Abstract

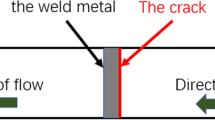

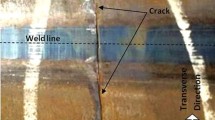

Telescopic front fork tube of the bike is manufactured by electrical resistance welding of pickled hot rolled strip followed by cold drawing. The fork undergoes cyclic loading during operation and is prone to crack along the weld. This paper presents the investigation of such a failure of fork at field. The investigation consists of visual inspection, chemical analysis, characterization of microstructure, and energy dispersive spectroscopy. The result of the analysis revealed that there was a pre-existing crack, known as hook crack, which lead to the cracking of the tube. The hook crack was slightly offset from the bond line, i.e., weld line between the edges of the cold drawn electrically welded seam. Metallographic examination exhibited that during field operation the pre-existing hook crack was surfaced out leading to crack in the pipe. Parallel separation/delamination due to upsetting of pipe edges during welding caused the “hook crack” formation.

Similar content being viewed by others

References

Quickel, G.T., Rollins, B.C., Beavers, J.A.: Analysis of seam weld related pipeline failures. Mater. Sci. Technol. 8, 514–523 (2008)

Bhadeshia, H.K.D.H., Honeycombe, R.W.K.: Steel Microstructure and Properties, pp. 299–301. Butterworth-Heinemann Publications, Boston (2011)

Koo, J.Y.: Welding Metallurgy of Structural Steels, p. 574. Metallurgical Society Inc, Warrendale (1987)

Rick Meade: Report submitted on non-destructive evaluation of low-frequency electric resistance welded pipe utilizing ultrasonic in-line inspection technology, Tubesscope Pipeline Services, Houston (2006)

ASM Hand-Book, vol. 11—Failure Analysis and Prevention, p. 191, 2005

Eaves, G.N., Cameron, S.R. et al: Hook Crack Reduction in ERW Line Pipe Steel. Steel making conferrence proceedings, pp. 521–528, 1992

Lancaster, J.F.: Metallurgy of Welding, pp. 222–223. Abington Publishing, Cambridge (1987)

Robert, K., Nichols, P.E.: The effects of steel mill practice on pipe and tube making. Thermatool Corp

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dey, A., Dhara, S., Bhttacharyya, T. et al. Cracking of Telescopic Front Fork Tube During Field Operation. J Fail. Anal. and Preven. 13, 292–297 (2013). https://doi.org/10.1007/s11668-013-9683-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-013-9683-4