Abstract

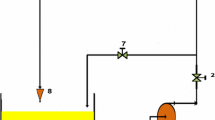

Cracking was found on the welded elbow at the bottom of rectifying tower in an alcohol evaporation system. In order to determine the cause of failure, a detailed analysis was conducted. The analysis included macroscopic observation for the failed tube and optical microscopy for the morphology of cracks. The characterization of fracture was analyzed by scanning electron microscopy, and the components subjected to the cracks were analyzed using energy-dispersive x-ray spectroscopy. Results revealed that the welded elbow had suffered damage from external chloride stress corrosion cracking (ECSCC). The environmental factor responsible for ECSCC is the chloride present in the dampish insulation. The stress factor is the result of the welding residual stress induced in the material which was used to fabricate the elbow.

Similar content being viewed by others

References

Vogelaere, F.D.: Corrosion under insulation. Process. Saf. Prog. 28, 30–35 (2009)

Bovard, T.: The problem of corrosion under thermal insulation. Mater. Perform. 41, 34–38 (2002)

ASM: Corrosion Under Thermal Insulation. Corrosion, ASM Handbook, vol. 13, 9th edn, pp. 1144–1148. ASM, Metals Park (1987)

Babakr, A., Al-Subai, S.: Under insulation stress corrosion cracking of process piping. In: Corrosion 2006, pp. 065001–065009. NACE, Orlando (2006)

Okubo, M.: External stress corrosion cracking of stainless steels caused by used by thermal insulation. Corros. Eng. 30(12), 705–715 (1981)

Shonohara, T., Shirai, M., Shinogaya, T.: External stress corrosion cracking (ESCC) of austenitic stainless steel. Mater. Perform. 24(6), 26–32 (1985)

Elshawesh, F., El Houd, A., El Raghai, O.: Technical note corrosion and cracking under insulation of type 304 stainless steel at ambient temperature. Corros. Eng. Sci. Technol. 38(3), 239–240 (2003)

Nakahara, M., Takahashi, M.: Case history of external stress corrosion cracking of stainless steel. Corros. Eng. 35(8), 467–470 (1986)

Handbook, Meta: Metallography and microstructures, vol. 9. ASM International, Materials Park (1986)

Kadry, S.: Corrosion analysis of stainless steel. Eur. J. Sci. Res. 22(4), 508–516 (2008)

Wu, M.D.: Corrosion and Tribology. Handbook of Materials Testing for Mechanical Engineering. China 2002, p. 233. (in Chinese)

Suresh, K.M., Sujata, M., Venkataswamy, M.A., et al.: Failure analysis of a stainless steel pipeline. Eng. Fail. Anal. 15(5), 497–504 (2008)

Sedriks, A.J.: Corrosion Monograph: Corrosion of Stainless Steels, vol. 15. A Wiley Interscience Publication, New York (1996)

Torchio, S.: Stress corrosion cracking of type AISI 304 stainless steel at room temperature; influence of chloride content and acidity. Corros. Sci. 20, 555–561 (1980)

Fontana, M.G.: Corrosion Engineering. McGraw-Hill, New York (1986)

Oberndorfer, M., Thayer, K., Kastenbauer, M.: Application limits of stainless steels in the petroleum industry. Mater. Corros. 55(3), 174–180 (2004)

Miller, J., Dupont, M.: Labels, gaskets, and chloride cracking of austenitic stainless steels. J. Fail. Anal. Prev. 11, 26–28 (2011)

Krishnan, K.N., Prasad, R.K.: Effect of microstructure on stress corrosion cracking behaviour of austenitic stainless steel weld metals. Mater. Sci. Eng. A 142(1), 79–85 (1991)

Williams, J., Evans, O.: The influence of insulation material on corrosion under insulation. In: NACE Northern Area Western Conference (2010)

Winnik, S.: Corrosion Under Insulation (CUI) Guidelines, 1st edn, pp. 92–94. Woodhead Publishing and Maney Publishing, Cambridge (2008)

Acknowledgments

The authors gratefully acknowledge the financial support provided by Ministry of Education of Jiangsu (08KJB430007) and Innovation Project for College Graduates of Jiangsu Province in China (CXLX12_0434).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bay, X.M., Tang, J.Q. & Gong, J.M. Failure Analysis for the Welded Elbow at the Bottom of the Rectifying Tower in the Alcohol Evaporation System. J Fail. Anal. and Preven. 13, 496–501 (2013). https://doi.org/10.1007/s11668-013-9703-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-013-9703-4