Abstract

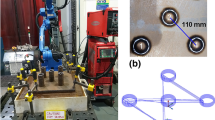

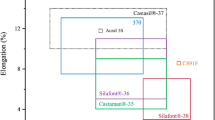

The ECAP process is a promising technique for imparting large plastic deformation and breaking down the ingot cast structure without a resultant decrease in cross-sectional area. In the present study, the suitability of this technique for processing cast Al–5Zn–1Mg tubular specimens at room temperature has been investigated. Tubular specimens were extruded through an ECAP die with an angle of 150° between the two intersecting channels without a back pressure. Sand was used as a mandrel during pressing. The tubular specimens failed miserably in the first pass itself. A failure analysis was carried out using SEM, and cause for failure was determined.

Similar content being viewed by others

References

I. Yoshinori, F. Minoru, H. Zenji, N. Minoru, L. Terence, Structural characteristics of ultrafine-grained aluminum produced using equal-channel angular pressing. Metall. Mater. Trans. A 29, 2245–2252 (1998)

R.Z. Valiev, T.G. Langdon, Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 51, 881–981 (2006)

V.M. Segal, Materials processing by simple shear. Mater. Sci. Eng. 197, 157–164 (1995)

Y.Y. Wang, P.L. Sun, P.W. Kao, C.P. Chang, Effect of deformation temperature on the microstructure developed in commercial purity aluminum processed by equal channel angular extrusion. Scr. Mater. 50, 613–617 (2004)

V.V. Stolyarov, V.V. Latysh, V.A. Shundalov, D.A. Salimonenko, R.K. Islamgaliev, R.Z. Valiev, Influence of severe plastic deformation on aging effect of Al–Zn–Cu–Zr alloy. Mater Sci. Eng. A 339, 234–236 (1997)

Y. Iwahashi, Z. Horita, M. Nemoto, T.G. Langdon, An investigation of microstructural evolution during equal-channel angular pressing. Metall. Mater. Eng. A 45, 4733–4741 (1997)

N. Kiyotaka, Z. Horita, M. Nemoto, T.G. Langdon, Development of a multi-pass facility for equal-channel angular pressing to high total strains. Mater. Sci. Eng. A 281(1–2), 82–87 (2000)

I.V. Alexandrov, G.I. Raab, L.O. Shestakova, R.Z. Valiev, R.J. Dowding, in ed. by M.S. Greenfield, J.J. Oakes. Tungsten, Hard Metals and Refractory Alloys, vol. 5 (Princeton, Metal Powder Industries Federation, 2000), p. 7

M. Furui, H. Kitamura, H. Anada, T.G. Langdon, Acta Mater. 55, 1083 (2007)

A.V. Nagasekhar, U. Chakkingal, P. Venugopal, Candidature of equal channel angular pressing for processing of tubular commercial purity titanium. J. Mater. Process. Technol. 173, 53–60 (2006)

O. Dimitrov, R. Fromageau, C. Dimitrov, in Recrystallization of Metallic Materials, ed. by F. Haessner (Riederer-Verlag GMBH, Stuttgart, 1978), p. 137

W.H. Huang, C.Y. Yu, P.W. Kao, C.P. Chang, The effect of strain path and temperature on the microstructure developed in copper processed by ECAE. Mater. Sci. Eng. A 366, 221–228 (2004)

A. Yamashita, D. Yamaguchi, Z. Horita, T.G. Langdon, Influence of pressing temperature on microstructural development in equal-channel angular pressing. Mater. Sci. Eng A 287, 100–106 (2000)

Y.C. Chen, Y.Y. Huang, C.P. Chang, P.W. Kao, The effect of extrusion temperature on the development of deformation microstructures in 5052 aluminium alloy processed by equal channel angular extrusion. Acta Mater. 51, 2005–2015 (2003)

B.Q. Han, Z. Lee, D. Witkin, S. Nutt, E.J. Lavernia, Deformation behavior of bimodal nanostructured 5083 Al alloys. Metall. Mater. Trans. 36, 957–965 (2005)

D.H. Shin, Y.S. Kim, E.J. Lavernia, Formation of fine cementite precipitates by static annealing of equal-channel angular pressed low-carbon steels. Acta Mater. 49, 2387–2393 (2001)

Y. Fukuda, K. Oh-Ishi, Z. Horita, T.G. Langdon, Processing of a low-carbon steel by equal-channel angular pressing. Acta Mater. 50, 1359–1368 (2002)

V.M. Segal, V.I. Reznikov, A.E. Drobyshevskiy, V.I. Kopylov, Plastic working of metals by simple shear. Russ. Metall. 1, 99–105 (1981)

K. Lange (ed.), Hand Book of Metal Forming (McGraw Hill, New York, 1985), pp. 13–14

M. Rijesh, K. Geethalakshmi, K, Srinivasan, Determination of friction factor for Al–5Zn–1Mg at various temperatures. Paper presented at the international symposium on energy related materials, 45th National Metallurgist Day & 61st Annual Technical Meeting of the Indian Institute of Metals, p. 42, 13–16 November, (2007)

M. Rijesh, J. Valder, K. Geethalakshmi, A.O. Surendranathan, Deformation of Al–5Zn–1Mg in the temperature range of 303–673 K. Int. J. Eng. Sci. Manag. 2, 18–22 (2011)

S. Zhang, W. Hu, R. Berghammer, G. Gottinson, Microstructure evolution and deformation behavior of ultrafine-grained Al–Zn–Mg alloys with fine η′ precipitates. Acta Mater. 58, 6695–6705 (2010)

G.E. Dieter, Mechanical Metallurgy (McGraw-Hill Book Company, New York, 2001), pp. 254–258

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Valder, J., Rijesh, M. & Surendranathan, A.O. Failure Analysis of Cast Tubular Specimens of Al–5Zn–1Mg While Processing at Room Temperature by Equal Channel Angular Pressing (ECAP). J Fail. Anal. and Preven. 14, 690–695 (2014). https://doi.org/10.1007/s11668-014-9874-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-014-9874-7