Abstract

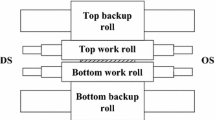

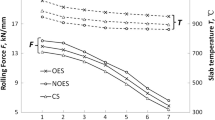

Rolls are key components in hot strip mill. Roll wear and fatigue are inevitable phenomena during hot-rolling process. Finite element (FE) analysis shows that roll profiles, especially work roll wear profile, have significant effects on contact stress distributions. Long-term effect of huge contact stress peaks in roll sides is the main factor for roll spallings. In order to solve serious roll spallings, a design process of backup roll profile is proposed to homogenize contact stress distributions. FE calculation demonstrates the superiority of the new profile in eliminating stress peaks. Industry application also manifests its good performance in preventing roll spalling and improving roll wear.

Similar content being viewed by others

References

M.S. Prasad, S.K. Dhua, C.D. Singh, A. Ray, Genesis of spalling in tandem mill work-rolls: Some observations in microstructural degeneration. J. Fai. Anal. Prev. 5(6), 30–38 (2005)

R. Colás, J. Ramírez, I. Sandoval, J.C. Morales, L.A. Leduc, Damage in hot rolling work rolls. Wear 230(1), 56–60 (1999)

A. Ray, M.S. Prasad, P.K. Barhai, S.K. Mukherjee, Microstructural characteristics of prematurely failed cold-strip mill work-rolls: Some observations on spalling susceptibility. J. Mater. Eng. Perform. 14(2), 194–202 (2005)

P. Sinha, S.S. Indimath, G. Mukhopadhyay, S. Bhattacharyya, Failure of a work roll of a thin strip rolling mill: a case study. Procedia Eng. 86, 940–948 (2014)

W.S. Dai, M. Ma, J.H. Chen, The thermal fatigue behavior and cracking characteristics of hot-rolling material. Mater. Sci. Eng. A 448(1–2), 25–32 (2007)

R.D. Mercado-Solis, J. Talamantes-Silva, J.H. Beynon, M.A.L. Hernandez-Rodriguez, Modelling surface thermal damage to hot mill rolls. Wear 263(7–12), 1560–1567 (2007)

X. Qin, D. Sun, L. Xie, Q. Wu, Hardening mechanism of Cr5 backup roll material induced by rolling contact fatigue. Mater. Sci. Eng. A 600, 195–199 (2014)

M. Nilsson, M. Olsson, Microstructural, mechanical and tribological characterisation of roll materials for the finishing stands of the hot strip mill for steel rolling. Wear 307(1–2), 209–217 (2013)

G. Wang, S. Qu, F. Lai, X. Li, Z. Fu, W. Yue, Rolling contact fatigue and wear properties of 0.1C–3Cr–2W–V nitrided steel. Int. J. Fatigue 77, 105–114 (2015)

O. Joos, C. Boher, C. Vergne, C. Gaspard, T. Nylen, F. Rezaï-Aria, Assessment of oxide scales influence on wear damage of HSM work rolls. Wear 263(1–6), 198–206 (2007)

G. Yang, J. Cao, J. Zhang, S. Jia, R. Tan, Backup roll contour of a SmartCrown tandem cold rolling mill. J. Univ. Sci. Technol. Beijing 15(3), 357–361 (2008)

W. Li, Z. Guo, J. Yi, X. Liu, Optimization of roll shifting strategy of alternately rolling in hot strip mill. J. Iron Steel Res. Int. 19(5), 37–42 (2012)

J. Brouzoulis, Wear impact on rolling contact fatigue crack growth in rails. Wear 314(1–2), 13–19 (2014)

F.J. Martínez, M. Canales, J.M. Bielsa, M.A. Jiménez, Relationship between wear rate and mechanical fatigue in sliding TPU-metal contacts. Wear 268(3–4), 388–398 (2010)

R.D. Mercado-Solis, J.H. Beynon, Simulation of thermal fatigue in hot strip mill work rolls. Scand. J. Metall. 34(3), 175–191 (2005)

F.J. Belzunce, A. Ziadi, C. Rodriguez, Structural integrity of hot strip mill rolling rolls. Eng. Fail. Anal. 11(5), 789–797 (2004)

Q. Dong, J. Cao, H. Li, Y. Zhou, T. Yan, W. Wang, Analysis of spalling in roughing mill backup rolls of wide and thin strip hot rolling process. Steel Res. Int. 86(2), 129–136 (2015)

H. Choi, D. Lee, J. Lee, Optimization of a railway wheel profile to minimize flange wear and surface fatigue. Wear 300(1–2), 225–233 (2013)

X.L. Chen, J. Zhang, Q.D. Zhang, C.S. Wang, Q. Yang, B.R. Liu, L. Wang, G.C. Wei, S.Q. Huang, J.A. Yang, Development in profile and flatness control system of hot strip mills. Iron Steel 35(7), 28–33 (2000). (in Chinese)

J.G. Cao, S.J. Liu, J. Zhang, P. Song, T.L. Yan, Y.Z. Zhou, ASR work roll shifting strategy for schedule-free rolling in hot wide strip mills. J. Mater. Process. Tech. 211(11), 1768–1775 (2011)

Acknowledgment

The authors would like to acknowledge the financial support provided by the Specialized Research Fund for the Doctoral Program of Higher Education of China (Grant No. 20120006110015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dong, Q., Cao, Jg. & Wen, D. Spalling Prevention and Wear Improvement of Rolls in Steel Strip Hot-Rolling Process. J Fail. Anal. and Preven. 15, 626–632 (2015). https://doi.org/10.1007/s11668-015-0011-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-015-0011-z