Abstract

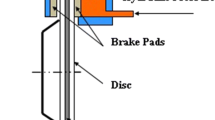

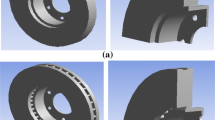

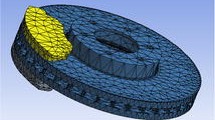

The main purpose of this study is to analyze the thermomechanical behavior of the dry contact between the brake disk and pads during the braking phase. The simulation strategy is based on computer code ANSYS11. The modeling of transient temperature in the disk is actually used to identify the factor of geometric design of the disk to install the ventilation system in vehicles. The thermal–structural analysis is then used with coupling to determine the deformation and the Von Mises stress established in the disk, i.e., the contact pressure distribution in pads. The results are satisfactory when compared to those of the specialized literature.

Similar content being viewed by others

References

Milenković, P.D., et al.: The influence of brake pads thermal conductivity on passenger car brake system efficiency. Therm. Sci. 14(Suppl.), S221–S230 (2010)

Belghazi, H.: Analytical solution of unsteady heat conduction in a two-layered material in imperfect contact subjected to a moving heat source, Ph.D. thesis, University of Limoges, Limoges (2010)

Nakatsuji, T., Okubo, K., Fujii, T., Sasada, M., Noguchi, Y.: Study on Crack Initiation at Small Holes of One-piece Brake Discs. Society of Automotive Engineers, Inc, Humble, 2002-01-0926 (2002)

Valvano, T., Lee, K.: An Analytical Method to Predict Thermal Distortion of a Brake Rotor. Society of Automotive Engineers, Inc, Humble, 2000-01-0445 (2000)

Hudson, M.D., Ruhl, R.L.: Ventilated Brake Rotor Air Flow Investigation. Society of Automotive Engineers, Inc, Humble, 1997-01-033 (1997)

Denape, J., Laraqi, N.: Aspect thermique du frottement: mise en évidence expérimentale et éléments de modélisation. Mec. Ind. 1, 563–579 (2000)

Hamraoui, M.: Thermal behaviour of rollers during the rolling process. Appl. Therm. Eng. 29(11–12), 2386–2390 (2009)

Hamraoui, M., Zouaoui, Z.: Modelling of heat transfer between two rollers in dry friction. Int. J. Therm. Sci. 48(6), 1243–1246 (2009)

Laraqi, N.: Velocity and relative contact size effect on the thermal constriction resistance in sliding solids. ASME J. Heat Transf. 119, 173–177 (1997)

Yapıcı, H., Genç, M.S., Özısık, G.: Transient temperature and thermal stress distributions in a hollow disk subjected to a moving uniform heat source. J. Therm. Stress 31, 476–493 (2008)

Laraqi, N., Alilat, N., Garcia-de-Maria, J.M., Baïri, A.: Temperature and division of heat in a pin-on-disc frictional device—exact analytical solution. Wear 266(7–8), 765–770 (2009)

Bauzin, J.G., Laraqi, N.: Simultaneous estimation of frictional heat flux and two thermal contact parameters for sliding solids. Numer. Heat Transf. 45(4), 313–328 (2004)

Baïri, A., Garcia-de-Maria, J.M., Laraqi, N.: Effect of thickness and thermal properties of film on the thermal behavior of moving rough interfaces. Eur. Phys. J. Appl. Phys. 26(1), 29–34 (2004)

Mijuca, D.M., Iberna, A.M., Medjo, B.I.: A new multifield finite element method in steady state heat analysis. Therm. Sci. 9(1), 111–130 (2005)

Zhang, L., Yang, Q., Weichert, D., Tan, N.: Simulation and analysis of thermal fatigue based on imperfection model of brake discs. Beijing Jiaotong Univ. PAMM Proc. Appl. Math. Mech. 9, 533–534 (2009)

Fiche U.I.C. 541-3: FREIN—Frein à disques et garnitures de frein à disques, 4e édition, 1 July 1993

Saumweber, E.: Temperaturberechnung in Bremsscheiben fürein beliebiges Fahrprogramm, Leichtbau der Verkehrsfahrzeuge, Heft 3, Augsburg (1969)

Cruceanu, C.: Frâne pentru vehicule feroviare (Brakes for railway vehicles). MATRIXROM (ed.), Bucureşti, ISBN 978-973-755-200-6 (2007)

Reimpel, J.: Technologie de freinage. Vogel Verlag, Würzburg (1998)

Gotowicki, P.F., Nigrelli, V., Mariotti, G.V.: Numerical and experimental analysis of a pegs-wing ventilated disk brake rotor, with pads and cylinders. In: 10th EAEC European Automotive Congress—Paper EAEC05YUAS04—P 5, June (2005)

Yu, H., et al.: Study on temperature distribution due to freezing and thawing at the Fengman concrete gravity dam. Therm. Sci. 15(Suppl. 1), s27–s32 (2011)

Sergerlind, L.J.: Applied Finite Element Analysis. Wiley, New York (1984)

Hinton, E., Owen, D.R.J.: An Introduction to Finite Element Computations. Pineridge Press, Swansea (1981)

Versteeg, H.K., Malalasekera, W.: An Introduction to Computational Fluid Mechanics. The Finite Volume Method. Pearson, Prentice Hall (1995)

Ansys v.11 User’Manual Guide. ANSYS, Inc., Houston, USA (1996)

Nouby, M., Srinivasan, K. (2009). Parametric studies of disc brake squeal using finite element approach. J. Mek. No. 29, 52–66 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Belhocine, A., Bouchetara, M. Thermal–Mechanical Coupled Analysis of a Brake Disk Rotor. J Fail. Anal. and Preven. 13, 167–176 (2013). https://doi.org/10.1007/s11668-012-9634-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-012-9634-5