Abstract

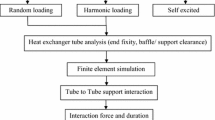

This paper presents a failure analysis performed to investigate the leak of heat exchanger tubes. The objectives of the investigation are to identify the failure mechanism and possible contributing factors and suggest corrective actions to prevent reoccurrence of similar failure. Thorough failure analysis showed that sulfur was obviously detected on both tube side surfaces (OD and ID). Probably, the source of this sulfur can be DMDS or the feedstock. The mechanism of the failures occurred in the heater exchanger tubes is due to external thinning that was most likely caused by combination of impact fretting and corrosion. It is recommended to ensure that the system is dry in heat exchangers shell side. Closely monitor sulfur contents in the heat exchanger stream. If possible, monitor the thickness of all tubes, especially area under/near the baffle to tube interface, during scheduled turnarounds to reduce the possibility of sudden failures. The condition of the other heat exchangers should be assessed. Ensure that the tube bundle as a whole “tightens up” and will act as one rigid entity. Anti-Vibration Supports might be helpful to be inserted between tubes and close to the baffle plates to mitigate the vibration as a result of fluid flow.

Similar content being viewed by others

References

API 571, Damage Mechanisms Affecting Fixed Equipment in the Refining Industry, Recommended Practice 571, 1st edn, December 2003

ASTM A179, Standard Specification for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes (ASTM International, West Conshohocken, 2005)

W.T. Becker, Fracture Appearance and Mechanisms of Deformation, Failure Analysis and Prevention, vol 11 (ASM Handbook, ASM International, Metals Park, 2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shahrani, S., Al-Subai, S. Failure Analysis of Heat Exchanger Tubes. J Fail. Anal. and Preven. 14, 790–800 (2014). https://doi.org/10.1007/s11668-014-9888-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-014-9888-1