Abstract

A locomotive diesel engine cardan-shaft fractured when trial test for 360 h. Fractographic investigation reveals that the failure mechanism of cardan-shaft is multiple origins fatigue fracture. The crack origins are situated on the external circle surface of the transition fillet root of the splined portion, which acts as a stress concentrator. The macro-structure segregation and corresponding inhomogeneous microstructure are presented in cardan-shaft material. And the presence of more ferrite and abnormal Widmannstätten structure ferrite in core microstructure led to the low core hardness (below the minimum value required). Therefore, the estimated fatigue endurance limit of the cardan-shaft material is lower than the expected value by approximately 20%. Along with the stress concentrator in transition fillet, the fatigue crack initiated and propagated under the torsion load and the axial tensile load, ultimately leading to premature fatigue fracture of cardan-shaft. The defective forging and the heat treatment processes should be responsible for the occurrence of defective microstructure and the consequence of low core hardness.

Similar content being viewed by others

References

ASM Handbook, Fractography, vol. 12, 9th edn. (ASM International, Metals Park, OH, 1987)

S. Bošnjak, N. Zrnić, A. Simonović, D. Momčilović, Failure analysis of the end eye connection of the bucket wheel excavator portal tie-rod support. Eng. Fail. Anal. 16, 740–750 (2009)

H.-S. Chen, P.-T. Tseng, S.-F. Hwang, Failure analysis of bolt on an end flange of a steam pipe. Eng. Fail. Anal. 13, 656–668 (2006)

S. Moradi, K. Ranjbar, Experimental and computational failure analysis of drillstrings. Eng. Fail. Anal. 16, 923–933 (2009)

Y. Murakami, Metal fatigue: effects of small defects and non-metallic inclusions (Elsevier, Oxford, 2002)

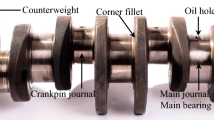

M.A. Alfares, A.H. Falah, A.H. Elkholy, Failure analysis of a vehicle engine crankshaft. J. Fail. Anal. Prev. 7, 12–17 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Zw., Xu, Xl. Fatigue Fracture of a Locomotive Diesel Engine Cardan-Shaft. J Fail. Anal. and Preven. 14, 405–411 (2014). https://doi.org/10.1007/s11668-014-9815-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-014-9815-5