Abstract

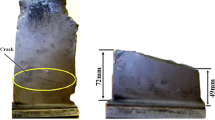

Gas turbine axial compressor blades are designed to withstand cyclic stress loading resulting of modal vibrations. However, when surface suffers from foreign object damage, a fatigue crack is likely to initiate. In this paper two failure case-studies of titanium alloy used for aeroderivative gas turbine compressor blades are presented. Both are related to a failure of first stage compressor blades coming from different turbine power ranges. Observed cracks were found at blade spans corresponding to modal vibrations.

Similar content being viewed by others

References

J.O. Peters, B.L. Boyce, X. Chen, J.M. McNaney, J.W. Hutchinson, R.O. Ritchie, On the application of the Kitagawa–Takahashi diagram to foreign-object damage and high-cycle fatigue. Eng. Fract. Mech. 69, 1425–1446 (2002)

J.O. Peters, R.O. Ritchie, Influence of foreign-object damage on crack initiation and early crack growth during high-cycle fatigue of Ti–6Al–4V. Eng. Fract. Mech. 67, 193–207 (2000)

T. Nicholas, Critical issues in high cycle fatigue. Int. J. Fatigue 21, S221–S231 (1999)

T. Nicholas, J.R. Barber, R.S. Bertke, Impact damage on titanium leading edges from small hard objects. Exp. Mech. 20, 357–364 (1980)

B.A. Cowles, High cycle fatigue in aircraft gas turbines—an industry perspective. Int. J. Fract. 80, 147–163 (1996)

T. Nicholas, J.R. Zuiker, On the use of the Goodman diagram for high cycle fatigue design. Int. J. Fract. 80, 219–235 (1996)

J.R. Larsen, B.D. Worth, C.G. Annis Jr, F.K. Haake, An assessment of the role of near-threshold crack growth in high cycle fatigue life prediction of aerospace titanium alloys under turbine engine spectra. Int. J. Fract. 80, 237–255 (1996)

W.D. Pridemore, Introduction to gas turbine failure analysis. General Electric Aviation Material and Process Engineering Department, Failure analysis training materials (2003)

M. Jasiczek, General Electric, Oil & Gas, Material and Process Engineering, Internal Report No. 201205000510Rev00FA

L. Kurys, General Electric Aviation Material and Process Engineering Department Internal Report No. FA2012-015838

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jasiczek, M., Szcześniak, D., Kaczorowski, J. et al. Investigation of Fatigue Failures of Titanium Alloy Blades Used in Compressor Modules of Aeroderivative Industrial Gas Turbines. J Fail. Anal. and Preven. 13, 689–696 (2013). https://doi.org/10.1007/s11668-013-9752-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-013-9752-8