Abstract

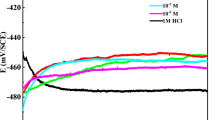

The inhibitive action of potassium iodide (KI) on the corrosion of Al–Si/SiC particulate composite in 3.65% NaCl solution was investigated using gravimetric and potentiodynamic polarization techniques at 298 K. The results showed that KI in NaCl-aluminum alloy/SiC composite environment decreased the corrosion rate at all the concentrations considered. Inhibitor efficiencies (IEs) of 97.17, 97.34, and 97.57% with 0.5 g/v addition using gravimetric method were achieved after 92, 196, and 288 h of exposure times, respectively. The IEs from the potentiodynamic polarization method under both conditions (uninhibited/inhibited) were significantly enhanced. The high-resolution scanning electron microscopy for surface morphology of the as-corroded, uninhibited specimens showed the formation of pits and cracks compared with the as-corroded inhibited specimens. The addition of KI as corrosion inhibitor indicates increased potential value, % IE, and polarization resistance value with the decreasing current density. The two methods employed for the corrosion assessment of the composite were in agreement, and mixed-type corrosion has been demonstrated to occur which followed Langmuir adsorption isotherms.

Similar content being viewed by others

References

I. Grigorios, K.R. Pradeep, M. Angeliki, V. Charalampos, D.D. John, K. Nikolaos. Word of Coal Ash (WOCA) conference, May 9–12, 2011, Denvere, CO, 2011

S.A. Sajjadi, P.M. Torabi, H.R. Ezatpour, A. Sedghi, J. Alloy. Compd. 511, 226–231 (2012)

M. Ali, O.S. Mohsen, J. Mater. Eng. Perform. 21(2), 247–252 (2012)

G.E. Mangin, J.A. Isasscs, J.P. Clark, J. Met. 48(2), 49–51 (1996)

Y.L. Saraswathi, S. Das, D.P. Mondal, Corrosion 57(7), 643–653 (2001)

M. Ramachandra, K. Radhakrishna, J. Mater. Sci. Poland. 24, 334–349 (2006)

J. Zhahaviand, H.J. Wagner, K. Natesan, (ed.), Proceedings of Symposium, Fall meeting of Metals society of AIME, St Louis, Missouri, American Institute of Mining, Metallurgical, and Petroleum Engineers, Warrendale, PA, 1978, pp. 226

M. Aylor, P.J. Morgan, J. Electrochem. Soc. 132, 1277 (1985)

C.K. Fang, C.C. Huang, J. Chuang, Metall. Mater. Trans. 30A, 643–651 (1999)

F. Asuke, S.A. Yaro, O.B. Oloche, J. Appl. Sci. Res. 6(11), 1759–1765 (2010)

A.M. Al-Turkustani, S.T. Arab, L.S.S. Al-Qarni, Orient. J. Chem. 26(2), 437 (2010)

J. Halambek, K. Berkovic, J. Vorkapic-Furac, Corros. Sci. 52, 3978–3983 (2010)

Acknowledgments

The authors wish to acknowledge the equipment facility provided by the Department of Chemical and Metallurgical Engineering, Tshwane University of Technology, Pretoria for conducting the electrochemical corrosion test.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Asuke, F., Abdulwahab, M., Fayomi, O.S.I. et al. Inhibitive Action of Potassium Iodide on the Corrosion of Stir-Cast Al–Si/SiC in NaCl-KI Interface. J Fail. Anal. and Preven. 15, 822–827 (2015). https://doi.org/10.1007/s11668-015-0015-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-015-0015-8