Abstract

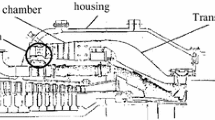

Outer shroud segments fabricated from a cast 310 stainless steel were found to have cracked following extended service. Several of these cracked shrouds were sent to the GE-Poland Materials Laboratory for metallurgical investigation with a view to determine the cause of cracking. Detailed investigation revealed cracking to be associated with a sigma phase, a brittle TCP intermetallic, which had developed over time during engine operation. Initial attempts to weld repair the cracks proved unsuccessful as cracks were discovered both during and after the weld repair procedure. A new weld repair procedure incorporating a pre-weld solution annealing heat treatment to remove the sigma phase before welding was successfully developed, thus alleviating the cracking concern.

Similar content being viewed by others

References

Hall, E.O., Algie, S.H.: The sigma phase. Metall. Rev 11, 61–88 (1966)

Hau, J., Seijas, A.: Sigma Phase Embrittlement of Stainless Steel in FCC Service, Corrosion 2006 – Nace International, paper no. 06578 (2006)

ASTM A240: Standard Specification for Chromium and Chromium–Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications (2011)

ASTM E 407-99: Standard Practice for Microetching Metals and Alloys (1999)

Acknowledgment

The authors would like to acknowledge to Dorota Szczesniak for aiding in publishing this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Didenko, T., Zak, M. Turbine Shroud Cracking Investigation and Repair. J Fail. Anal. and Preven. 12, 314–317 (2012). https://doi.org/10.1007/s11668-011-9501-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-011-9501-9