J. Selvakumar Manecius, R. Ramesh, A.N. Subramanian, D. Sathianarayanan, G. Harikrishnan, V.K. Jayakumar, D. Muthukumaran, M. Murugesan, E. Chandresekaran, S. Elangovan, V. Doss Prakash, A. Vadivelan, M. Radhakrishnan, S. Ramesh, G.A. Ramadass, M.A. Atmanand, S. Sergey, A. Alexey, in: Proceedings of the twentieth international offshore and polar engineering conference (ISOPE-2010), (Beijing, China, 20–25 June 2010), pp. 206–212

F 606 M, Standard test method for determining the mechanical properties of externally and internally threaded fasteners, washers and rivets, Annual Book of ASTM Standards (2004)

J. Magee, Development of Type 204 Cu Stainless, A Low-cost Alternate to Type 304, Technical Article (Carpenter Technology Corporation, Wyomissing, 2001)

AISI 204Cu, Long product stainless steel grade sheet, North American stainless (2010)

S. Elbeik, A.C.C. Tseung, A.L. Mackay, The formation of calcareous deposits during the corrosion of mild steel in seawater. Corros. Sci. 26, 669–680 (1986)

W.H. Hartt, C.H. Culberson, S.W. Smith, Calcareous deposits on metal surfaces in seawater—a critical review. Corrosion 40, 609–618 (1984)

R.W. Ross, Alloys for Marine Fasteners, CORROSION 2000, March 26–31, (NACE International, Orlando, 2000

H.E. Deverell, J.R. Maurer, Stainless Steels in Seawater. Mater. Perform. 17, 15–20 (1978)

A.J. Sedricks, Corrosion of Stainless Steels (Wiley, NewYork, 1979), p. 300

J.R. Davis, Corrosion: Understanding the Basics (ASM International, NewYork, 1979), p. 563

F 593, Standard Specification for Stainless Steel Bolts, Hex Cap Screws, and Studs, Annual Book of ASTM Standards (2004)

Acknowledgments

The authors wish to acknowledge the support extended by the Marine Biotechnology team for their help during the SEM analysis. The authors also thank Dr. M. A. Atmanand, Director, NIOT, Chennai, for his support and encouragement. This work was funded by the Polymetallic Manganese Nodule (PMN) Programme and the Gas Hydrate Programme of the Ministry of Earth Sciences, Government of India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chowdhury, T., Sathianarayanan, D., Dharani, G. et al. Failure Analysis of Fasteners in a Remotely Operated Vehicle (ROV) System. J Fail. Anal. and Preven. 15, 915–923 (2015). https://doi.org/10.1007/s11668-015-0034-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-015-0034-5